69

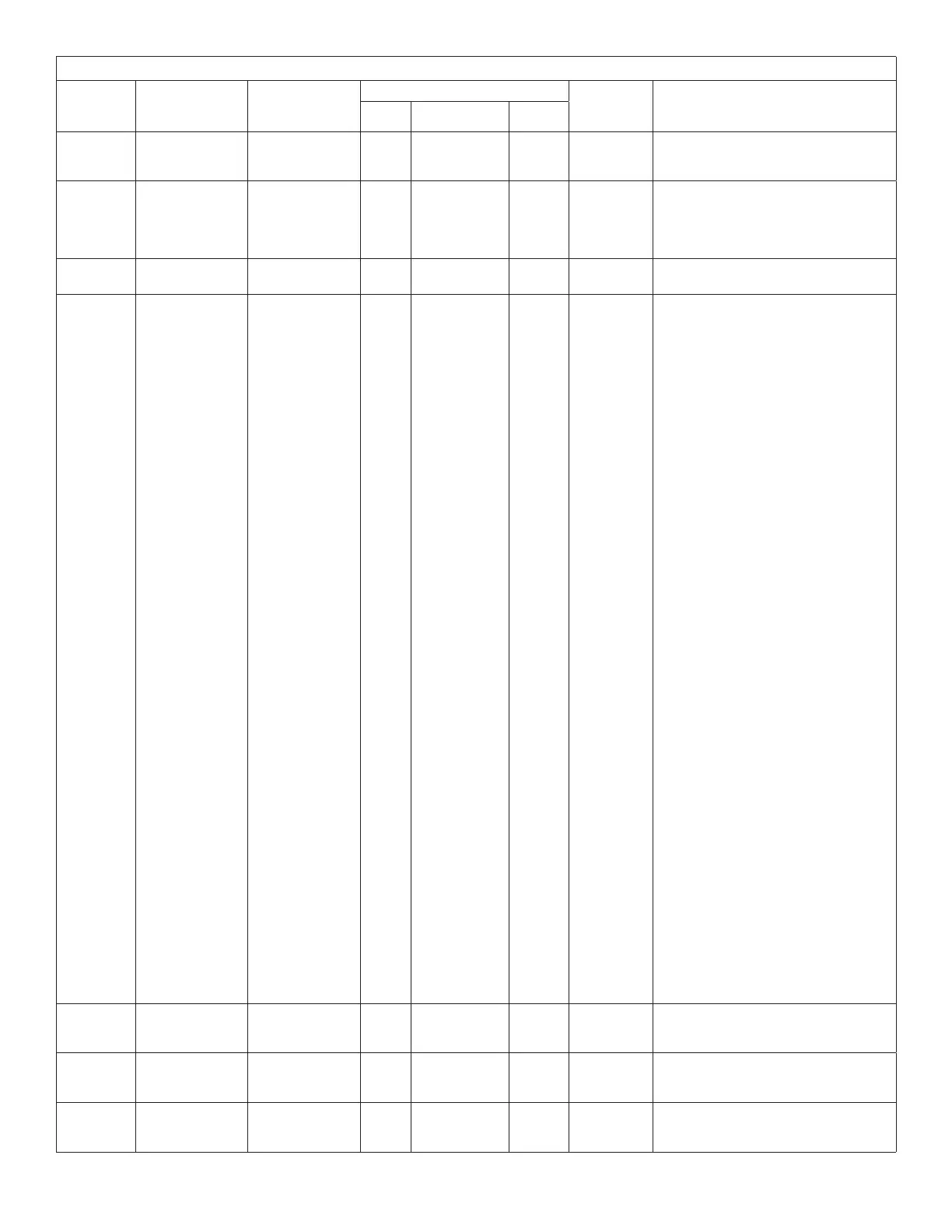

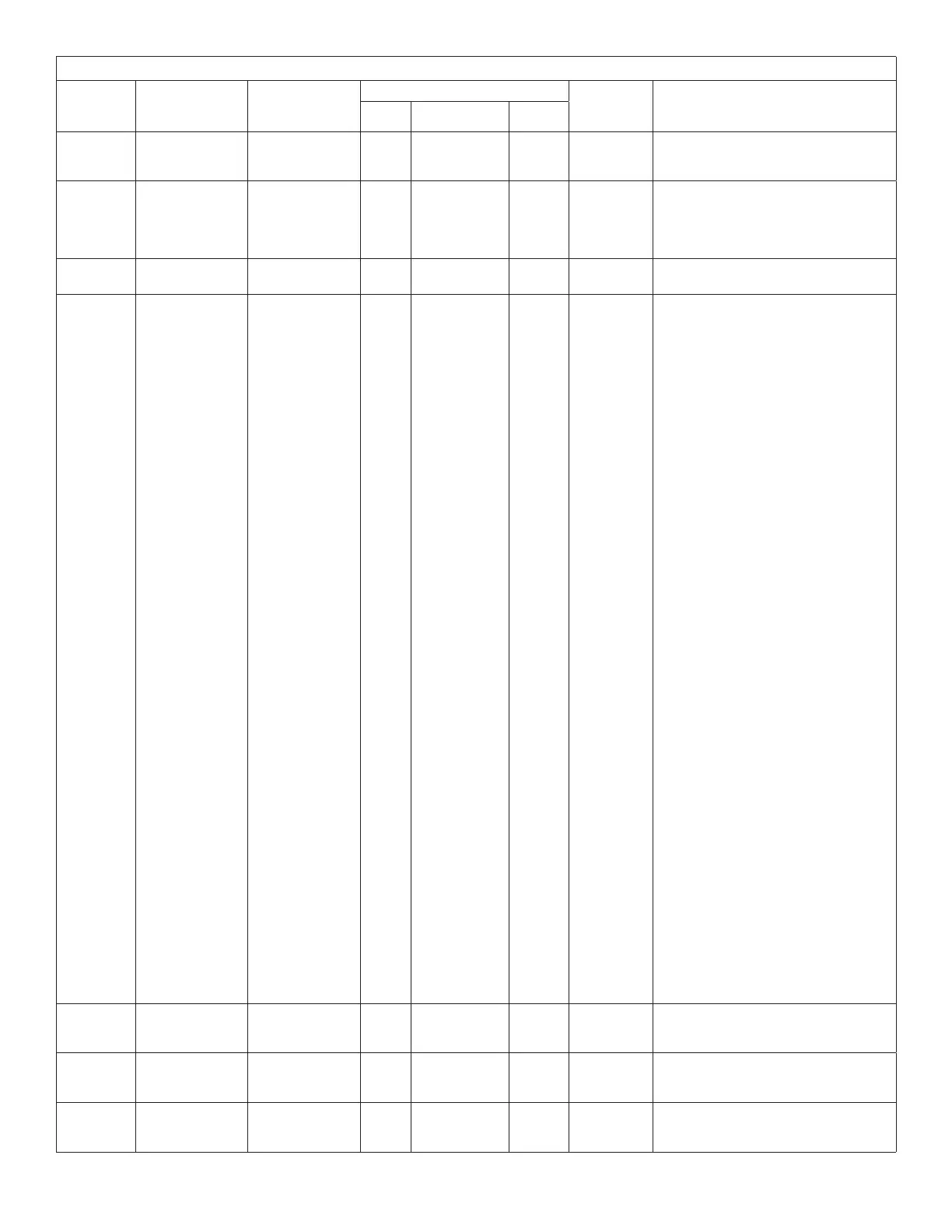

Table 12. CORE Control System Unit Parameters

Control

Parameter

No

Screen Name

Parameter Short

Description

Control Value

Units Description

Min. Default Max.

355

GP A03 MAX

OUPUT

General Purpose

A03 Maximum

Output

0 100 100 %

Analog output channel 3 Maximum

output.

356 GP A03 SOURCE

General Purpose

A03 Source

1 1 3 SOURCE

Source/feedback for the PID loop.

• 1 = Analog input 1 on GP3 A03

• 2 = Analog input 2 on GP3 A03

• 3 = Analog input 3 on GP3 A03

357

GP A03 CYCL

INTRVL

General Purpose

A03 Cycle Interval

0 1 180 Seconds Frequency of execution of PID loop.

358 GP D01 MODE

General Purpose

D01 Mode

0 0 127 Input Source

GP3 Digital Out Control Mode = X + 32*Y

+ 16*Z

Input Sources X:

• 0 = None.

• 1 = Compressor 1 duty cycle.

(Compressor crankcase heater

function)

> On when outdoor air

temperature is > = Parameter

364 seconds have passed with

compressor 1 off.

> Off when outdoor air

temperature > Parameter 362

+3°F(xeddead-band)or

compressor 1 is turned on.

• 2 = On when Occupied

