WK

9. Piping

The main piping should be connected to the pump without

transmitting any stresses or strains onto the latter. Any

appreciable piping forces which are transmited to the base-

plate via the PUMP can detrimentally affect the alignment and

the running of the pump. Such forces should therefore be kept

to a minimum at all costs.

9.1 Suction Lift Line and Positive Suction Head Line

The pipe line connected to the suction casing (106) is called

either a suction lift line or a (positive) suction head line,

depending on whether the pressure at the pump inlet is below

or above atmospheric pressure. This line should be kept as

short as possible. (see Figs. 43 and 44)

Suction lift lines should rise all the way towards the pump,

they should also be absolutely leak tight and be laid in such a

way as to prevent the formation of air pockets at any point.

(see Fig. 43).

Fig. 43 Suction lift line

The nominal size of the pump suction flange is no accurate

guide to the size of the suction lift line. The latter should be

sized, as a first approximation to give a velocity of 2m/sec.

approx. In principle, every pump should be equipped with its

own individual suction lift line. If this is not feasible for particular

reasons, the common suction lift line should be sized for a s

low a velocity as possible and preferably for a constant velocity

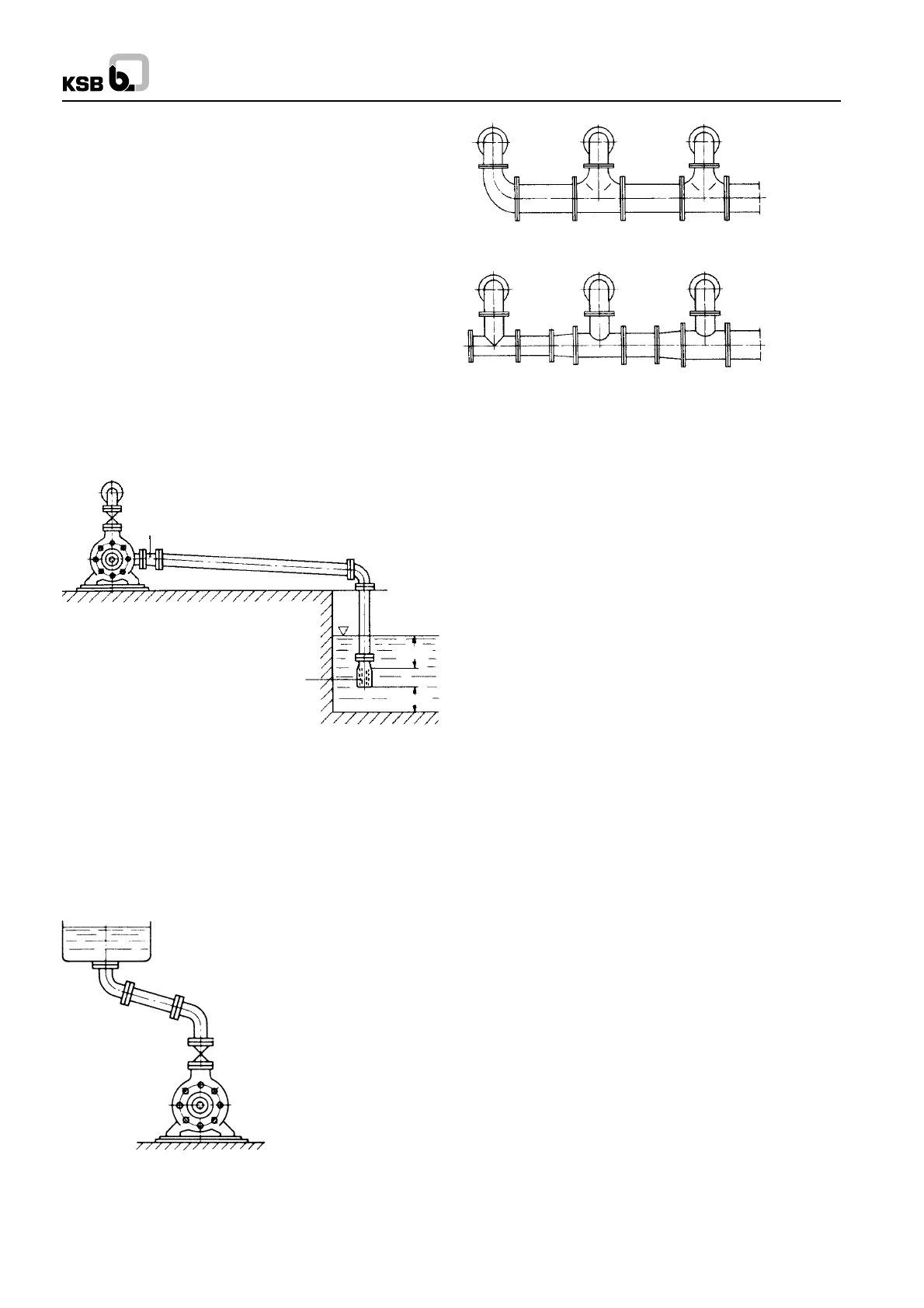

right up to the last pump on the line (see Fig. 45).

In addition, pumps connected to a common suction lift line

should be equipped with VSM stuffing boxes.

If the suction lift line is buried, it should be hydrostatically tested

at 3 to 4 bar before burial.

