WK

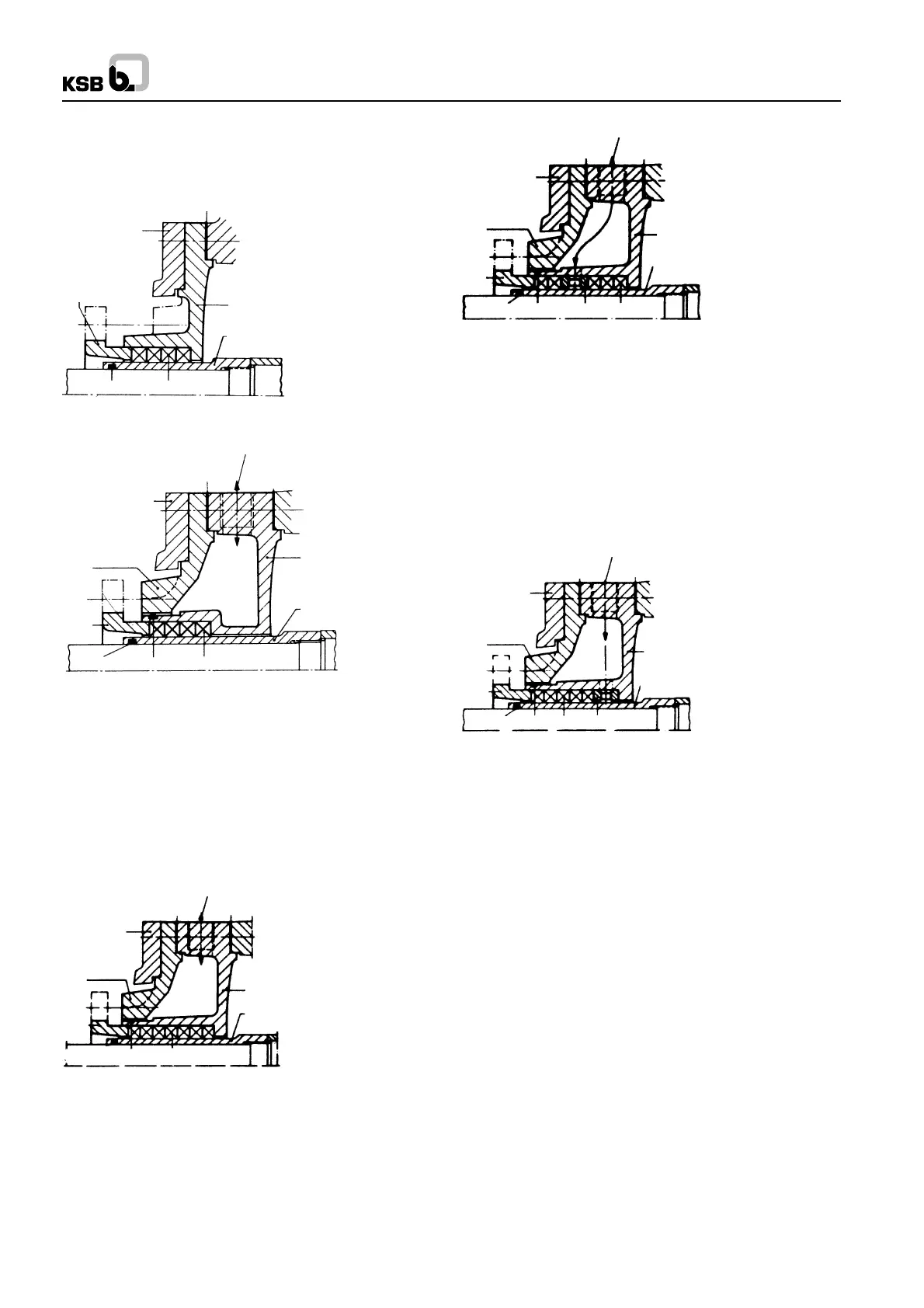

Soft-packed stuffing box, ‘‘Standard’’ (N) construction.

