WK

Oil Quality : Machinery oil possessing good air release

properties and corrosion prevention characteristics; kinematic

viscosity 36 cSt approx. = 4.8

0

E at 50

0

C; flash point 150

0

C

minimum; pour point lower than -20

0

C.

Lubrication times : First oil change after the first 500 hours of

operation, subsequent oil changes after every 3000 hours of

operation approx., but at least once a year.

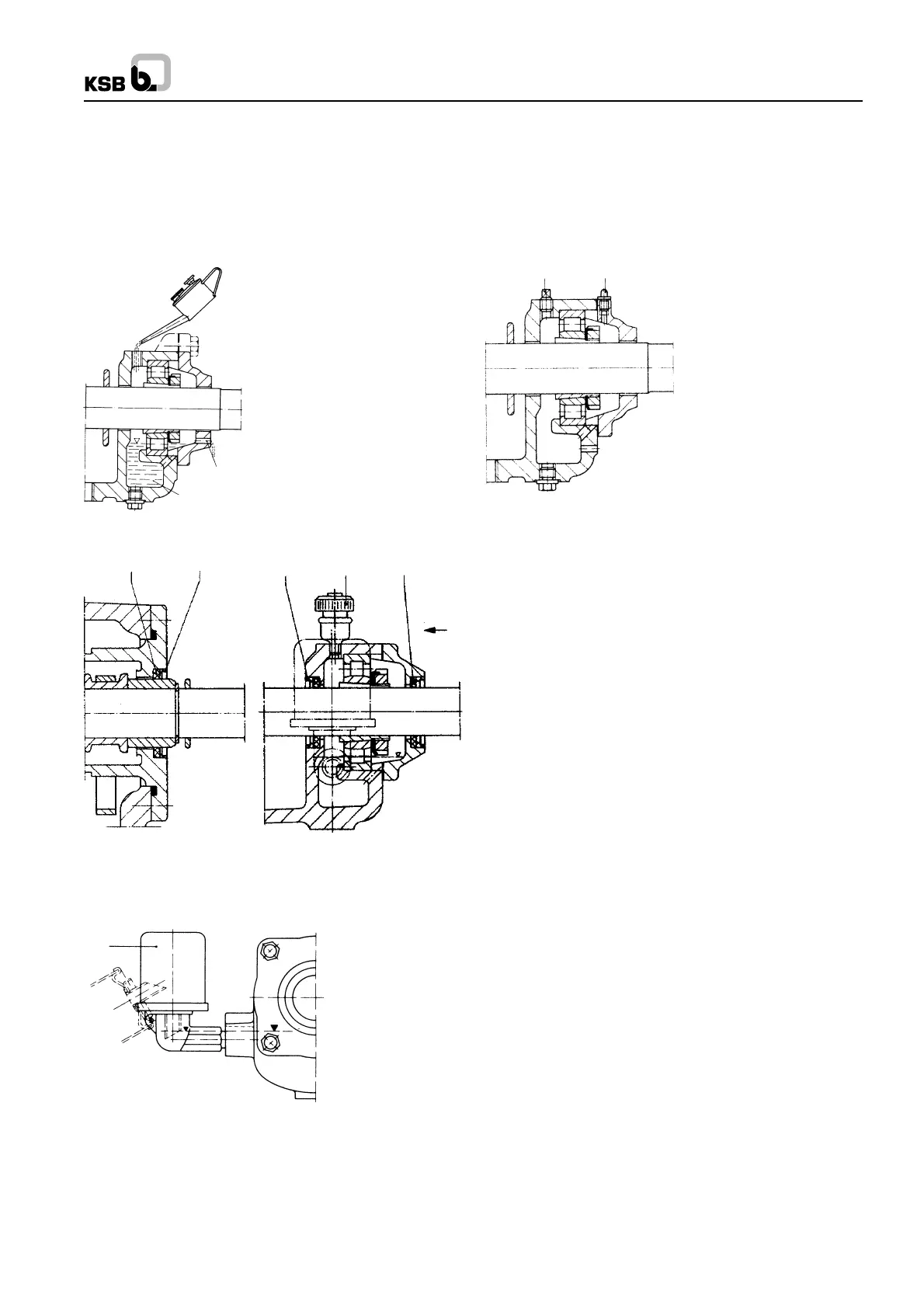

Fig. 11 Oil splash lubrication

Fig. 13 Constant level oiler viewed from X

Topping up of the oil fill at least once a month.

The bearing temperature may be allowed to rise up to 40

0

C

above room temperature, but should not exceed 80

0

C.

1.4.2 Grease Lubrication

(Cannot be provided on heavy duty bearing construction

pumps).

Portable (mobile) pumps, and pumps installed on board ship

have grease-lubricated bearings (See Fig. 14). Use a good

quality lithium soap ball and roller bearing grease, free of resin

and acid, and possessing rust preventive properties. The

grease should have a penetration number situated between 2

and 3, corresponding to a worked penetration situated between

2220 and 295 mm/10. Its drop point should be not less than

175

0

C.

The bearing temperature may be allowed to rise up to 40

0

C

above room temperature, but should not exceed 80

0

C. The

grease fill will last for 15000 hours of operation i.e., for 2 years

approx. If the operating conditions are arduous, the bearings

should be serviced once a year. A grease fill amounts to 10-20

grammes of grease, depending on the pump size. The pump

bearings are packed with grease at our Works before despatch.

