Commissioning

Commissioning steps

6

35

EDS82ZAFPC010 EN 4.0

Detailed

information

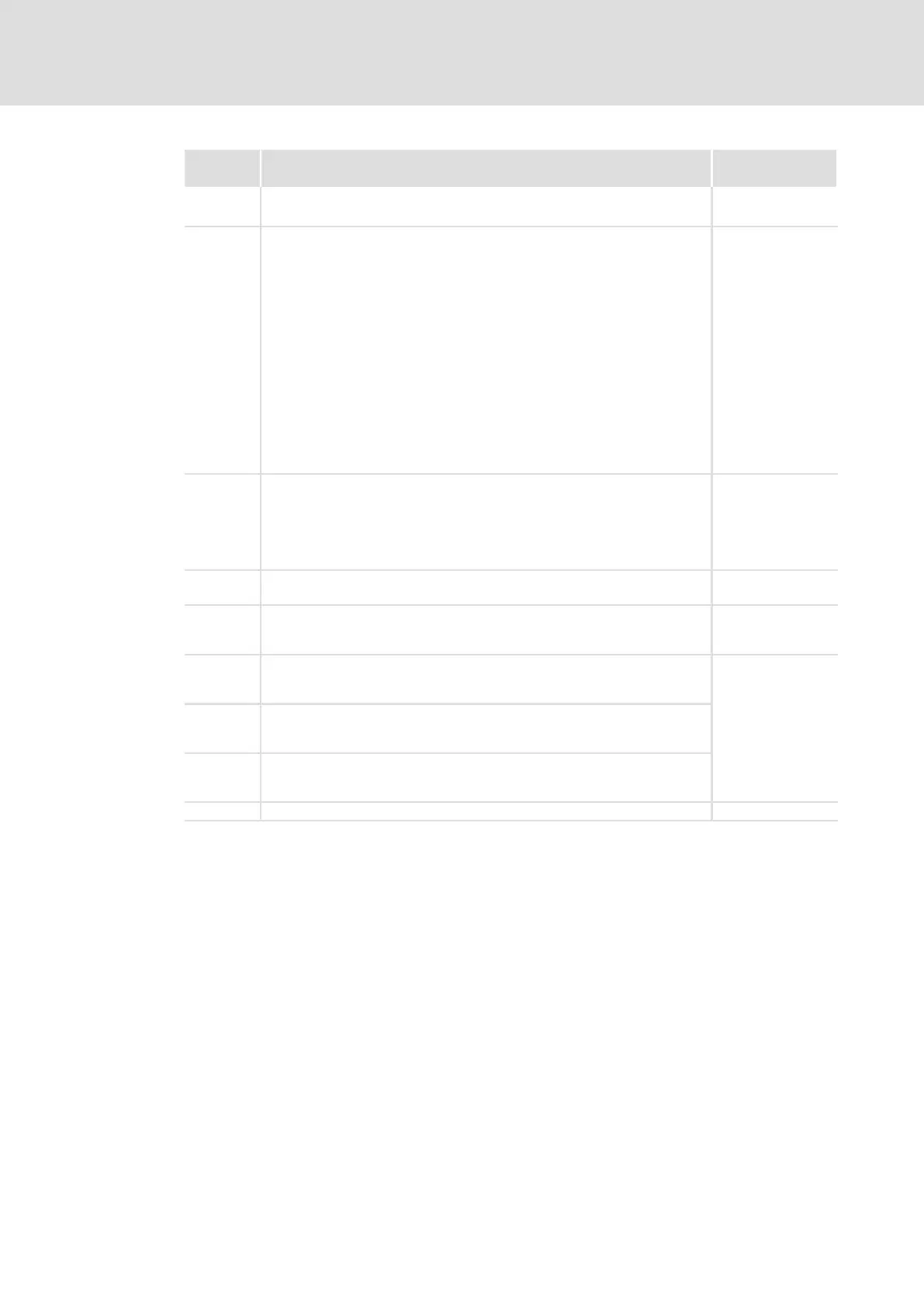

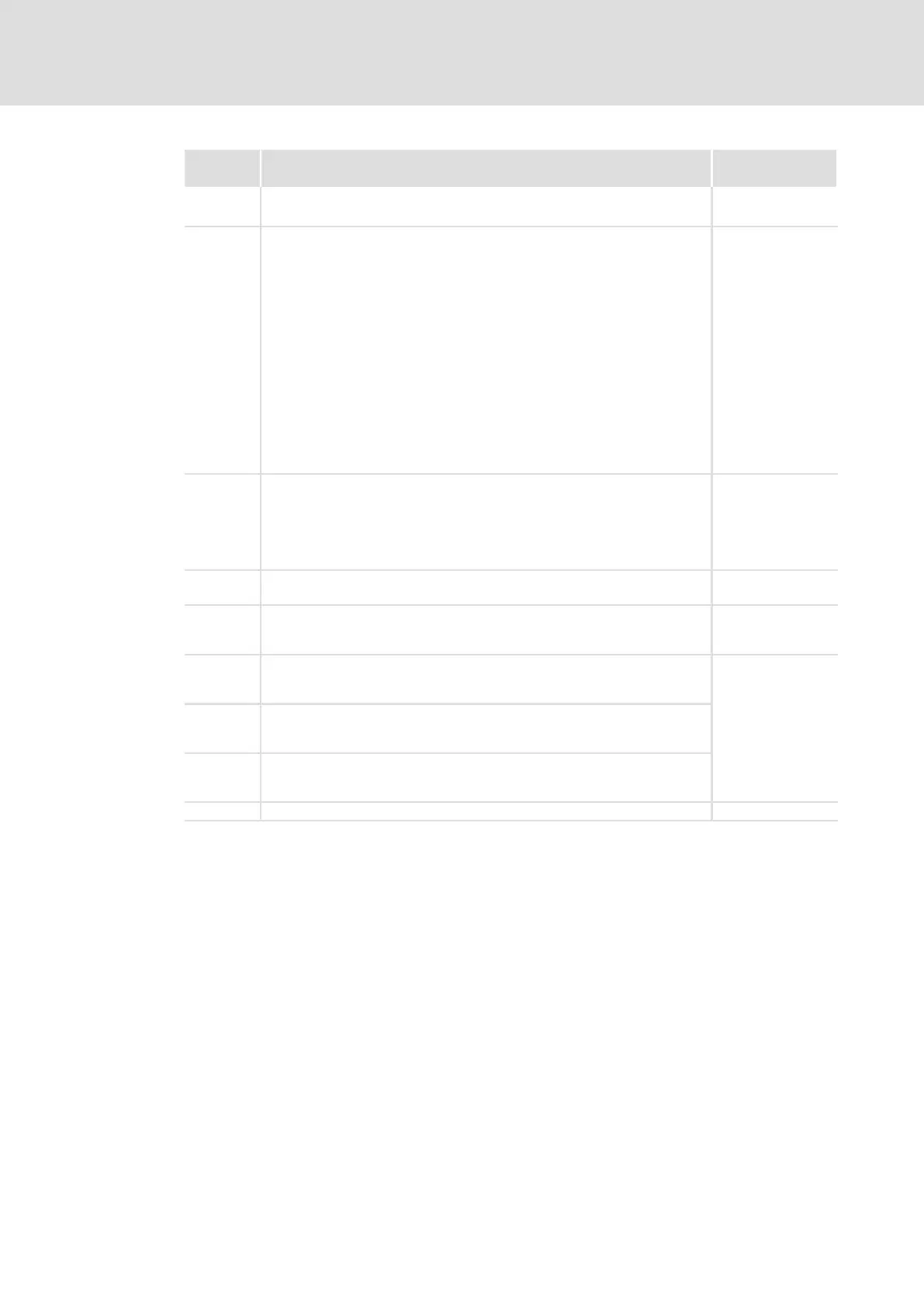

DescriptionStep

POW9: PWM voltage (MCTRL1−VOLT−ADD)

POW10: PWM angle (MCTRL1−PHI−ADD)

9.

Assign process data output words of the standard device to the process data

input words (PIW) of the master via C1510.

PROFIBUS

communication

manual

Lenze setting:

PIW1: DRIVECOM status word (DRIVECOM STAT)

PIW2:

Output frequency with slip (MCTRL1−NOUT+SLIP)

PIW3:

Output frequency without slip (MCTRL1−NOUT)

PIW4:

Apparent motor current (MCTRL1−IMOT)

PIW5:

Actual process controller value (PCTRL1−ACT)

PIW6:

Process controller setpoint (PCTRL1−SET1)

PIW7:

Process controller output (PCTRL1−OUT)

PIW8:

Controller load (MCTRL1−MOUT)

PIW9:

DC−bus voltage (MCTRL1−DCVOLT)

PIW10:

Ramp function generator input (NSET1−RFG1−IN)

10.

Enable process output data via C1512 = 65535.

l Only required if C1511 has been changed.

l Deactivate process data words that are not used by setting the respective

subcode of code C1511 to 0.

l The value in C1512 is volatile, and all process data are enabled after every

switch−on.

11. Enable standard device via terminal 28 (CINH).

l Set terminal 28 to HIGH level.

12. Enter the setpoint.

l The master transmits the setpoint via the process data output word

selected.

13. Change to the READY TO START status:

l The master transmits the DRIVECOM control word:

0000 0000 0111 1110

bin

(007E

hex

).

PROFIBUS

communication

manual

14. The standard device is in the READY TO START status.

l The master receives the DRIVECOM status word:

xxxx xxxx x01x 0001

bin

15. Change to the OPERATION ENABLED status.

l The master transmits DRIVECOM control word:

0000 0000 0111 1111

bin

(007F

hex

).

16. Now the drive starts up.

Loading...

Loading...