KWP

7. Unscrew the impeller screw 906 (right hand thread),

remove the O Ring 412.03. Pull off the impeller with a special

puller type device of KSB make as shown in fig.9. Remove

the key.

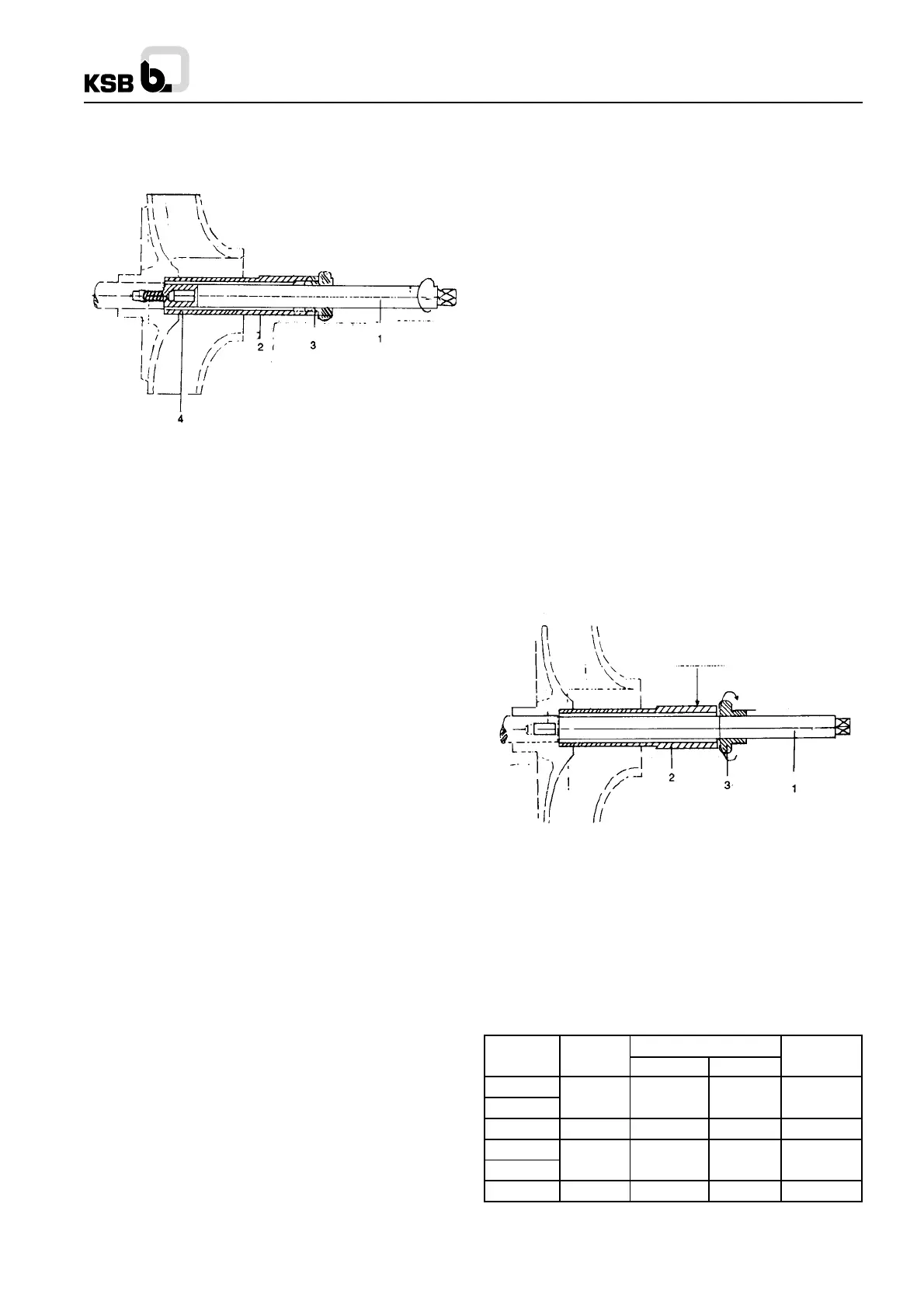

1. Spindle

2. Puller/Pusher bolt

3. Nut

4. Extension piece

Fig no. 9 Arrangement of Puller

8. Dismantling the shaft seal : Remove the stuffing box gland

452 after unscrewing the hexagonal nuts 920.2. Strip off the

stuffing box pressure ring 454, the packing rings 461, lantern

ring 458 and the packing rings located behind the lantern ring.