Standard construction with 4 packing rings (461.1) used for

temperatures of the fluid pumped up to 105

0

C. The stuffing

box compartment cannot be cooled.

Soft-packed stuffing box, ‘‘Hot Water’’ (HW) construction.

Construction with 4 packing rings (461.1) and cooling of the

stuffing box compartment. Used for temperatures of the fluid

pumped in excess of 105

0

C up to 230

0

C max.

Special stuffing box, ‘‘Extra-deep’’ (V) construction.

Construction with 7 packing rings (461.1) and cooling of the

stuffing box compartment, used mainly in process industry

applications.

Special stuffing box, ‘‘VSM’’ Constructed

VSM is the abbreviation (in German) of ‘‘Extra deep with lantern

ring at the centre’’.

Construction with 5 packing rings (461.1) and one seal case

ring (458) arranged at the centre of the packing compartment;

used mainly for operation under vacuum or suction lift, and

where malodorous fluids are pumped. For operation under

vacuum, the lantern ring (458) is fed with a sealing liquid, and

it prevents the ingress of air into the pump.

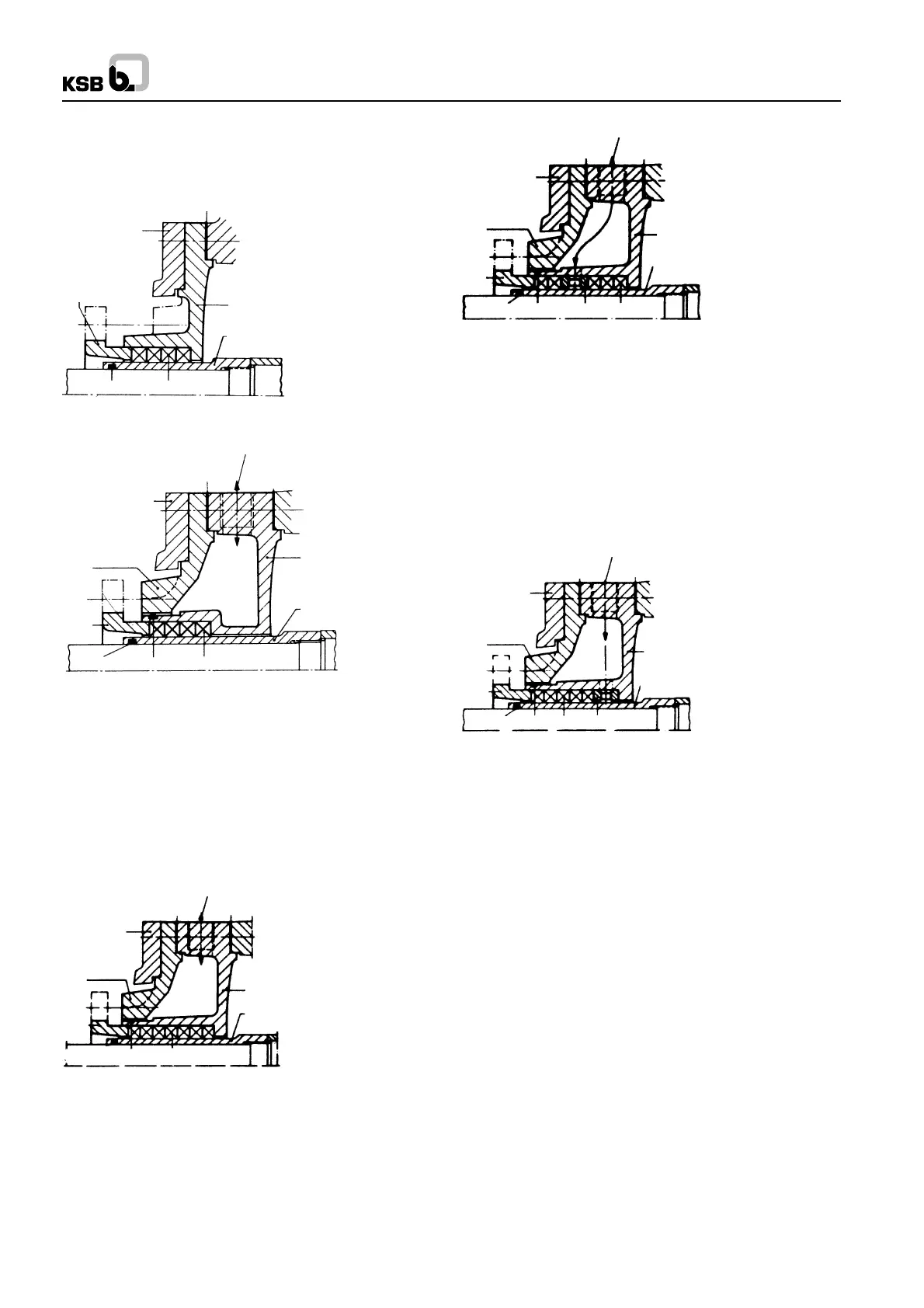

Special stuffing box, ‘‘VSH’’ constructed.

VSH is the abbreviation (in German) for ‘‘Extra deep with seal

cage ring at the bottom of the box’’. The construction with 5

packing rings (461.1) and a seal cage ring (458) arranged at

the bottom of the packing compartment is used where fluids

containing abrasive particles are pumped. The flushing liquid,

which should be fed through the cage ring (458) at a pressure

of at least 1 to 4 bar (max.) above the suction pressure,

penetrates inside the pump and protects the stuffing box

packing (461.1) against abrasive substances.

1.5.1.1 Cooling Liquid for Stuffing Boxes

Treated cooling water which does not tend to precipitate salts

causing hardness out of solution should be used as cooling

liquid. The cooling water should be allowed to flow out freely

and visibly, so that it can be checked at any time in respect of

rate of flow and temperature. The temperature differential

between cooling water inlet and outlet should not exceed 10

