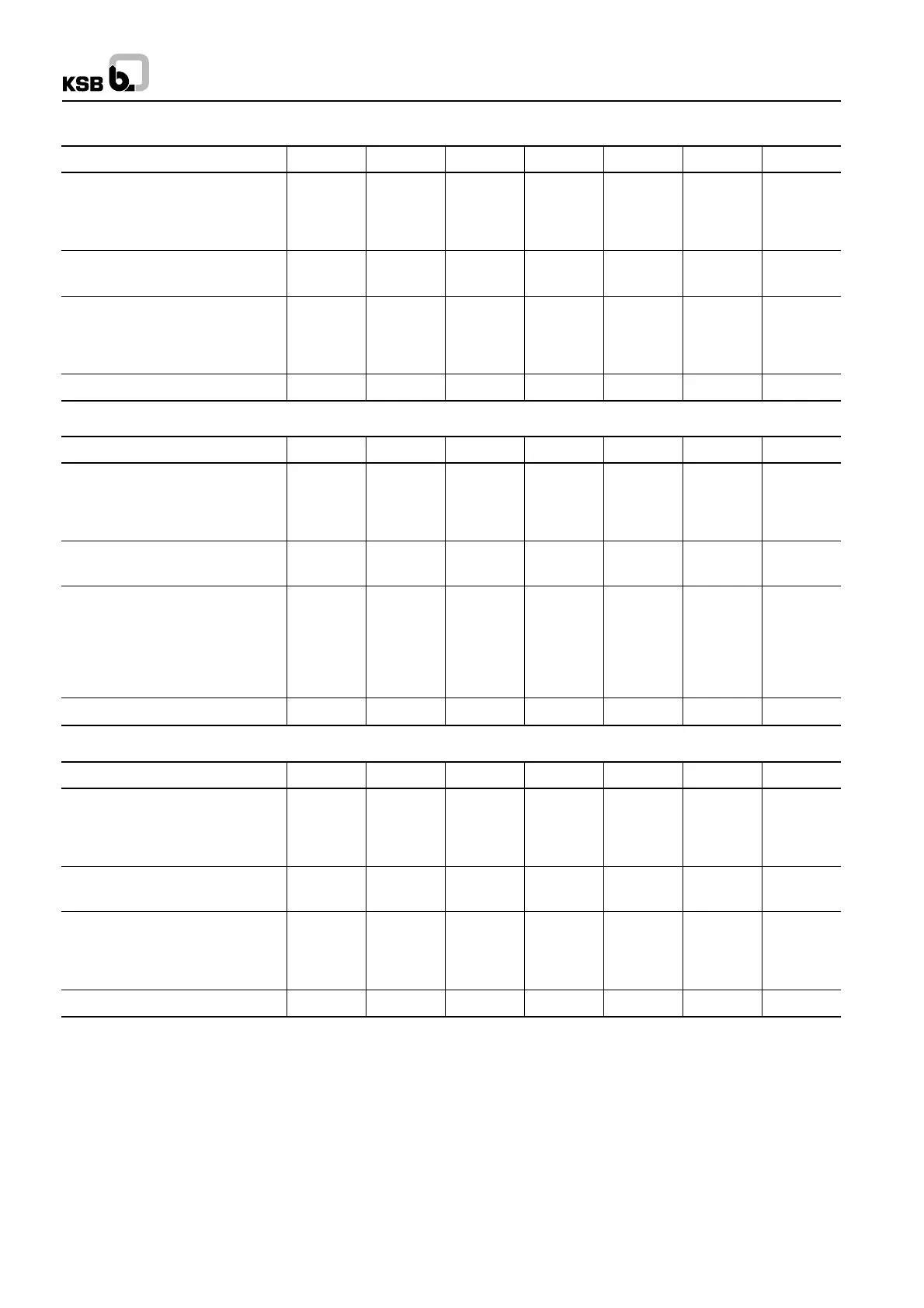

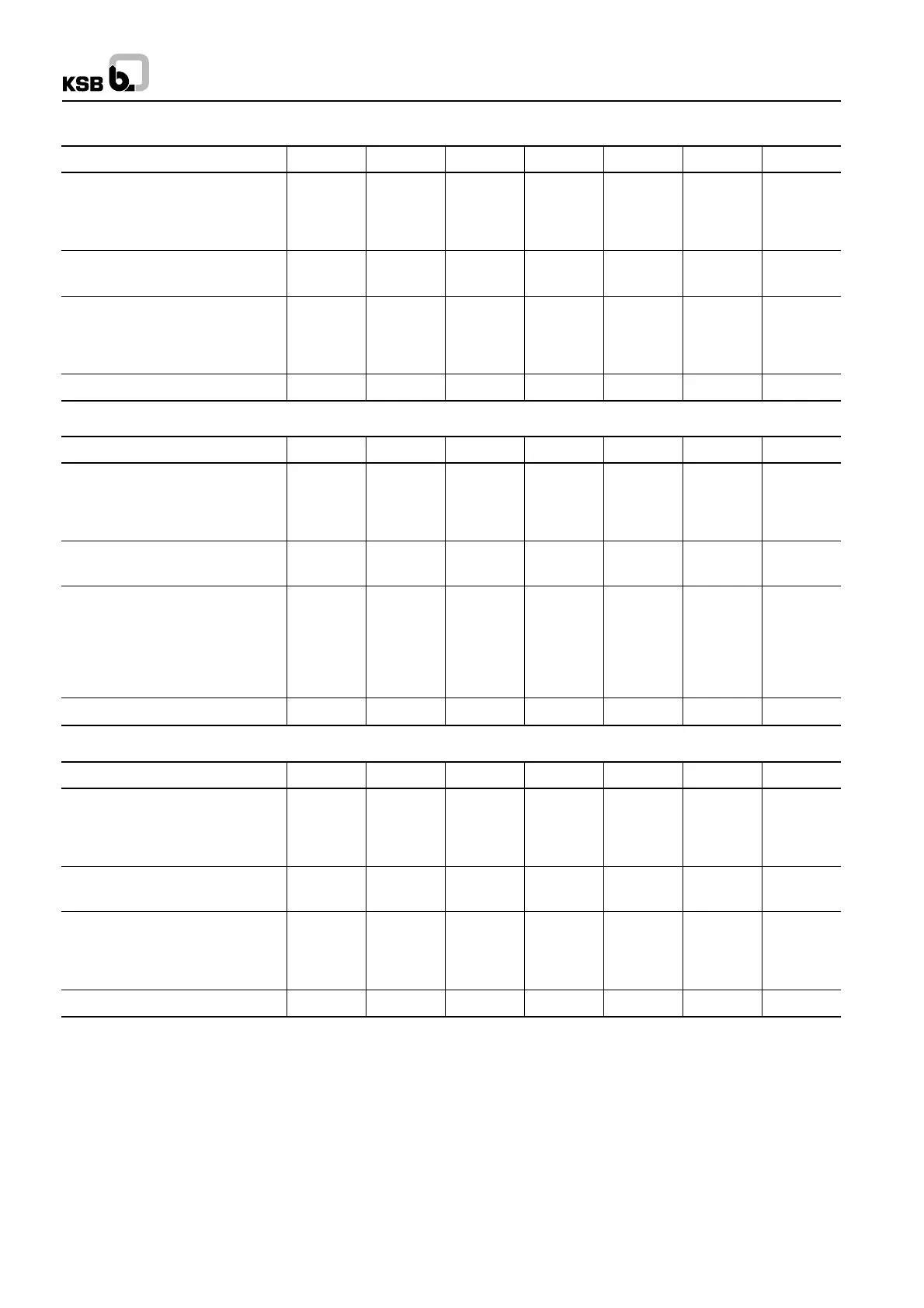

WK

Standard Construction

Pump size 40 50 65 80 100 125 150

Drive end :

cylindrical roller bearing NU 206 K NU 207 K NU 207 K NU 208 K NU 208 K NU 210 K NU 410

designation in accordance C 3 C 3 C 3 C 3 C 3 C 3 C 3

with DIN 5412

Adaptor sleeve in

accordance with DIN 5412

H 206 H 207 H 207 H 208 H 208 H 210 ---

Non Drive end :

Deep groove ball bearing

designation in accordance 6403/C 3 6404/C 3 6404/C 3 6405/C 3 6405/C 3 6405/C 3 6410/C 3

with DIN 625

Oil fill in litres 0.16 0.18 0.18 0.25 0.25 0.28 0.45

Heavy Duty Bearing Bracket

Pump size 40 50 65 80 100 125 150

Drive end :

cylindrical roller bearing NU 206 K NU 207 K NU 207 K NU 208 K NU 208 K NU 210 K NU 410

designation in accordance C 3 C 3 C 3 C 3 C 3 C 3 C 3

with DIN 5412

Adaptor sleeve in

accordance with DIN 5415

H 206 H 207 H 207 H 208 H 208 H 210 ---

Non Drive end :

Angular contact ball bearing

Din 628, 7305 BG 7306 BG 7306 BG 7307 BG 7307 BG 7309 BG 7310 BG

matched pair, X arrangement

7305 B. UA 7306 B. UA 7306 B. UA 7307 B. UA 7307 B. UA 7309 B. UA 7310 B. UA

Manufacturer SKF

FAG

Oil fill in litres 0.65 0.70 0.70 0.90 0.90 1.2 1.2

Drive at both Ends

Pump size 40 50 65 80 100 125 150

Suction side :

cylindrical roller bearing NU 206 K NU 207 K NU 207 K NU 208 K NU 208 K NU 210 K NU 410

designation in accordance C 3 C 3 C 3 C 3 C 3 C 3 C 3

with DIN 5412

