110

EN

USER

Rev. 03 - 07/2015 - Cod. 1501151 - Instruction manual for vacuum chamber packaging machines

Mod. C254-C308-C312-C412-C420

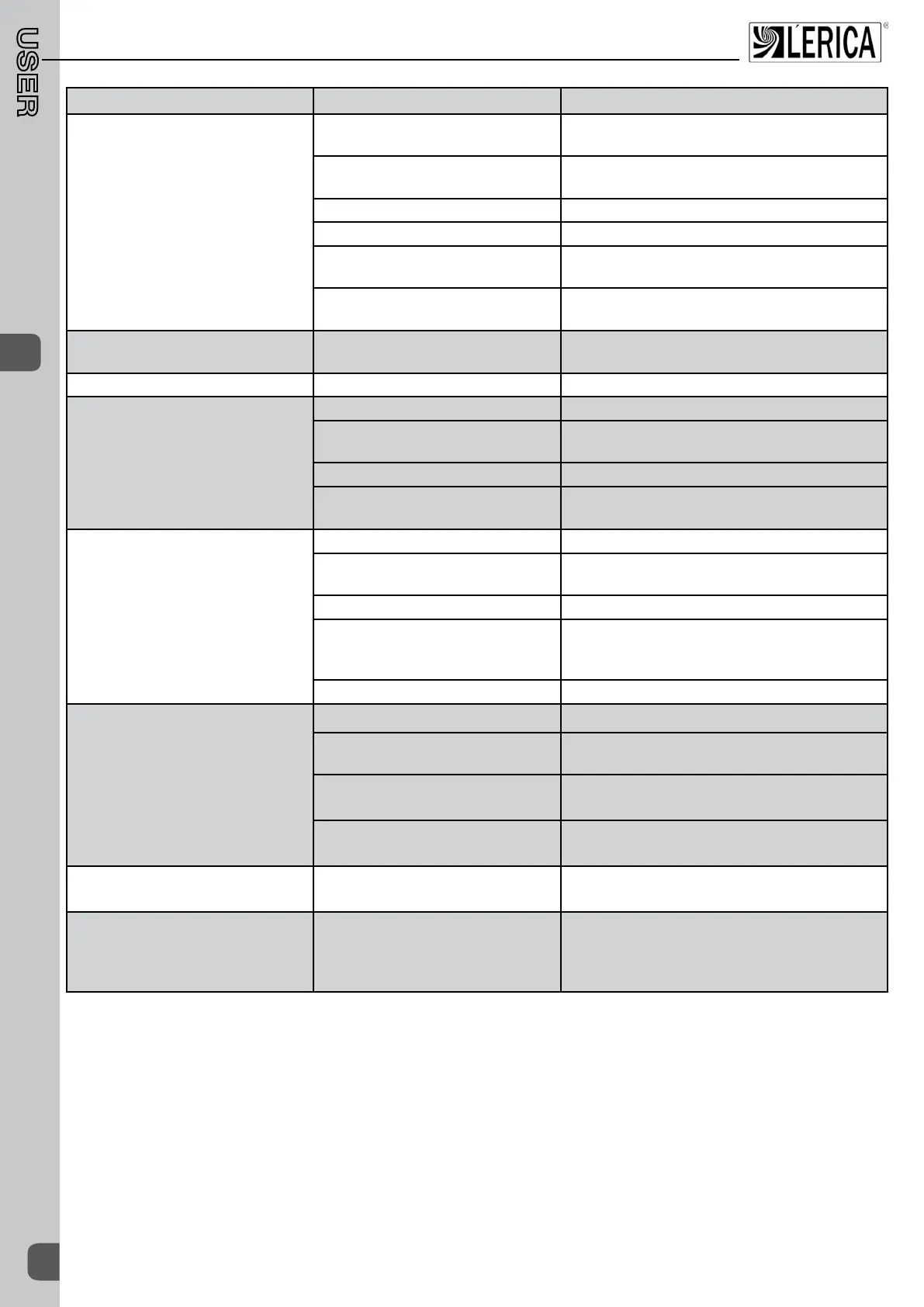

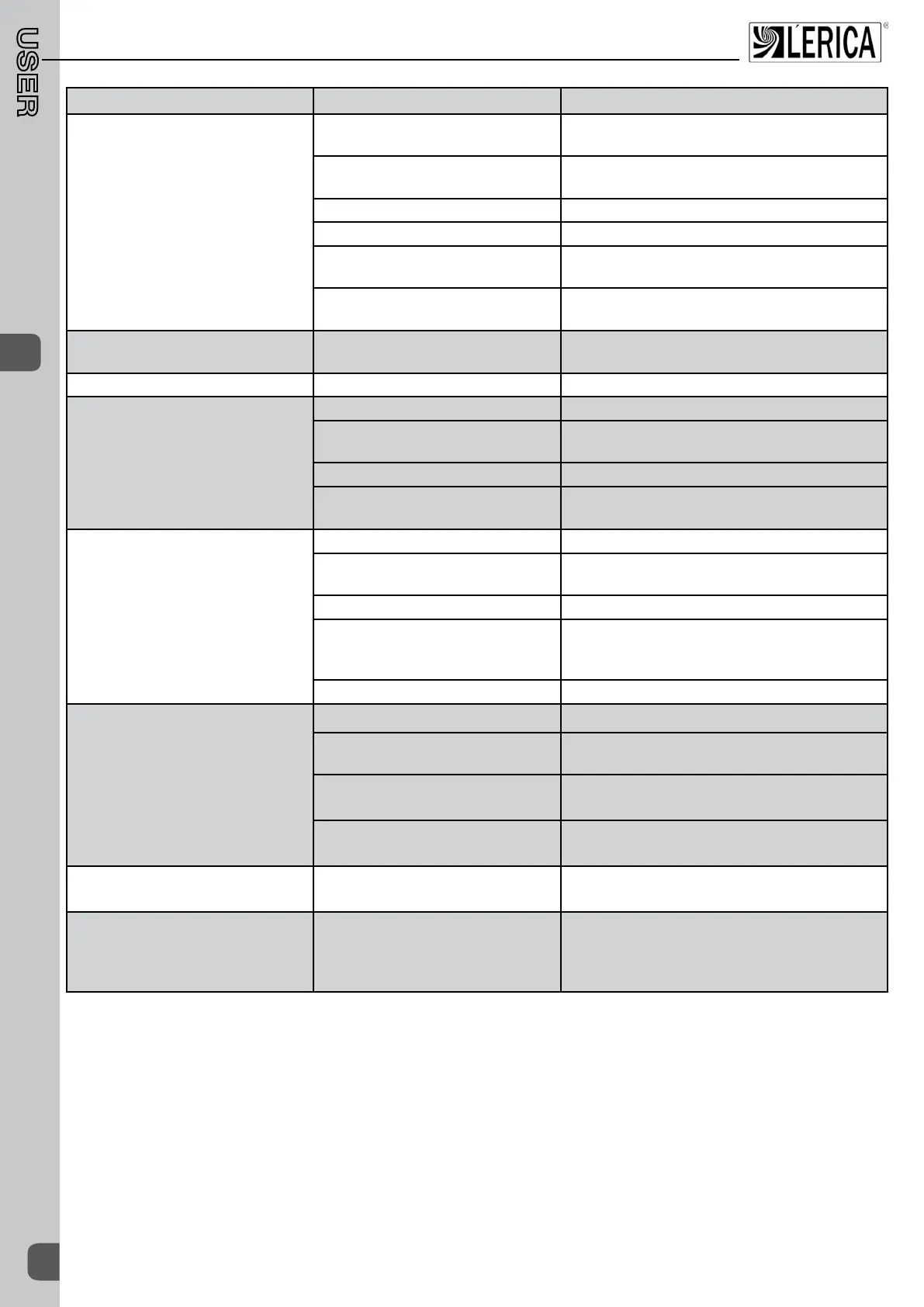

SOLUTION

• Bagpositionedincorrectly. • Placethebaginthecentreonthesealingbar

projectingby20mmbeyondit.

• Bagperforated. • Chooseathickerbagandwraptheproduct

withclinglmorsoftpaper.

• Sealinginsufcient. • Increasethesealingtime.

• Bag defective. • Changethebag.

• Dirtybagopen. • Useanewbagandavoidsmearingtheope-

ningwithoil,grease,etc.

• Bagtoobigortoosmallinrelation

toproductsize.

• Choose a bag size suitable for product di-

mensions.

• Sealing time too long. • Decreasethesealingtime.

• Sealingtimetooshort. • Increasethesealingtime.

• Dirtyweldingbarcontacts. • Clean contacts.

• Discontinued welding bar con-

tacts.

• Restore connection (contactyourservice

centre).

• Sealingbarwirebroken. • Changewire(contactaServiceCentre).

• Barliftingpistondefective • Replacethebarliftingpiston(contactaSer-

vice Centre).

• Sealingbardirty. • Cleansealingbar.

• Sealingtimeinsufcientforbasic

bagweight.

• Increase sealing time.

• Teoncoverworn. • ChangeTeoncover.

• Gaspercentageistoohigh(close

to70%)withrespecttothepacka-

gedproduct.

• Decreasethegasinjectiontime.

• Silicone worn. • Changesilicone.

• Gasushingtimeinsufcient.

• Increasethegasinjectiontime.

• Gas cylinder pressure Insuffi-

cient.

• Adjustpressureoncylinderreducerto1bar.

• Gas nozzle not inserted in bag

mouth.

• Repositionbagbyinsertinggasnozzleinthe

bagmouth.

• Cylindervalveorpressureredu-

cer closed.

• Open cylinder valves and adjust pressure

reducerto1.0bar.

• Gasvolumetoohigh. • Decreasethegasinjectiontime.

Vacuum not created in contai-

• Containerlidpositionedpoorlyor

lidvalveopen.

• Repositionthecontainerlid,makingsurethe

gasketisingoodconditionandinsertedinits

seatandthesuctionvalveonthelidisinthe

openposition.

Loading...

Loading...