4

OPERATION LEISTER Uniplan E

Operational condition

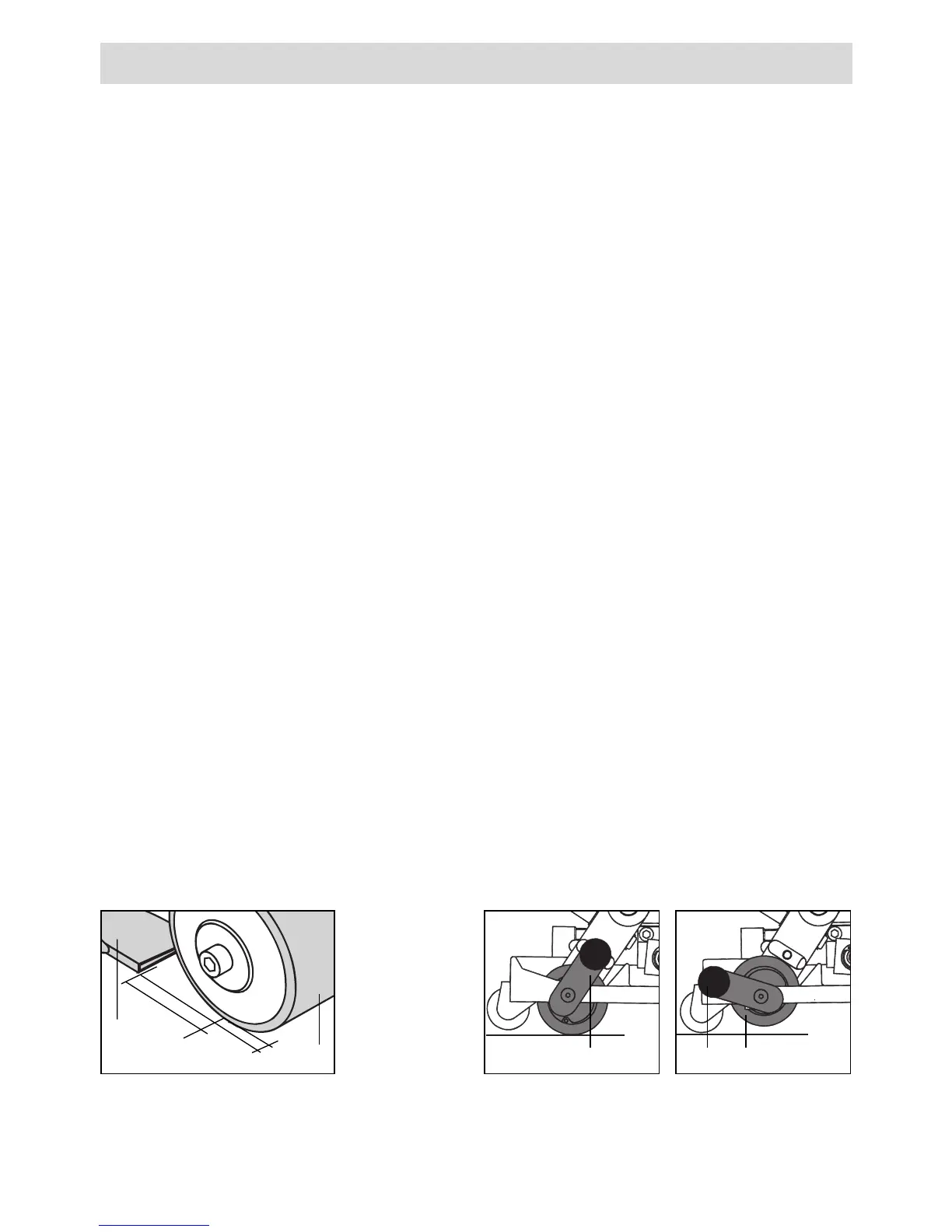

• Check the nozzle’s basic setting. (Detail A)

• Automatic drive

Automatic drive is adjusted as required, depending on nozzle position by means

of switch pin (26) and set screw (27).