Adaptor sleeve in

accordance with DIN 5412

H 206 H 207 H 207 H 208 H 208 H 210 ---

Discharge side :

Deep groove ball bearing

designation in accordance 6305/C 3 6306/C 3 6306/C 3 6307/C 3 6307/C 3 6308/C 3 6410/C 3

with DIN 625

Oil fill in litres 0.16 0.18 0.18 0.25 0.25 0.28 0.45

Fig. 10 Bearing end oil requirement table

In case of the pump construction with drive at both ends, the

bearing arrangement at the suction end corresponds to the

standard construction. At the discharge end, deep groove ball

bearings in accordance with DIN 625 are fitted, but they are of

bearing series 63.

See Fig. 10 ‘‘Bearing and oil requirement table’’ for precise

bearing designation and size for the individual pump sizes.

Splash ring (507) on shaft (210) prevent the penetration of

any leakage liquid from the stuffing box into the bearing

housing.

1.4 Lubrication

1.4.1 Oil Lubrication

Standard construction WK pumps are provided with oil splash

lubrication. The antifriction bearings are slightly submerged in

the oil sump, ensuring perfectly satisfactory lubrication at all

times. The max. oil level is automatically attained during topping

up when oil starts pouring out of the over-flow holes in the

bearing covers (360/361).

On request, we can fit constant level oilers (638), which will

necessitate the sealing of the shaft against the bearing bracket

by means of felt rings (422.1) (See Fig. 11 to 13).

3

Loading...

Loading...