9. Remove pressure cover 163 from the bearing bracket

lantern.

10. Unscrew nuts 920.4 on the connecting studs of the flange

between bearing bracket lantern and bearing bracket , and

remove the bearing bracket lantern 344.

11. Pull shaft protection sleeve 524.01 together with Flat

Gasket 400.04 off the shaft.

Force open the splash ring 524.01 by splaying it with a wedge

or a screw driver and then pull it off the shaft.

12. Pull off pump half-coupling from stub shaft with the aid

of a puller device.

13. Dismantle pump end and motor end bearing cover 360.1

and 360.2 by unscrewing the screws 914.2/3.

14. Carefully drive out the shaft 210 together with bearings

321.1/2 or 322 towards the motor end.

15. If it is necessary to renew the antifriction bearings 321.1/

2 or 322, they should be warmed up by means of a welding

torch or a blow-lamp before pulling them off the shaft, and

the shaft itself should be kept as cool as possible.

16.Examine wear plate 135.01 for signs of wear and if

necessary remove them from pump casing.

For dismantling the wear plate, remove hex head bolt 901.03

together with gasket 411.13. Take care not to damage gasket

411.1 and O ring 412.05

17. Clean all components and inspect them for signs of wear.

Touch up any damaged parts or replace them by new ones.

5.1.3. Reassembly

Reassembly proceeds in reverse sequence to dismantling. It

should be undertaken with the greatest care, and with the aid

of the relevant sectional drawing, to ensure trouble-free

running of the pump.

Carefully examine all seals during reassembly O-rings, radial

seal rings and gaskets should be examined for any sign of

damage and if necessary replaced by new ones. Flat gaskets

should in principle always be replaced by new ones. The

antifriction bearings, shaft bearing brackets and stuffing box

components should be thoroughly cleaned in petrol or benzol.

Coat the fits of the individual components with graphite or a

similar lubricant before reassembly, this also applies to the

screw threads.

The following points should be carefully observed.

1. Standard bearing arrangement

If new bearings are fitted, make sure that they are of the correct

size and type (see 4.2). Heat bearings in an oil bath to

80

0

C.(175 o F) approx. before slipping them onto the cleaned

shaft, until they abut against the shaft shoulders. Replace shaft

carefully in the bearing bracket.

2. When mounting the bearing covers 360.01/.02 take care not

to damage the gaskets 400.01/.02 and oil seals 421.01/.02.

Press neck ring 456.01 into the pressure cover 163. In the

case of the packing arrangement illustrated in For packing

the stuffing box refer to point No. 3.1.2.6.

For packing the stuffing box refer point No. 3.1.2.3.

CAUTION :

The stuffing box should drip slightly when the pump is running.

Any sealing and flushing liquid connections on your pumps

should be checked from time to time for unimpeded flow of

the fluid. After the gland has been tightened repeatedly in the

course of operation until it can be tightened no further, the

pump should be repacked completely with new packing.

3. Carefully insert the impeller gasket 400.04 and make sure

that all joints and sealing faces are perfectly clean.

The impeller should be pressed onto the shaft only with the

help of a pusher device supplied by us. Hammering should

never be resorted to. See Fig. 16.