1.5 Shaft Seal

The shaft is sealed at its exits through the casings by softpacked

stuffing boxes or by mechanical seals. If the pump is fitted with

special stuffing boxes, mechanical seals can be fitted in lieu of

soft packing (or vice versa) at any time during the service life

of the pump, with a minimum of machining of the cooling

compartment covers. On the other hand, the fitting of

mechanical seals to pumps equipped with standard or hot water

type soft-packed stuffing boxes necesitates the fitting of new

pump components. Particulars can be obtained from the pump

manufacturer.

1.5.1 Stuffing Boxes

Soft-packed stuffing boxes reduce the flow of leakage liquid at

the clearance gap between casing and shaft protection sleeve

when the pressure inside the pump is higher than atmospheric.

Conversely, on pumps which operate on suction lift, the soft-

packed stuffing box prevents the ingress of air into the pump.

Sealing is effected by means of soft packing (461.1) arranged

in a number of rings in the annular space between the stuffing

box housing (451) and the shaft protection sleeve (524.1/2)

and lightly compressed by the stuffing box gland (452).

Caution : On pumps which have a high discharge pressure,

the stuffing box at the discharge end is relieved of pressure,

via a balance liquid line, down to the suction pressure, provided

that the differential pressure across the pump exceeds 20 bar.

This ensures that the stuffing boxes at the suction and discharge

ends of the pump have the same admission pressure. This

arrangement applies to pump sizes 40 to 65 if the discharge

pressure exceeds 20 bar and to pump sizes 80 to 150 if the

discharge pressure exceeds 15 bar.

Single stage pumps require no special pressure relief even at

high discharge pressures. The pressure is relieved via the

balance holes in the impeller.

Overflow hole

Oil sump

Fig. 12 Construction with constant level oiler and sealing of

the bearing housing.

422.4

500.4

500.1 913 422.1

X

End side

(Heavy duty bring bracket)

Drive end

638

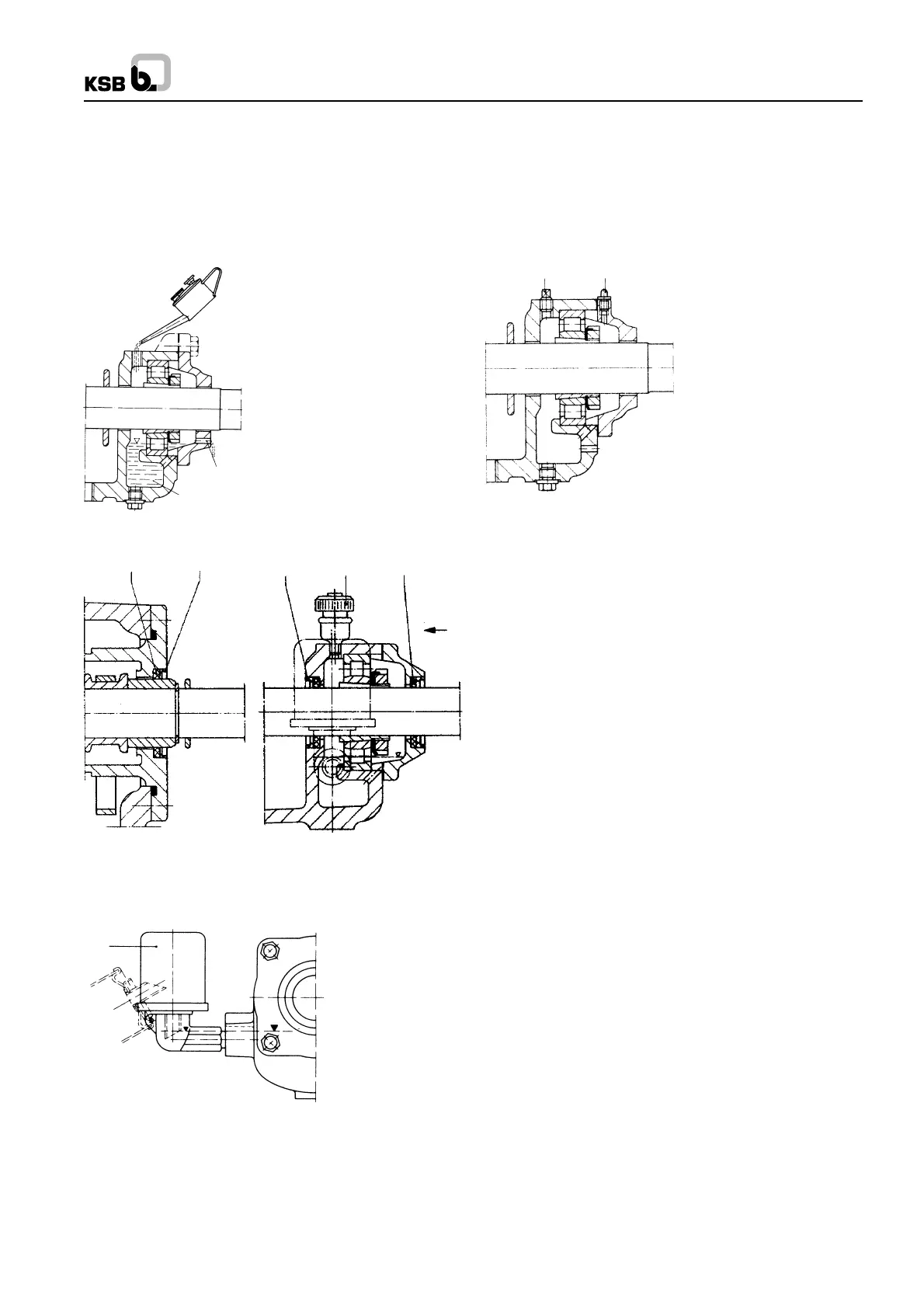

Fig. 14 Grease lubricated bearing construction

731.2 636

4

Loading...

Loading...