KWP

3.1.2 Shaft seal

The shaft is sealed at its exit through the casings by soft packed

stuffing boxes or by mechanical seals. Mechanical seals can

be fitted in lieu of soft packing (or viceversa) at any time during

the service life of the pump with a minimum of machining of

the stuffing box housing. Regarding machining details refer to

the pump manufacturer.

3.1.2.1 Stuffing box

Soft packed stuffing boxes reduce the flow of leakage liquid at

the clearing gap between casing and shaft protection sleeve

when the pressure inside the pump is higher than atmospheric.

Conversely, on pumps which operate on suction lift, the soft-

packed stuffing box prevents the ingress of air into the pump.

Sealing is effected by means of soft packing arranged in a

number of rings in the annular space between the stuffing box

housing (151) and the shaft protection sleeve (524) and lightly

compressed by the stuffing box gland (452)

3.1.2.2 Packing the stuffing box

The stuffing box will only be able to perform its vital function

satisfactorily on condition that it is carefully packed and

properly maintained as prescribed.

Before packing, thoroughly clean stuffing box gland (452),

packing compartment and shaft protection sleeve (524)

To cut the packing rings to correct length, use a suitable

wooden cutting jig (we can supply same on request), to ensure

that the packing rings are of the correct length and that their

ringbutts come into correct contact with one another (See Fig.

7)

Fig. no. 7 : Cutting the packing rings to length

If the packing rings are either too long or too short, the stuffing

box will not be able to perform its function properly. In the

case of asbestos-graphite packing material, the rubbing faces

of the individual rings should be lightly coated with

molybdenum disulphide before insertion in the packing

compartment. The first ring is then inserted and pushed home

into the compartment with the aid of the stuffing box gland.

The following packing rings are then inserted into the packing

compartment one by one, making sure that the butt joint of

each ring is offset 90 approx. in relation to the butt joint of the

preceding ring; the individual rings are pushed home into the

packing compartment with the aid of the stuffing box gland.

The packing rings should only be pressed lightly against one

another. They should be inserted in the packing compartment

in such a way that the a clear gap of 6 to 8 mm is left at the

outer end of the compartment for the positive guidance of the

stuffing pressure ring.

The inserted packing rings should then be compressed

moderately with the aid of the stuffing box gland (452) and of

the nuts. Then the nuts should be slackened again by one to

two complete turns, and thereafter tightened lightly by hand.

The correct and even seating of the stuffing box gland (452)

should be checked when the pump is subjected to suction

pressure, by inserting a feeler gauge between the gland (452)

and the shaft protection sleeve. (524)

In the case of the special stuffing boxes, a lantern ring is also

inserted in the packing compartment, viz, at the centre of the

compartment (between the packing rings). In these cases, an

information plate is affixed to the stuffing box housing, showing

the position of the lantern ring. The ring must register beneath

the drilled hole in the stuffing box housing, to enable the sealing

or flushing liquid to flow through the hole and the ring. The

sealing or flushing liquid pressure should be 1 to 4 bar above

the pressure reigning in the packing compartment of the

stuffing box.

The packing of the stuffing boxes should be carried out with

great care, to avoid an excessively high radial pressing force

of the packing rings against the shaft protection sleeve, which

might damage the latter. If the shaft protection sleeve is scored

or grooved, even a new packing can not be expected to last

very long in service.

A newly packed stuffing box should leak profusely at first. If

this leakage does not cease of its own accord after a relatively

short period of operation, the nuts on the gland should be

tightened slowly and evenly while the pump is running, until

the stuffing box only drips slightly. Make sure the stuffing box

glands (452) are tightened evenly and not askew, as otherwise

the shaft protection sleeves (524) might be damaged.

If the newly packed stuffing boxes start to smoke when the

pump is started up for the first time, the pump should be

switched off. If the smoking persists after the pump has been

started up again and operated several times in succession,

the nuts on the gland should be slackened slightly, or the

stuffing box should be inspected if necessary.

3.1.2.3 Packing material

When selecting the packing material, make sure it is

compatible with the fluid pumped (consult the manufacturer

in case of doubt)

Packing material which has been kept in store for a certain

period has a longer service life than packing material fresh

from the packing manufacturer.