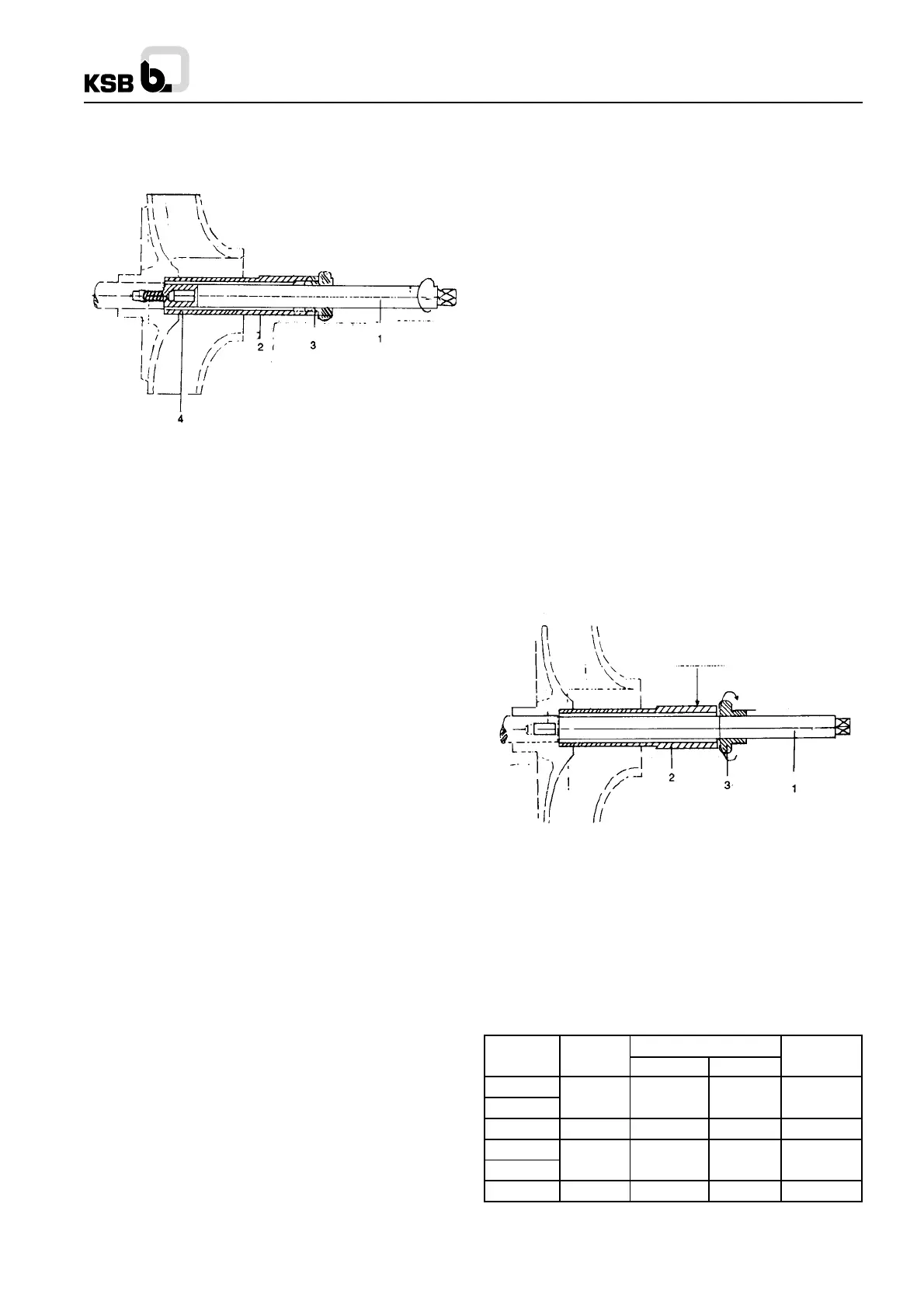

1. Spindle

2. Puller/pusher bolt

3. Nut

Fig. no. 10 : Arrangement of Pusher.

4. After assembly in the pump casing which has remained in

situ in the piping, the coupling alignment should be checked

(see item 1.3)

5. Fill in oil in accordance with item 3.1.

5.2 Bearings

The pump is fitted with antifriction bearings as follows

A. Standard bearing bracket

Table 3

Pump side Drive side

65-200

80-250

65-315 P45-120 6409 6409 500

100-400

150-315

125-500 P65-160d NU 413 6413 1800

150064116411P55-140

Pump size

il fill (cm³)

approx.

Bearing

bracket

P35/80 6307 6307 500

Bearings

6

Loading...

Loading...