Do you have a question about the Lennox ZGB Series and is the answer not in the manual?

| Brand | Lennox |

|---|---|

| Model | ZGB Series |

| Category | Air Conditioner |

| Language | English |

Provides overview of ZGB series, capacities, and heat options.

Highlights critical safety warnings regarding installation, electrical hazards, and sharp edges.

Lists available accessories for cooling, heating, and blower systems.

Details economizers, indoor air quality sensors, roof curbs, and ceiling diffusers.

Covers nominal tonnage, efficiency, cooling capacity, SEER, and EER.

Details gas heat inputs, outputs, temperature rise, and blower data.

Provides CFM, Watts, RPM for various static pressures for direct drive models.

Lists CFM, RPM, and BHP for belt drive models across different static pressures.

Details belt drive kit part numbers, motor HP, and RPM ranges.

Lists air volume exhausted based on return air system static pressure.

Provides static pressure drops for options like heat exchangers and economizers.

Details air resistance and air throw for various ceiling diffuser models.

Lists compressor, fan, and power exhaust electrical ratings for direct drive models.

Details electrical data for belt drive models across different voltages and phases.

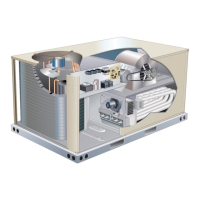

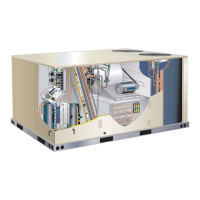

Illustrates the physical layout of major components within the unit.

Identifies components within the ZGB control box.

Covers ESD procedures and lists key control box components and their functions.

Explains the functions of the burner control board and LED status indicators.

Describes heating sequence, compressor operation, and safety precautions.

Details cooling circuit components and operational notes.

Shows the layout of refrigeration components like evaporator coil, compressor, and condenser coil.

Stresses adherence to installation instructions and codes for proper setup.

Outlines heating start-up steps and critical safety warnings before lighting.

Illustrates proper locations for measuring static pressure for blower performance.

Details blower assembly and how to adjust motor pulley for RPM and CFM.

Explains proper belt tensioning, alignment, and checking procedures.

Lists part numbers for blower drive components, including pulleys and belts.

Shows the heat exchanger assembly and mentions the high-temperature limit switch.

Details heat exchanger design, orifice function, and primary limit switches.

Explains the function and importance of the combustion air prove switch.

Describes the combustion air inducer motor, capacitor, and gas valves.

Details the spark electrode, its function, and proper gapping procedures.

Covers flame sensor mounting, operation, and ignition system checks.

Provides critical safety warnings for heating start-up, including electrical shock and fire hazards.

Details pre-lighting safety procedures and gas valve operation steps.

Explains how to turn off gas to the appliance and perform emergency shutdowns.

Describes cooling start-up sequence, compressor phasing, and refrigerant circuit details.

Outlines the procedure for checking and adjusting refrigerant charge using pressure and temperature.

Covers gas piping requirements, pressure testing, and supply pressure checks.

Details checking and adjusting manifold pressure, including safety precautions.

Explains proper gas flow checks, flame sensing procedure, and heat exchanger inspection.

Details periodic checks for the cooling system, including refrigerant charge.

Provides guidance on filter checks, replacement, and motor lubrication requirements.

Outlines procedures for inspecting and cleaning burners and checking the ignitor gap.

Details maintenance for the combustion air inducer, flue passageway, and evaporator/condenser coils.

Describes the annual inspection and cleaning of the supply blower wheel.

Covers Z1CURB roof frames and supply/return transitions for installation.

Details supply/return diffusers and factory/field-installed economizer options.

Explains economizer operation, damper control, and sensor functions for horizontal and downflow units.

Describes the IAQ sensor's role in controlling outdoor air based on CO2 levels.

Details how to set the free cooling setpoint based on temperature and humidity.

Explains how to adjust damper minimum position and DCV settings for optimal ventilation.

Outlines economizer operation based on thermostat demand and outdoor air conditions.

Refers to charts and tables for calculating minimum fresh air percentage.

Covers installation and adjustment of motorized and manual outdoor air dampers.

Explains the function of the power exhaust relay K65 in activating the exhaust fan.

Describes field-installed power exhaust fans and various control system options.

Details the indoor air quality sensor and LP/propane conversion kits.

Provides a comprehensive list of all components and their associated identifiers.

Lists the function of each terminal jack and plug connection for wiring.

Shows the primary wiring schematic for various voltage configurations.

Displays the secondary wiring schematic, including optional components and connections.

Details the sequence for power, blower activation, and economizer functions.

Explains the step-by-step process for cooling and both stages of heating demands.

Illustrates the typical wiring for a two-speed blower system.

Provides notes on wiring practices and a legend for schematic symbols.

Loading...

Loading...