LCC

7

4.2 Designation

LCC

-M 300-710.5M C M1

Pump Type l

Hydraulic Type l

Discharge Nozzle DN in mm l

Nominal Impeller Diameter in mm l

Mechanical Size l

Seal Type l

Options l

Material Code l

Hydraulic Type

M ............................................ Metal

R............................................. Elastomer

H............................................. Extra-Heavy Construction

Mechanical (Frame) Size

Seal Type

K ....................................... KE

B ....................................... Throat Bushing

M ....................................... Mechanical Seal

E ....................................... Expeller

Options

O ....................................... Open Shroud Impeller

A ....................................... Oil Lubricated

....................................... Grease Lubricated

T ....................................... Turn Down Impeller

U ....................................... Underwater Bearing Assembly

C ....................................... Elastomer Impeller

Nominal Flange and Impeller Diameters in mm (inches)

Designation Discharge Suction Impeller

LCC 50 - 230 50 ( 2” ) 80 ( 3” ) 225 ( 8.86” )

LCC 80 - 300 80 ( 3” ) 100 ( 4” ) 310 ( 12.22”)

LCC 100 - 400 100 ( 4” ) 150 ( 6” ) 395 ( 15.55”)

LCC 150 - 500 150 ( 6” ) 200 ( 8” ) 500 ( 19.69” )

LCC 200 - 610 200 ( 8” ) 250 ( 10”) 610 ( 24” )

LCC 250 - 660 250 ( 10”) 300 ( 12”) 660 ( 26” )

LCC 300 - 710 300 ( 12”) 350 ( 14”) 710 ( 27.95”)

