WK

bearing (321) by means of loan forcing screws until the

bearing housing and bearing can be pulled off the shaft

without effort.

5. Inspect condition of deep groove ball bearing (321) and if

necessary remove it form bearing housing (350).

6. Strip splash ring (507) off the shaft.

11.2.2.2 Heavy Duty Bearing Construction

1. Remove bearing end cover (361) including O-ring (412.7).

2. Unscrew shaft nut (923) and remove it from the shaft

together with lubricating ring (644).

3. Unscrew hex. nuts (920.2) from studs (920.3) in outlet

cover (107), in order to dismantle bearing housing (350).

4. Force off (with the aid of forcing screws) bearing housing

(350.2) together with angular contact ball bearing (320),

inner distance ring (525.8), outer distance ring (543), guide

bush (508) and lubrication ring (644), and pull the bearing

assembly off the shaft with the aid of an extractor.

5. Remove distance bush (525.5), circlip (932) and splash

ring (507) from the shaft.

6. Inspect condition of angular contact ball bearing (320)

and if necessary remove it form bearing housing (350.2).

11.3 Removing the Shaft Seal

11.3.1 Soft-packed Stuffing Box Construction

1. Pull stuffing box gland (452) off the shaft.

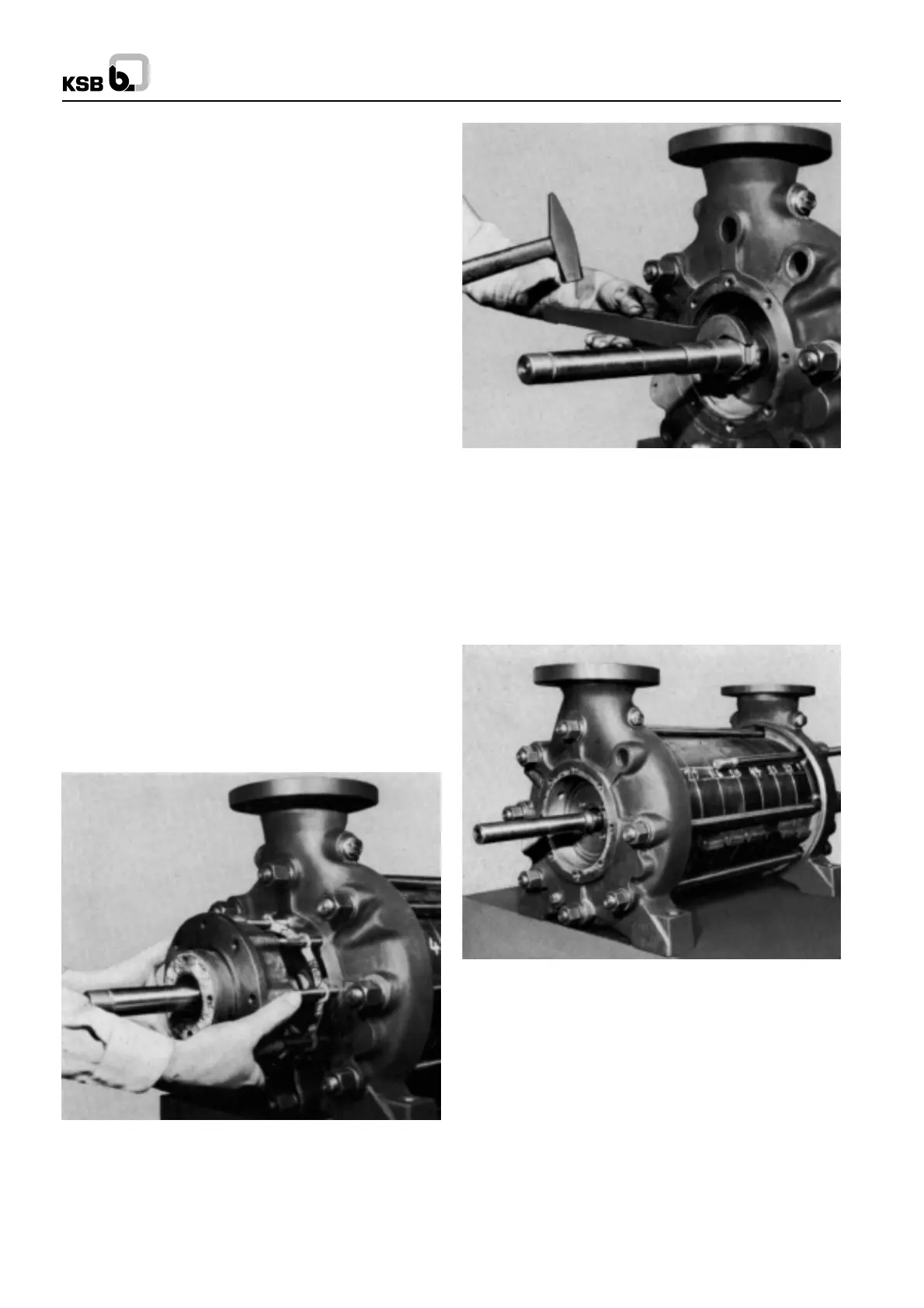

2. Force off and remove stuffing box housing (451). On

pumps equipped with cooled stuffing boxes, force off and

remove the stuffing box housing (451) including cooling

cover (165) (see Fig. 63).

