Operation

41300324726_002_C0 - 10/2016 - © Leybold

4.6 Venting

Vent the turbomolecular pump each time it is shut down, in order to prevent

any return diffusion of oil vapors out of the forevacuum line and into the high-

vacuum side.

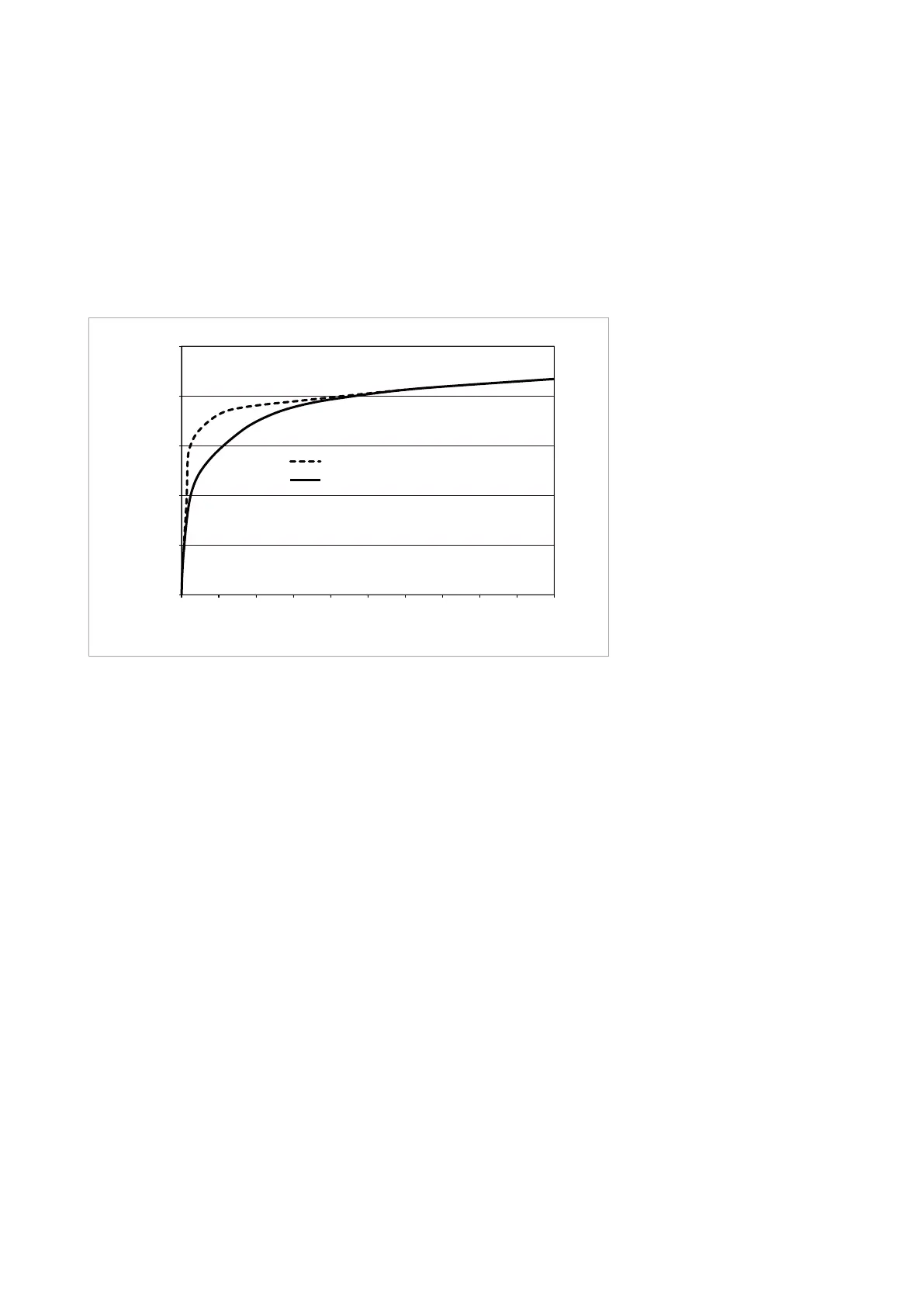

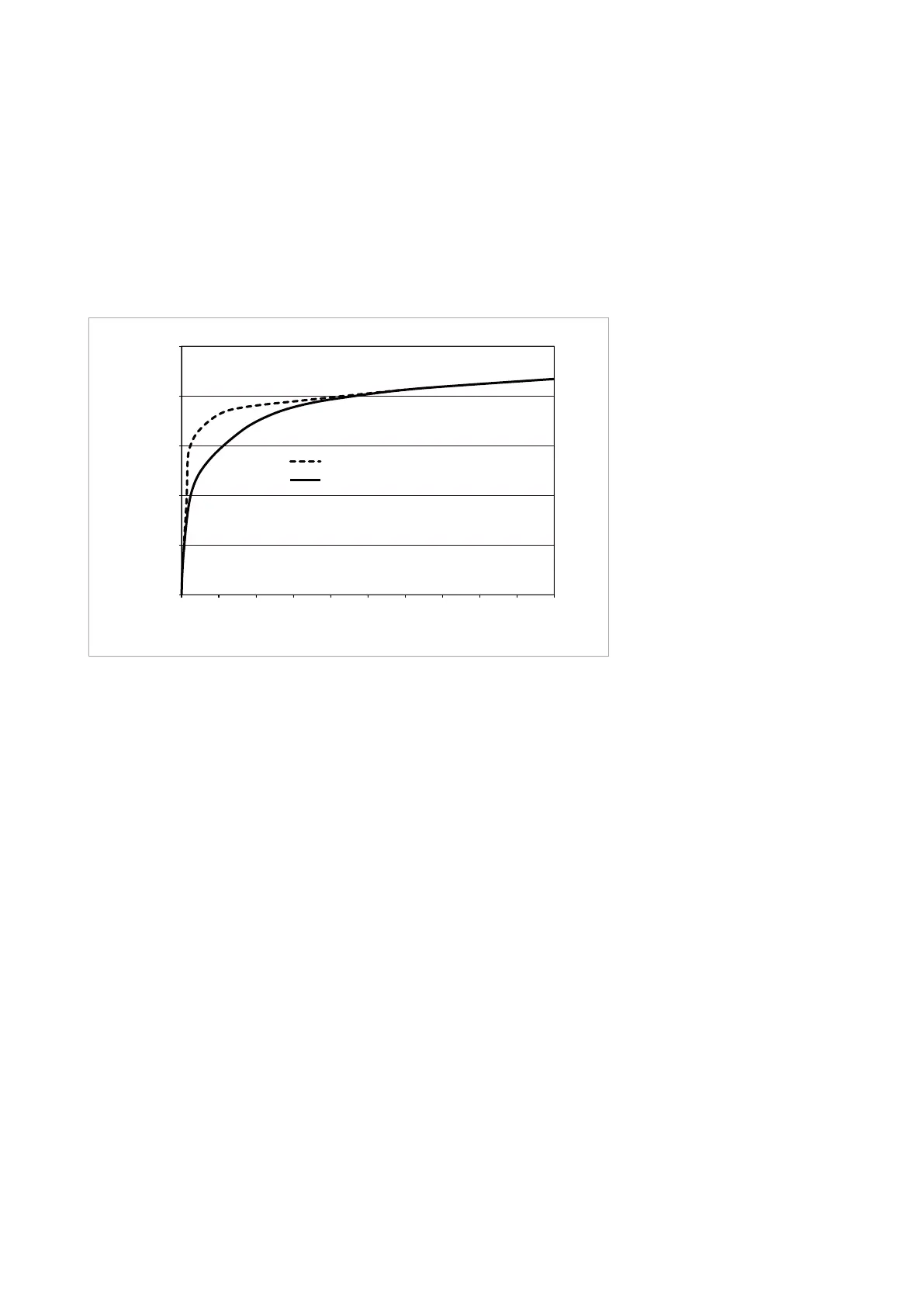

Druck

Zeit

10

-2

10

-1

1

10

10

2

10

3

0102030405060708090 100

Max. Vorvakuumdruck

Max. Hochvakuumdruck

mbar

s

Fig. 4.1 Pressure rise curve for safe venting

Time

Pressure

Max. forevacuum pressure

Max. high-vacuum pressure

Venting Methods

There are three different methods of venting the turbomolecular pump.

In the case processes requiring a purge gas, the pump must be vented via

the purge gas and venting valve when shutting the pump down.

When additionally venting the vacuum chamber, the venting function of the

purge gas and venting valve must be opened before opening the chamber

valve. This will ensure the presence of a higher pressure in the area of the

bearings compared to the remaining vacuum area. This will prevent particles,

dust or aggressive gases from being forced through the bearings into the not

yet vented motor chamber of the pump.

Cautious venting of the pump is possible from the high vacuum side, since

here the bearing forces will be lowest. When doing so, no free jet of gas must

be allowed to form on the rotor so as to avoid exposing the rotor to addition-

al forces.

When venting the pump through its foreline connection, neither oil nor parti-

cles may be entrained in the gas flow from the forevacuum side into the

pump.

Purge gas and venting valve

High vacuum side

Foreline connection

Loading...

Loading...