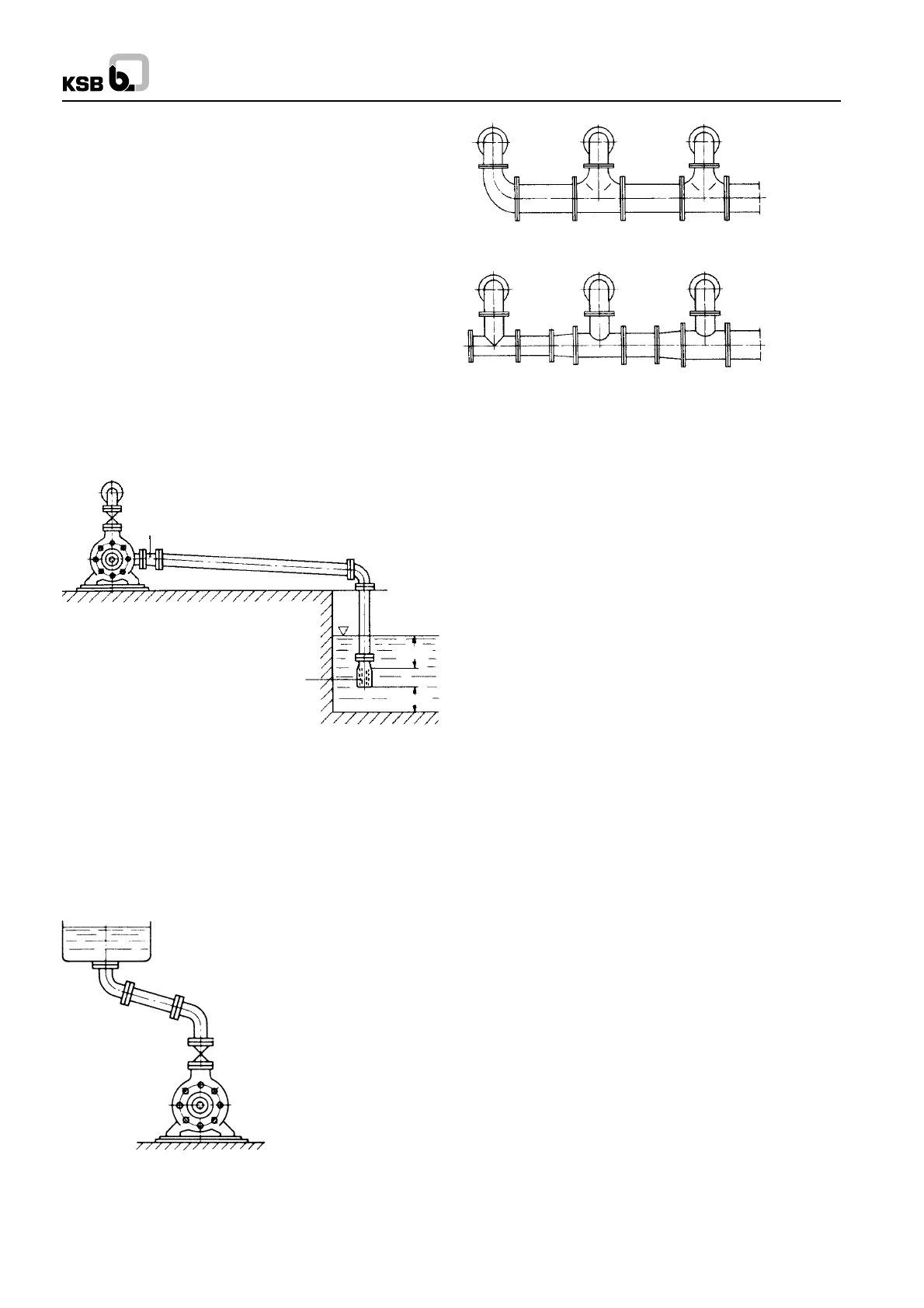

The same remarks as above apply to the nature and laying of

(positive) suction head lines. Horizontal lenngths of suction

head lines should however be laid with a slightly rising slope

towards the suction vessel. If it is not feasible to avoid apexes

in the suction head line, each apex should be equipped with a

vent cock. It is also advisable to avoid any appreciable length

of horizontal suction head line laid close beneath the suction

vessel because of the danger of evaporation (see Fig. 44).

9.1.1 Strainers in Suction Head Line/Suction Lift Line

Before a new pumping installation is commissioned, all the

vessels, piping and connections should be thoroughly cleaned,

flushed through and blown though. It often happens that welding

beads, pipe scal and other dirt only become detached from

inside the piping after a considerable period of service; they

must therefore be prevented from penetrating inside the pump

by the provision of a strainer in the suction head or suction lift

line. This strainer should have a free area of holes equal to 3

times the pipe cross section area approx., in order to avoid an

excessive pressure drop when foreign bodies tend to clog the

strainer.

Conical (hat shaped) strainers have given good results in

service (see DIN 4189), they should have a woven wire insert

of corrosion-resistant material with a 1.0 mm. mesh width of

0.5 mm. diameter wire. The fine strainer should precede the

coarse strainer in respect of direction of flow of the fluid. During

the initial period of commissioning, the suction pressure should

be kept under frequent observation. If the NPSH available is

found to decrease, this may be due to clogged strainers (the

pressure drop acros the strainer should be measured with the

aid of a differential pressure gauge). The strainers should then

be cleaned. (see Figs. 46 and 47).

Unless anything to the contrary has been specified, the max.

permissible pressure drop across the strainer should not

exceed 3 meters.

Eccentric reducer (fitted belly down)

Suction strainer basket

>0.5m

>0.5m

Fig. 44 Suction head line

Fig. 45 Common suction lift line for several pumps

Correct

Wrong

11

Loading...

Loading...