WK

A newly packed stuffing box should leak profusely at first. If

this leakage does not cease of its own accord after a relatively

short period of operation, the nuts on the gland should be

tightened slowly and evenly while the pump is running, until

the stuffing box only drips tightened evenly and not askew, as

otherwise the shaft protection sleeves (524.1/.2) might be

damaged (see Fig. 23).

The leakage rate in service of a soft-packed stuffing box should

amount to 3 to 5 litres/hours approx.

If the newly packed stuffing boxes start to smoke when the

pump is started up for the first time, the pump should be

switched off. If the smoking persists after the pump has been

started up again and operated several times in succession,

the nuts on the gland should be slackened slightly, or the stuffing

box should be inspected if necessary.

1.5.1.3 Packing Material

When selecting the packing material, make sure it is compatible

with the fluid pumped (consult the manufacturer in case of

doubt).

In steam generating plants, the asbestos-graphite packing

material specially developed for hot water service has given

good results. Packing material which has been dept in store

for a certain period has a longer service life than packing

material fresh from the packing manufacturer.

1.5.2 Mechanical Seals

Mechanical seals can be fitted as shaft seals in lieu of soft-

packed stuffing boxes. If it is intended to replace soft-packed

stuffing boxes by mechanical seals after the pump has been

in service for some time, it is necessary for the pump to be

equipped with stuffing box holdings (451) for ‘‘V’’ special stuffing

boxes. It is also necessary to re-machine two tapped holes in

the cooling cover (165) for the attachment of the seal cover

(471).

1.6 Coupling

The pump on connected to the driver by a flexible coupling.

Fig. 29 illustrated the type of coupling most frequently used.

Fig. 29 Flexible coupling

Spacer type couplings (see Figs. 30 and 31) enable inspections

and minor repairs (e.g. the fitting of new bearings or shaft

protecting sleeves) to be carried out without removing the driver.

Fig. 30 Spacer type flexible coupling

Fig. 31 Mounted spacer-type flexible coupling

2. Mode of Operation of Pump

The fluid flows through the suction casing towards the impeller

at a given pressure. Energy is transmitted to the fluid by the

impeller, which is fitted with vanes. From the impeller, the fluid

flows into the diffuser, where kinetic energy is converted into

potential energy, increasing the pressure rise still further.

The return guide vanes arranged on the discharge end cheek

of the diffuser (171.1) guide the fluid under hydraulically

favourable conditions towards the eye of the following stage

impeller (230). This process is repeated from one stage to the

next, and the pressure rise by the same amount in each stage,

viz. by the stage generated pressure. After leaving the final

stage diffuser (171.2), the fluid flows through the discharge

casing (107) into the discharge line connected to this casing.

The generated pressure creates an axial thrust on the pump

rotor of single and multistage centrifugal pumps. By the

provision of narrow throttling gap between the impeller necks

and the casing wearing rings at either side of each impeller,

equal size lateral impeller space, and therefore almost identical

pressure conditions are created at the suction and discharge

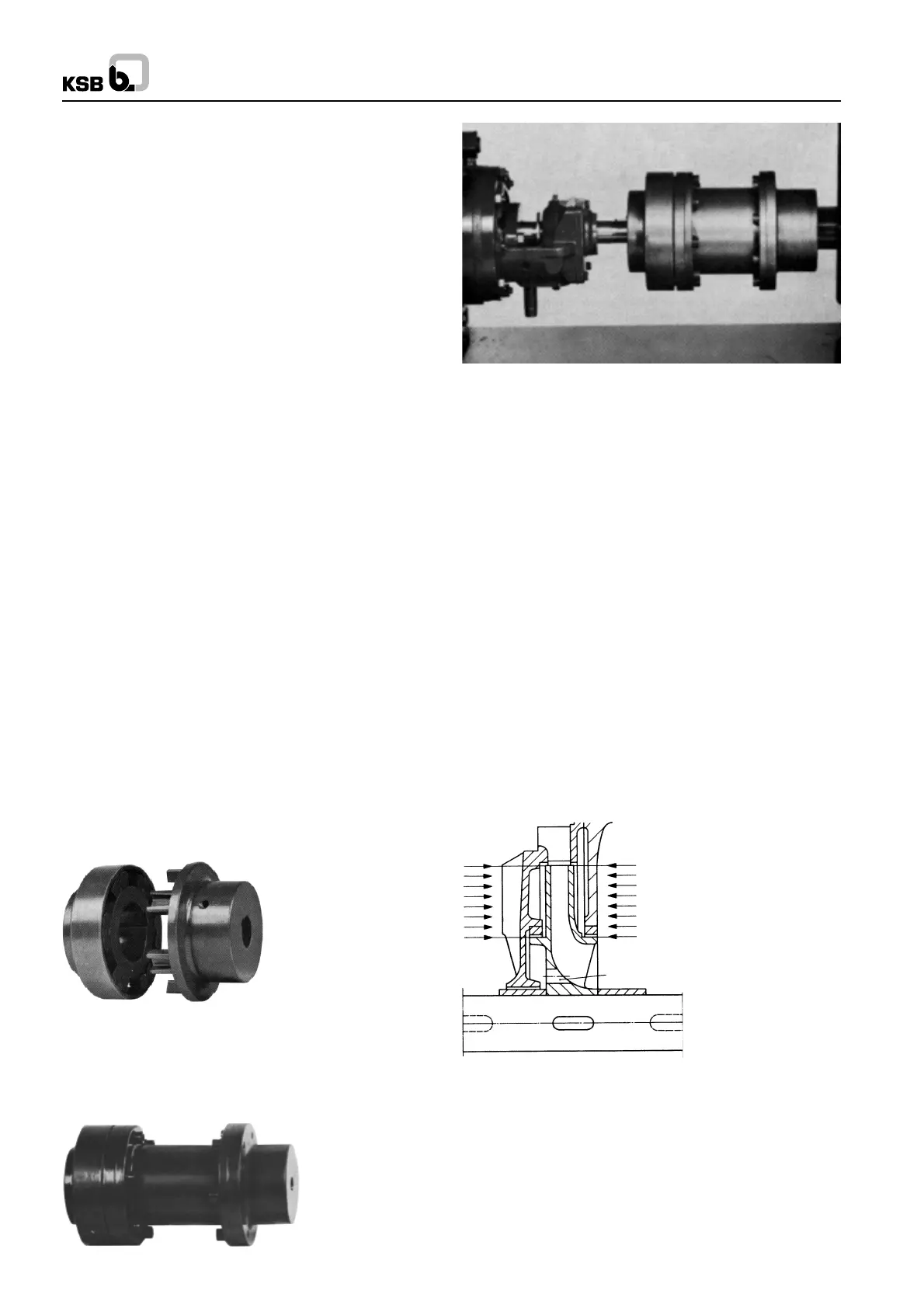

ends of each impeller (see Fig. 34).

The balance holes in the discharge side impeller cheeks ensure

a compensation of pressures between the suction and

discharge sides of the impellers in the region situated between

the impeller hub and the throttling gap, thus again preventing

the creation of any appreciable axial thrust in this region of the

impeller. Any residual axial thrust is absorbed by the fixed

bearing in the discharge end bearing housing. This fixed

bearing also locates the axial rotor position.

Fig. 34 Axial forces acting on impeller

Balance hole

7

Loading...

Loading...