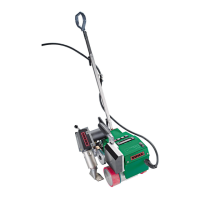

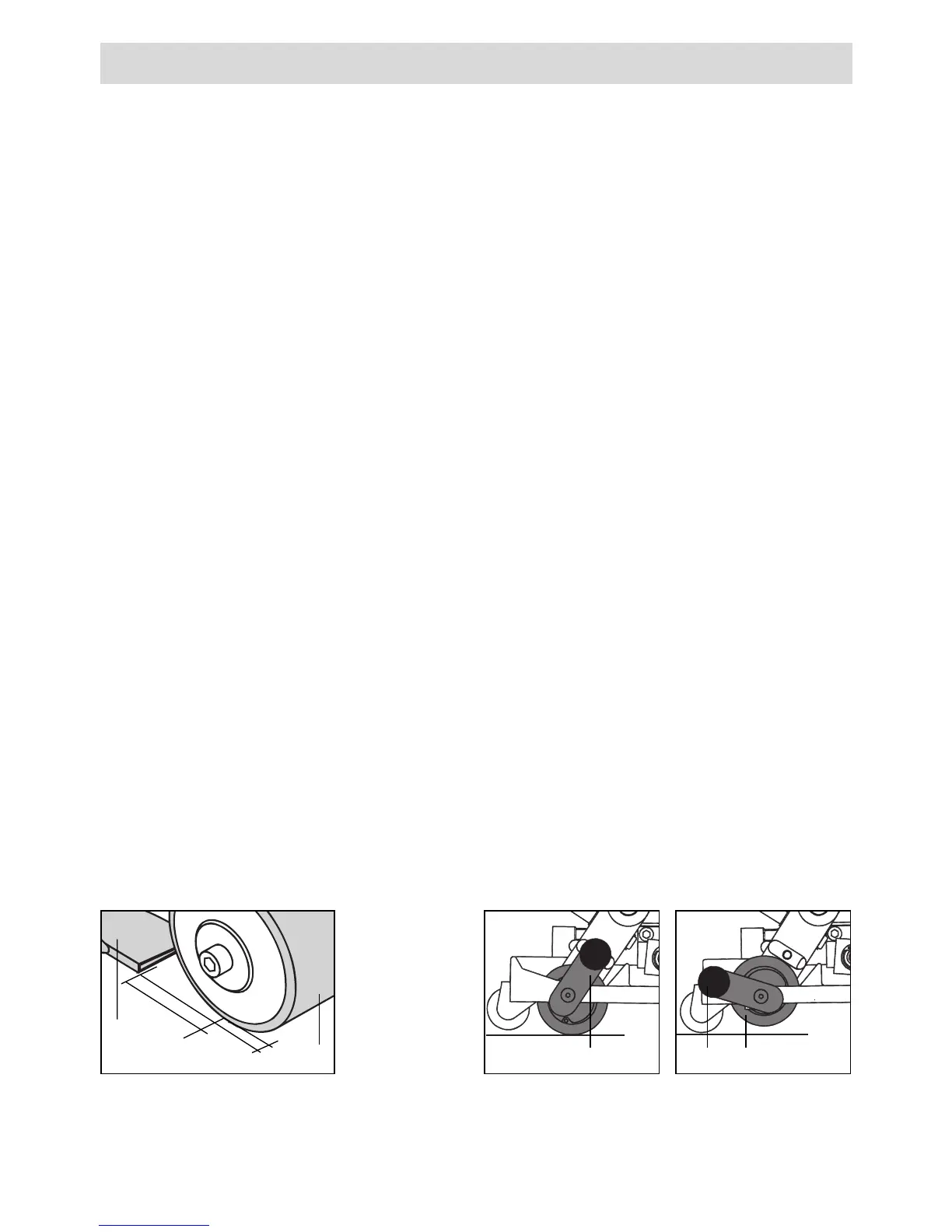

• Guide roller

According to the application, the guide roller (25) is set to "active" (operational) or

"deactive" (non-operational) by means of guide roller knob (24) and guide roller

lever (23) (see Details B and C). The guide roller (25) causes the automatic welding

machine to carry out a straight run to the edge of the welding seam.

• Connect tool to the mains. Mains voltage must correspond with the voltage

rating stated on the tool.

• Switch on tool using main switch (17). Hot air blower (3) starts automatically.

• Important: undervoltage

In case the maximum temperature is not reached, reduce air volume by means of

manuel air vane (14) and potentiometer for air flow (20).

Tool positioning

• Swivel hot air blower (3) using swivel lever (22) up to the stop.

• Operate lifting device (11) by means of lifting device lever (16) so that

drive/pressure roller (6) and drive roller (9) are at no-load.

• If welding is being carried out by means of guide roller (25), lock guide roller lever

(23) into support bracket (12) (see Detail B).

• Position automatic welding machine into the overlap of the material to be welded.

The outside edge of drive/pressure roller (6) and guide roller (25) must line up with

the overlap edge of the material to be welded.

• Activate lifting device (11) by means of lifting device lever (16) so that the auto-

matic welder is ready to start.

Detail A Detail B Detail C

1–2 mm

40 – 50mm

6

4

24 2523

Guide roller

operational

Guide roller

non-opera-

tional

Loading...

Loading...