0

C.

The max. permissible cooling water outlet temperature should

not exceed 50

0

C. The cooling water pressure should be situated

between 1 bar min. and 10 bar max.

An isolating valve should be incorporated in the cooling water

supply line, to enable the rate of flow of cooling water to be

adjusted, and the supply of cooling water to be turned off when

the pump is shut down. The cooling water should only be turned

off after the temperature of the fluid inside the pump has

dropped to below 80

0

C.

1.5.1.2 Packing the Stuffing Boxes

Caution : The pump is despatched from our works with the

stuffing boxes unpacked. An adequate quantity of packing

material is supplied loose with the pump. The stuffing box will

only be able to perform its vital function satisfactorily on

condition that it is carefully packed and properly maintained

as prescribed.

Before packing, thoroughly clean stuffing box gland (452),

packing compartment and shaft protection sleeve (524.1/.2).

Fig. 15 ‘‘Standard’’ (N) construction stuffing box

412.3

461.1

452

350

400.3

451

524.2

(524.1)

Fig. 16 ‘‘Hot Water’’ (HW) construction stuffing box

412.3 412.4 461.1

452

165

350

400.3

7A/7E

400.3

451

524.2

(524.1)

Fig. 17 Special soft packed stuffing box ‘‘Extra deep’’ (V)

412.3

412.4 461.1

452

165

350

400.3

7A/7E

400.3

451

524.2

(524.1)

Fig. 18 Special stuffing box VSM

Fluids pumped :

Operation under vacuum

or pumping of malodorous

fluids (ammonia and

solvents).

Sealing liquid consumption

1 to 3 litres/hours approx.

412.3 412.4 461.1

452

165

350

400.3

10A/10E

400.3

451

524.2

(524.1)

458

Fig. 19 Special stuffing box VSH.

Fluids :

Products containing abrasive

particles, which must be kept

away from the stuffing box

packing, so as not to erode

the latter (oils containing

diatomite (kieselguhr),

fractions from catalytic

cracking containing abrasive

catalyst particles).

Flushing liquid consumption

300 to 500 litres/hour approx.

412.3

412.4 461.1

452

165

350

400.3

11E

400.3

451

524.2

(524.1)

458

5

Loading...

Loading...