WK

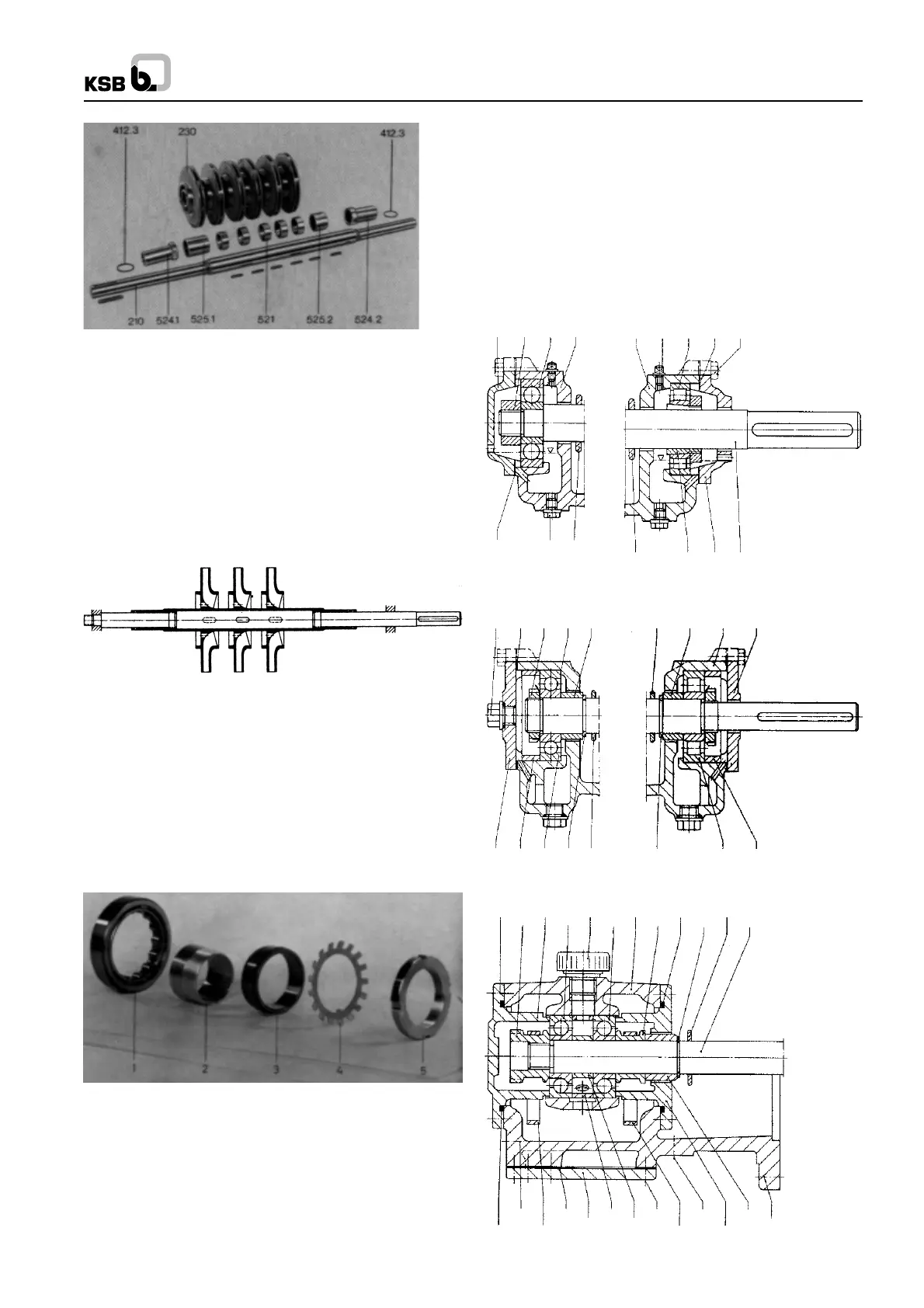

Fig. 4 Dismantled rotor

In order to balance the axial thrust, throttling passages are

arranged at the impeller necks at the suction and discharge

end of each impeller, and additional balancing holes are

provided in the impeller necks at the discharge end

(See Fig. 5).

A fixed bearing absorbs the residual axial thrust generated

and also locates the rotor in the axial position; in the standard

bearing construction, this bearing consists of a deep groove

ball bearing (321) and in the pump construction with heavy

duty bearing bracket, it consists of two angular contact ball

bearings (320).

1.3 Bearing Arrangement

WK pumps are fitted with different types of beaings and bearing

housing, depending on the differential head (generated

pressure) of the pump. In the case of low differential heads,

the standard bearing construction is provided. In the case of

higher total heads, the heavy duty bearing construction is

provided to absorb the increased residual thrust.

The pump manufacturer decides which type of bearing

arrangement shall be provided.