Significance of the numbers punched on this instruction plate

is as follows

In this case 3

The no. of packing rings punched for the different packing

arrangements are as follows

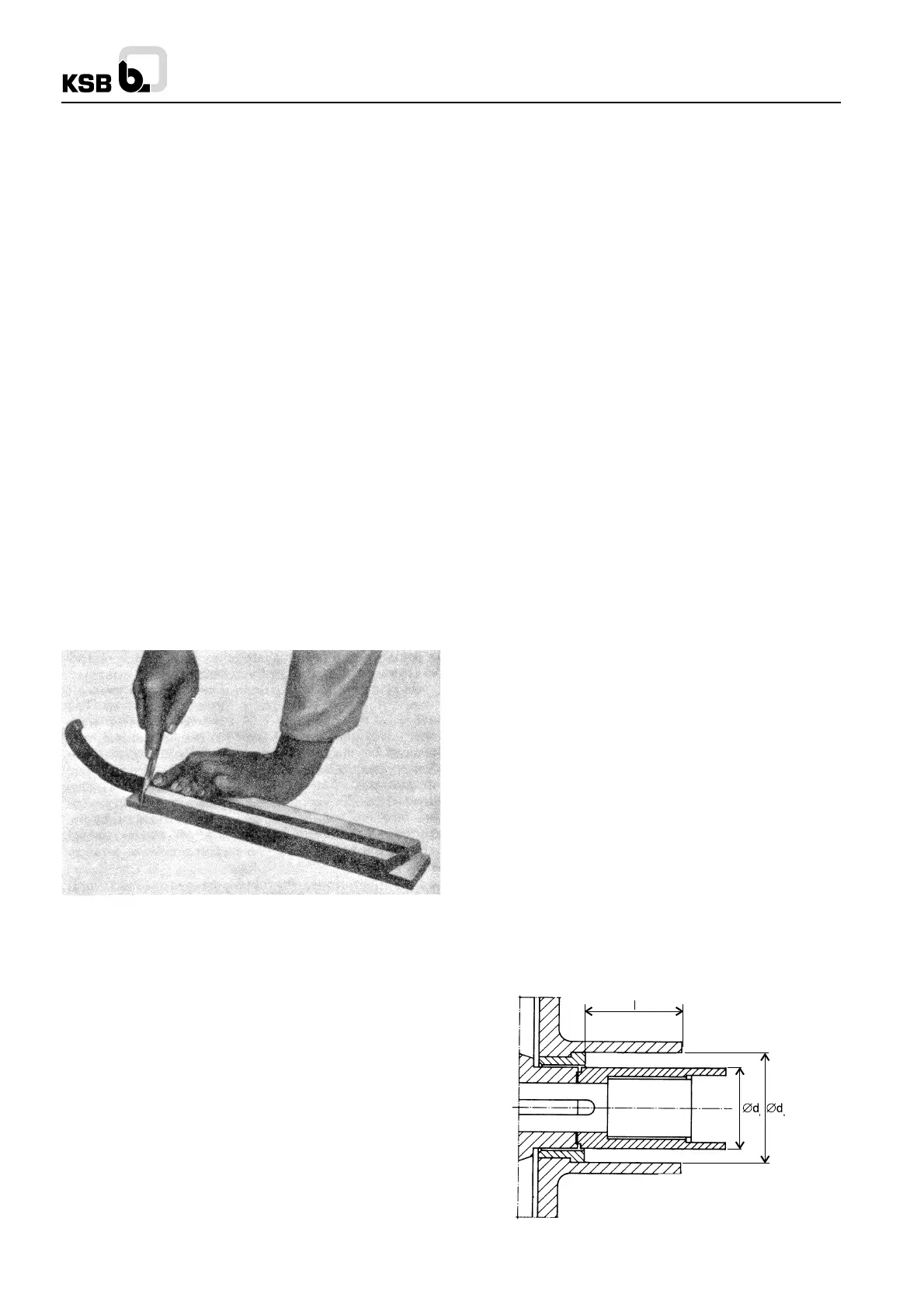

3.1.2.4 Dimensions of the packing compartment

Fig. no. 8 : Stuffing box compartment

3

Loading...

Loading...