Maintenance

114

Pos: 42.26 /Übersc hriften/Überschri ften 2/U-Z/ZZinken tausc hen (im Reparaturfal l) @ 224\mod_1392293057621 _78.docx @ 1816928 @ 2 @ 1

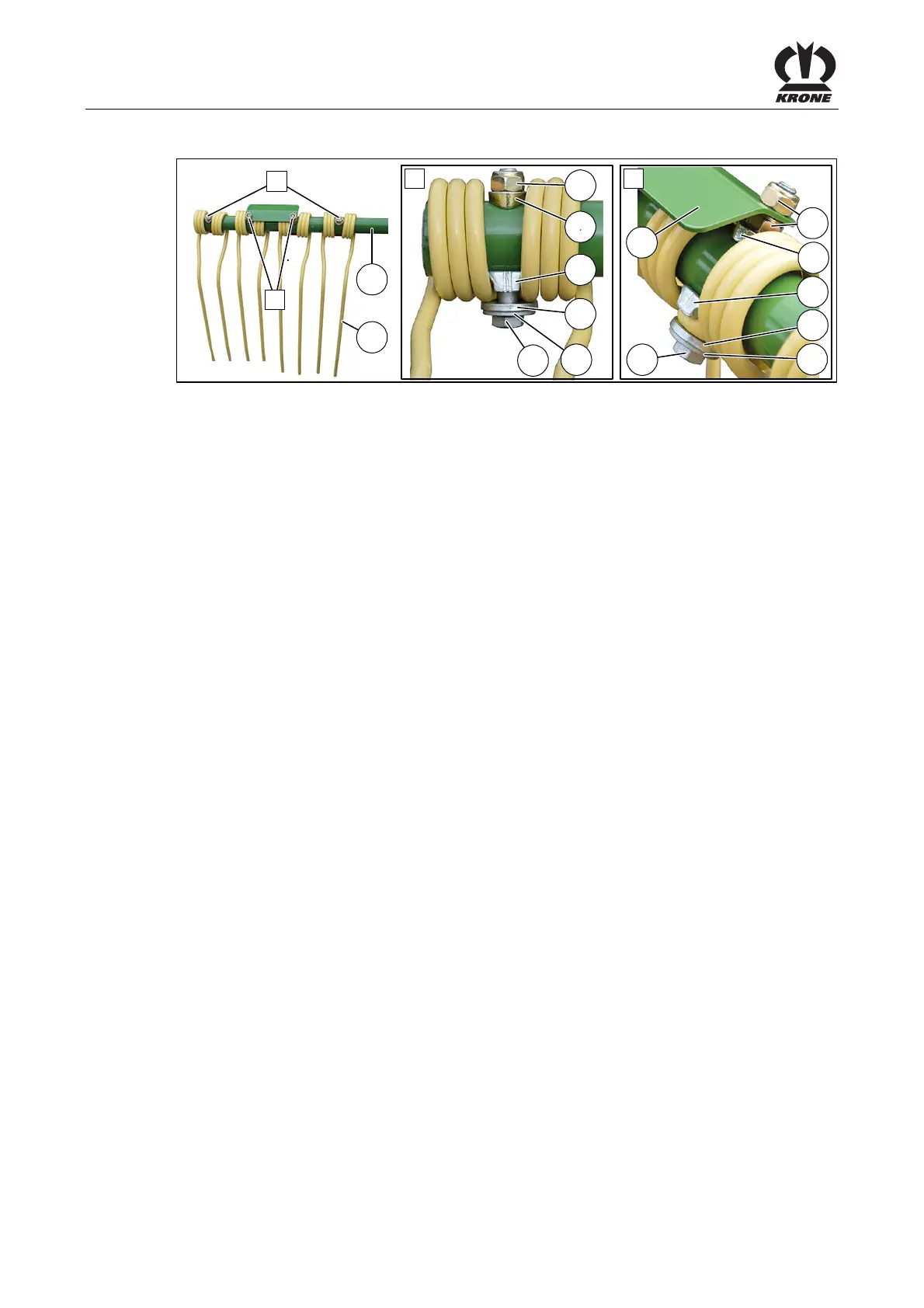

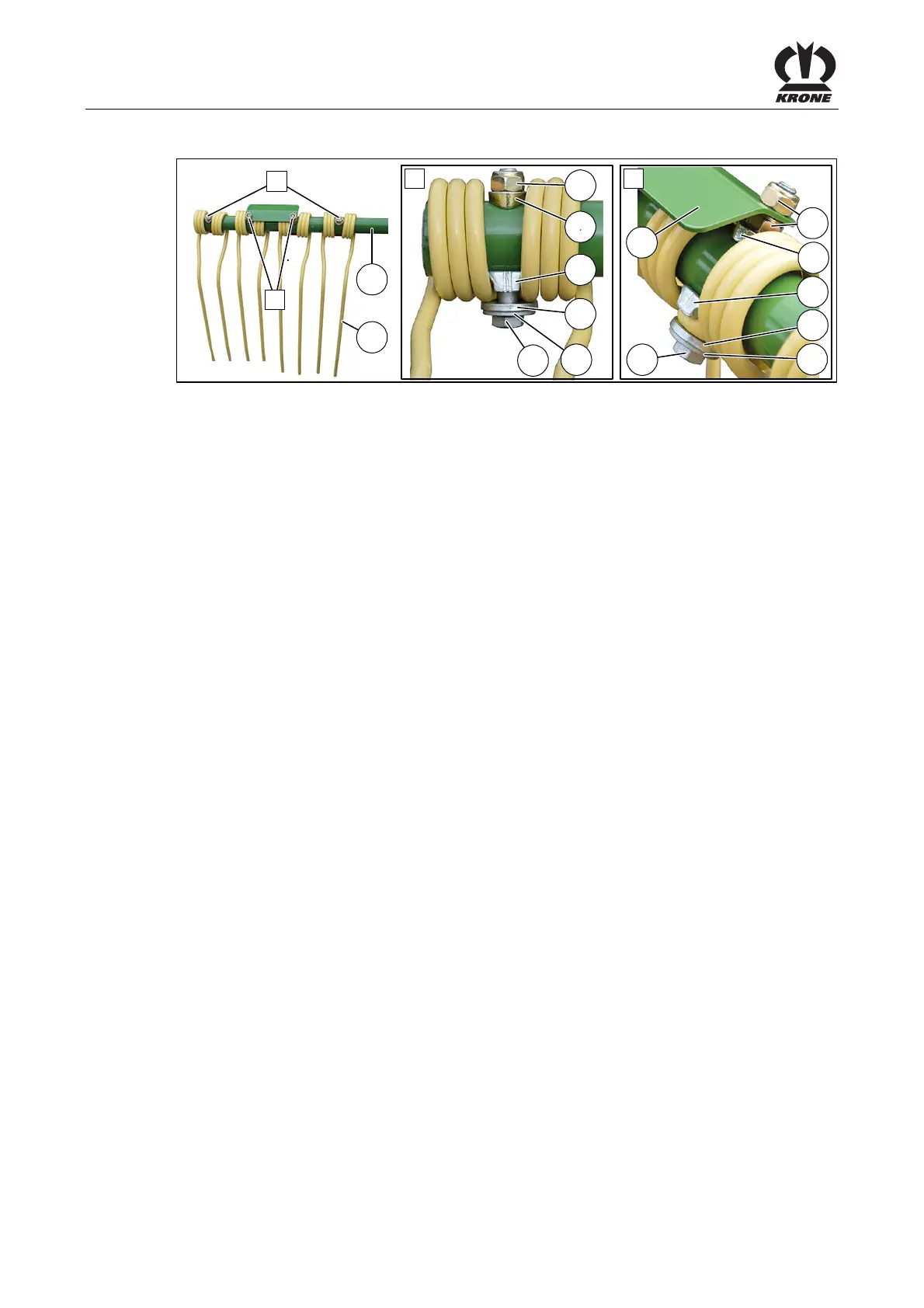

12.8 Replacing the tines (in case of repairs)

Pos: 42.27 /BA/W artung/Schwader/Zinken / Zinkenarme/Zinken ta uschen (im Reparaturf all) mit Abweisblech Bi ld mit Tabelle @ 357\mod_14387 54688087_78.doc x @ 2656307 @ @ 1

8

10

7

6

4

9

7

4

3

III

I

II

1

SW9070092_2

2

3

5

6

5

Fig. 66

1 Tines 2 Tine arm

3 Locknut M12 4 Base

5 Tine holder 6 Disc 13 x 35 x 5

7 Detent edged washer SKB 12 8 Hexagon head screw M12 x 85 10.9

9 Hexagon head screw M12 x 100 10 Deflection sheet

Adhesive (high-strength) (order no. 938 627

0)

Pos: 42.28 /BA/W artung/Schwader/Zinken / Zinkenarme/Zinken ta uschen (im Reparaturf all) mit/ ohne Abweisblec h_Text @ 381\mod_144 4051432268_78.doc x @ 2750485 @ @ 1

• To remove the broken tine, remove all tines in front of the broken tine.

• Remove the broken tine.

Mounting new tine

• Insert tine holder into tine. In doing so, make sure that the tine holder is positioned

according to the figure.

• Slide tine with tine holder on tine arm.

• Guide hexagon head screw with detent edged washer and disc from below through tine

holder and tine arm.

• Apply adhesive (high-strength) on threading overhang of hexagon head screw.

• Mount support, locknut and deflection sheet, if necessary.

• Raise the tines at their end and tighten locknut with tightening torque = 95 Nm.

• Proceed with all tines as described above.

Pos: 42.29 /Layout Module /---------------Seitenumbruch---------------- @ 0\mod_1196175311226_0. docx @ 4165 @ @ 1

Loading...

Loading...