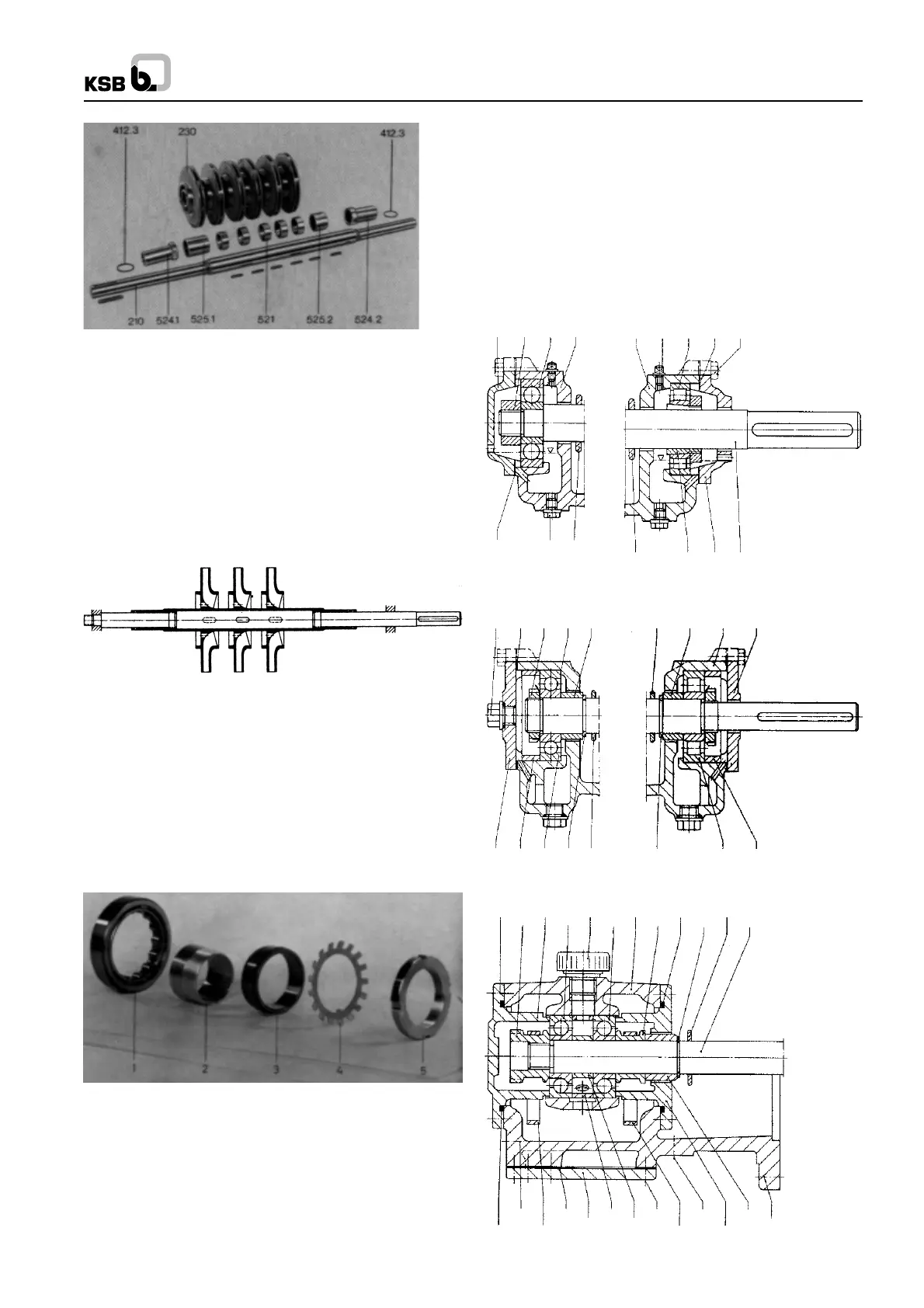

Fig. 6 Individual bearing components (drive end)

Part 1 = Outer race with cage and rollers

Part 2 = Adaptor Sleeve

Part 3 = Inner bearing race

Part 4 = Locking Washer

Part 5 = Withdrawal Nut

Standard Bearing Construction :

Drive end : 1 Cylindrical roller bearing in accordance with DIN

5412 (see Fig. 6) with adaptor sleeve in accordance with DIN

5412 and standard bearing bracket (No adaptor sleeve

provided on pump size 150).

End side : 1 deep groove ball bearing in accordance with DIN

625 and standard bearing housing (see Figs. 7 and 8).

Heavy Duty Bearing Construction :

Drive end : Same as atandard bearing construction. End

side : 2 matched angular contact ball bearings in accordance

with DIN 628; X arrangement and heavy duty bearing bracket

(see Fig. 9).

Fig. 9 Bearing construction with heavy duty bearing

bracket size 150.

Fig. 7 Bearing construction, size 40 to 125

361 920.4 321 350 350 731.2 322 400.4 901.2

400.4

903.4

(13B)

507

507 52-1 360 210

Fig. 8 Bearing construction, size 150

903.12

400.4 920.4 350 525.4

507 525.4 350 360

361 543 321 932 507 932 322 543

Drive end

Fig. 5 Rotor

901.3 361 913 350.2 412.7 507

210

932508320320923

412.7 644 644 360.2

902.3

525.5

720.3

(

8B

)

901.4

525.8160

543400.5

903.5

(

13B

)

2

Loading...

Loading...