4.3 Design Details

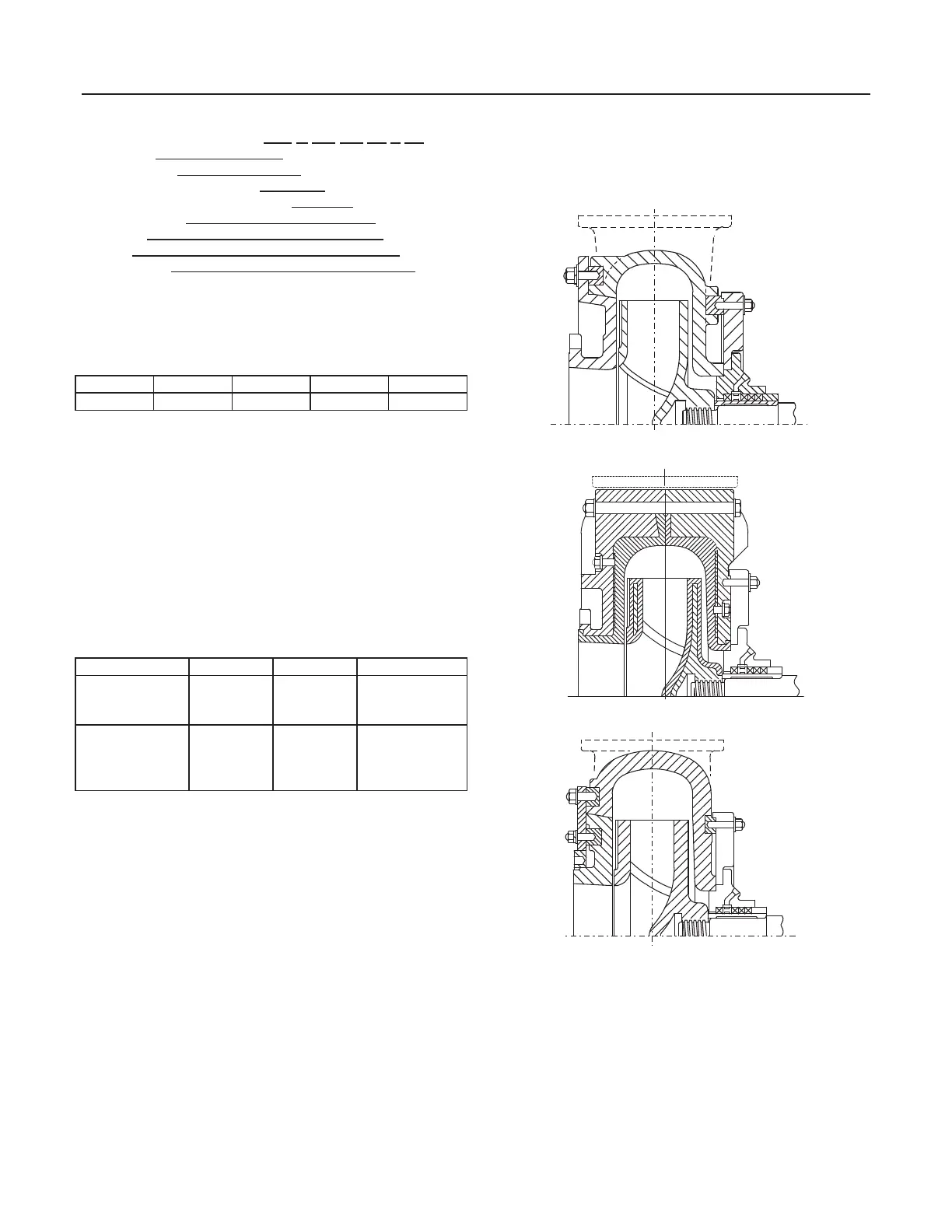

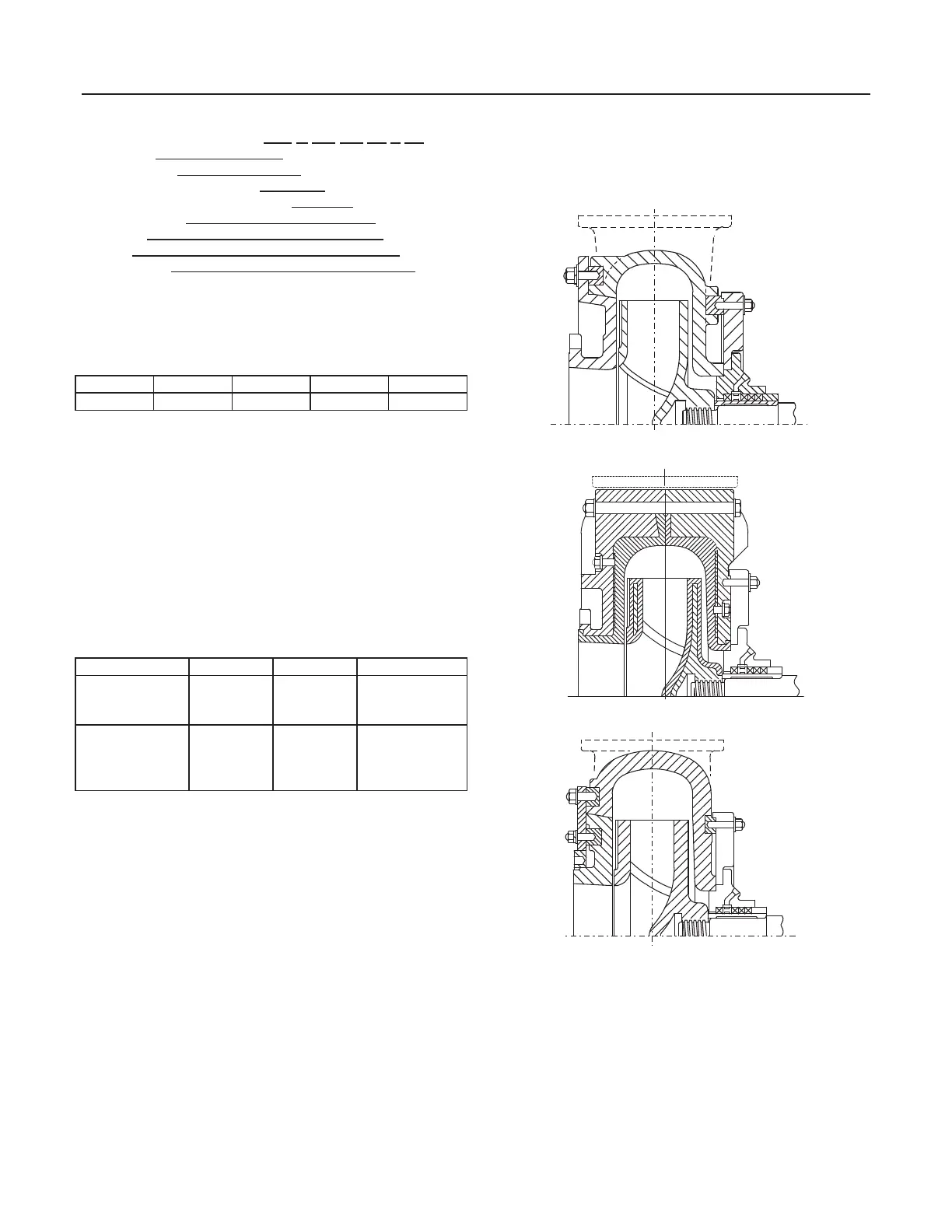

Horizontal, end suction, modified volute casing pump with

three-vane impeller for large solids passage. Available in

interchangeable elastomer, metal and extra-heavy designs.

4.3.1 Pump Casing

Three standard configurations are available:

1 Hard Metal. Single-wall casing, impeller and suction

liner of high-chrome white iron. Suitable for high-discharge

head, all particle sizes up to maximum sphere passage and

mildly corrosive slurries. Custom materials available for

highly corrosive slurries.

2 Elastomer Lined. Radially split construction with ductile

iron outer casing and molded-elastomer inner liners.

Impeller of high chrome white iron or polyurethane. For

moderate discharge head, fine to medium particles and

highly corrosive slurries.

3 Extra Heavy Hard Metal. Similar to hard metal version,

but with heavier sections and hydraulics suited to the most

severe slurry duties. Two-stage pressure capability.

Available in sizes LCC 150 - 500 and above.

All casings carry 125 pound, ANSI flange bolting patterns.

Adapters for conversion to DIN flanges are available.

Figure 4.3-1 LCC Hard Metal Wet End

Figure 4.3-2 LCC Elastomer-Lined Wet End

Figure 4.3-3 LCC Extra Heavy Hard Metal Wet End

4.3.2 Impeller Form

All standard impellers are 3 vane, double shrouded designs

as seen in figures 4.3-1 through 4.3-3. Open-shrouded and

alternate vane number designs are available in some sizes.

4.3.3 Shaft Seal

All standard pumps use replaceable gland packing in a

stuffing box with connections for flush water or sealing liquid.

Options include throat bushing, slurry duty mechanical seals

or expeller with grease lubricated gland packing.

1 2 3 4 5

35 mm 50 mm 70 mm 100 mm 125 mm

Loading...

Loading...