Do you have a question about the Leister UNIPLAN 300 and is the answer not in the manual?

Specifies the intended applications for the UNIPLAN 300/500, including materials and welding types.

Defines uses that are considered improper or prohibited for the device.

Directs users to essential safety guidelines and warnings for device operation.

Details electrical supply needs, including cable specifications and generator compatibility.

Comprehensive list of technical parameters for both UNIPLAN 300 and UNIPLAN 500 models.

Instructions for safely packing and moving the hot-air welder, including cooling procedures.

Guidance on finding the device's model and serial number on the specification plate.

Lists all accessories and components provided with the UNIPLAN 300 and UNIPLAN 500.

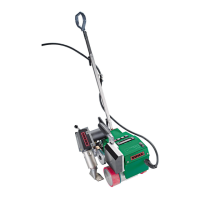

Labeled diagrams identifying all major parts of the UNIPLAN 500 and UNIPLAN 300 welders.

Detailed explanation of the UNIPLAN 500 control panel's buttons, displays, and key functions.

Interpretation of the LED lights on the heating and drive controls for operational status.

How warnings and errors are displayed and what actions to take, with references to further details.

Explains symbols in status display areas 1 and 2, including general warnings and power supply notes.

Defines symbols related to welding parameters (speed, temperature, air volume) and information boxes.

Explains symbols used for navigating the UNIPLAN 500 menu system.

Step-by-step instructions for creating, saving, and selecting custom welding parameter recipes.

Procedures for modifying existing recipes and choosing the desired profile for operation.

Guide for assigning unique names to user-defined welding recipes via the interface.

Differentiates between Basic and Advanced modes for accessing setup options and recipes.

How to set up the energy-saving Eco Mode and the device's standby behavior.

Retrieving operational data like runtime hours and viewing firmware/production details.

Adjusting system units, display contrast, backlight, and viewing active warnings.

Monitoring real-time parameters and restoring all settings and recipes to factory defaults.

Instructions on how to display the total distance covered by the device during the current day.

Procedures for resetting the daily distance counter and enabling/disabling the control panel key lock.

Essential checks before operation, including power, safety, and nozzle alignment.

Guidance on fitting accessories like the guide bar and adjusting key parts for optimal performance.

Steps for installing the guide bar, adding weights, and setting the overlap guide roller.

Instructions for fine-tuning the starting switch and ensuring the round belt is correctly tensioned.

How to safely start the device, including power connection and initial screen display.

Detailed steps for setting and adjusting individual welding parameters like speed and temperature.

Instructions on correctly positioning the welder and preparing the materials for a successful weld.

Steps for engaging the welding nozzle, starting the drive, and beginning the welding operation.

Techniques for guiding the device along the seam and observing welding parameters during the process.

Procedures for finishing the weld, retracting the hot-air blower, and safely powering down the unit.

A comprehensive table detailing warning and error messages, their codes, and troubleshooting solutions.

Overview of the UNIPLAN 300 control panel, including keys, display fields, and common symbols.

Explanation of the LED indicators on the heating control for the UNIPLAN 300.

Interpretation of the drive status LED and instructions for changing parameter units like temperature and speed.

Procedures for ensuring operating readiness, checking connections, and safety protocols.

Steps for turning on the UNIPLAN 300 and configuring the initial welding parameters.

Guidelines for preparing the material and starting the welding process for the UNIPLAN 300.

Techniques for guiding the device during welding and observing performance metrics.

Steps for completing the weld, retracting components, and safely turning off the UNIPLAN 300.

A list of error codes, descriptions, and solutions for common UNIPLAN 300 issues.

How to acknowledge and act upon maintenance interval notifications for the UNIPLAN 300.

Answers to common user queries and tips for resolving operational issues.

Lists other pertinent documentation, such as safety instructions for related welding equipment.

Statement of conformity with relevant EU directives and the application of harmonised standards.

Details the warranty coverage, exclusions, and claim procedures for the device.

Provides essential contact details for Leister Technologies AG for sales and technical support.

| Brand | Leister |

|---|---|

| Model | UNIPLAN 300 |

| Category | Welding System |

| Language | English |