Installation

30 300324726_002_C0 - 10/2016 - © Leybold

3.4 Forevacuum connection

The high vacuum pressure level which can be achieved is a function of the

volume of gas flow Q to be pumped and the forevacuum pressure.

We recommend using our two stage TRIVAC-B pumps or dry compressing

pumps as backing pumps.

Connect the clean forevacuum line. The connecting flanges must be clean

and undamaged. The cross section of this line must be so wide that safe

opera tion of the pump can be ensured.

The forevacuum line must be tight. Hazardous gases can escape at leaks

or the gases being pumped can react with air or humidity.

Observe Safety Information 0.4.6.

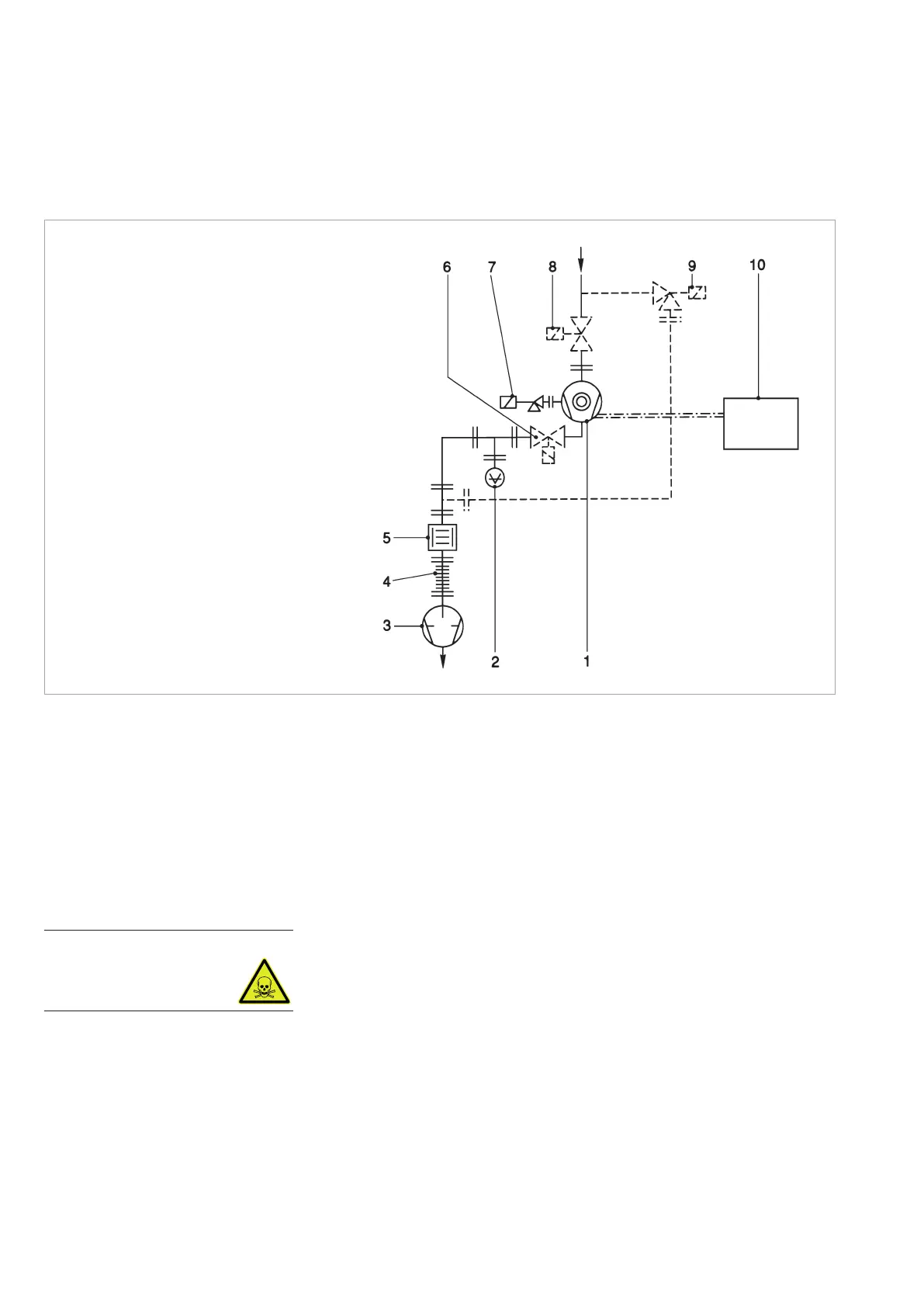

Fig. 3.6 shows schematically the design of a pump sys tem incorporating a

turbomolecular pump turbomolecular pump and a TRIVAC backing pump

with integral anti-suckback valve.

When using a backing pump not having an integrated an ti-suckback valve, a

separate safety valve should be used. The safety valve keeps oil from back-

streaming from the backing pump and into the turbomolecular pump when

the system is not running.

Forevacuum pump

DANGER

Safety valve

Fig. 3.6 Layout of a turbomolecular pump system

1 Turbomolecular pump

2 Forevacuum gauge point

3 Backing pump

4 Anti-vibration bellows

5 Sorption trap

6 Forevacuum valve

7 Purge gas and venting valve

8 Isolation valve

9 Valve in the roughing line

10 Frequency converter

— — — — roughing line; recommended if

shorter cycle times are to be achieved

— · — · — · — · drive and control line

Loading...

Loading...