• 3 = On when blower on.

• 4 = On when heating demand

• 5 = On when cooling demand

• 6 = On when heating or cooling

demand

• 7 = System RH (use Parameter 361)

• 8 = System IAQ (use Parameter

360)

• 9 = System OAT (use Parameter

362)

• 10 = On based on GP3 Temperature

Sensor 1 (use Parameter 362)

• 11 = On based on GP3 Temperature

Sensor 2 (use Parameter 362)

• 12 = On based on GP3 AI1 (use

Parameter 359)

• 13 = On based on GP3 AI2 (use

Parameter 359)

• 14 = On based on GP3 AO1 (use

Parameter 359)

• 15 = On based on GP3 AO2 (use

Parameter 359)

• Algorithm Y for Input Sources 7-15

(see 507242-01, Prodigy Application

Guide for further details).

359

GP D01 SP

VOLTS

General Purpose

D01 Set Points

Volts

0 0 10 Volts

General Purpose D01 Digital output

control mode set point.

360 GP D01 SP PPM

General Purpose

D01 Set Point

Parts Per Million

21 996 1996 PPM

General Purpose D01 Digital output

control mode set point.

361

GP D01 SP

PERCENT

General Purpose

D01 Set Point

Percentage

0 0 100 %

General Purpose D01 Digital output

control mode set point.

Loading...

Loading...