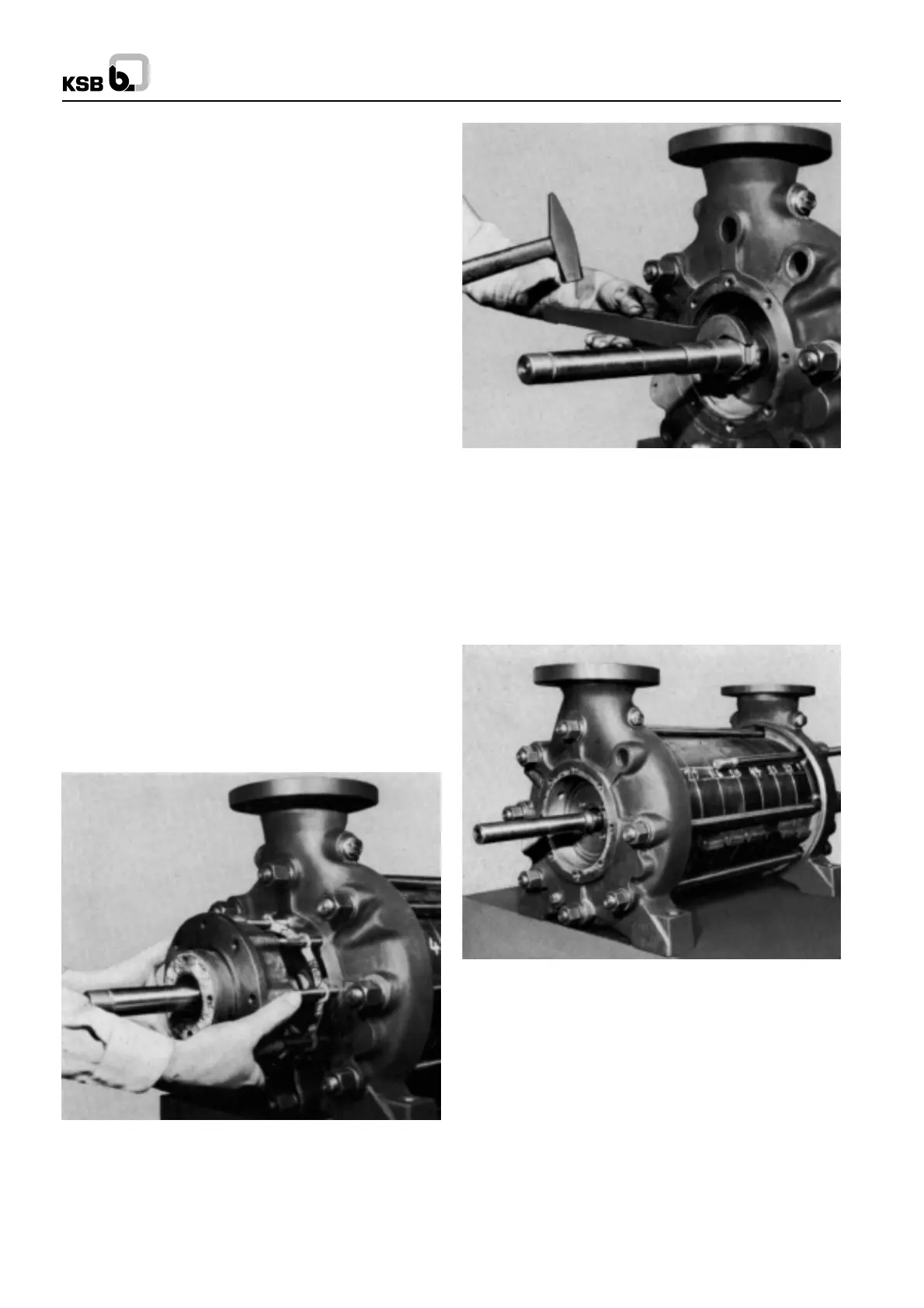

3. Slacken shaft protection sleeve (524.2) and remove it from

shaft (210) (see Fig. 64)

Fig. 63 Removing the stuffing box housing (451)

11.4 Dismantling the Pump Body

1. The stage casings (108) should be numbered

consecutively in respect of their positions in relation to

one another before dismantling, to ensure that the suction

casing (106), the stage casing (108) and the discharge

casing (107) are all reassembled in the correct sequence

in relation to one another during reassembly (see Fig.

68).

Fig. 64 Slackening shaft protection sleeve (524.2)

2. Unscrew nuts (920.1) at discharge end or connection rods

(905) and pull the connection rods out of the suction and

discharge casing (see Fig. 68).

3. Underpin the pump at the stage casing (108) with wooden

blocks or an erection trestle, so as to free the component

which is to be dismanntled next.

4. Force discharge casing (107) together with diffuser/last

stage (171.2) off stage casing (108) and lift it off (see Fig.

69 and 70).

Fig. 68 Identification of casing components and removal of

tie rods

17

Loading...

Loading...