Operation

14

3 Operation

Controlling the instrument through the keys START and STOP and the 9-way

PLC interface has equal priority. When controlling the instrument through

optional boards (Profibus or RS 485, for example), the keys and the 9-way

PLC interface are disabled.

3.1 Start-up

Switch the frequency converter on via the switch on the rear. After doing so,

the start-up self test begins.

The parameters stored in the EEPROM are read and the connected pump is

detected. After approximately 15 seconds the frequency converter is ready to

start.

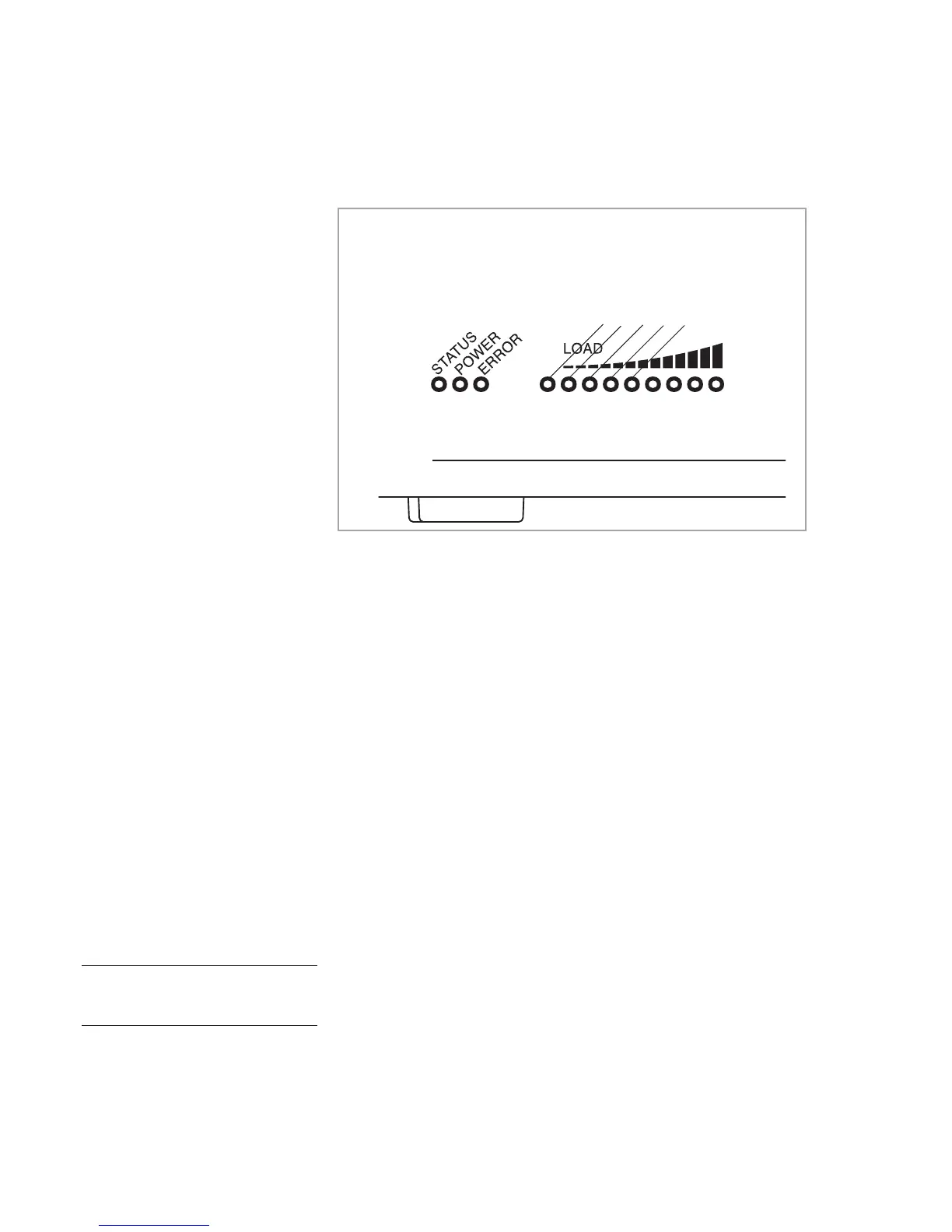

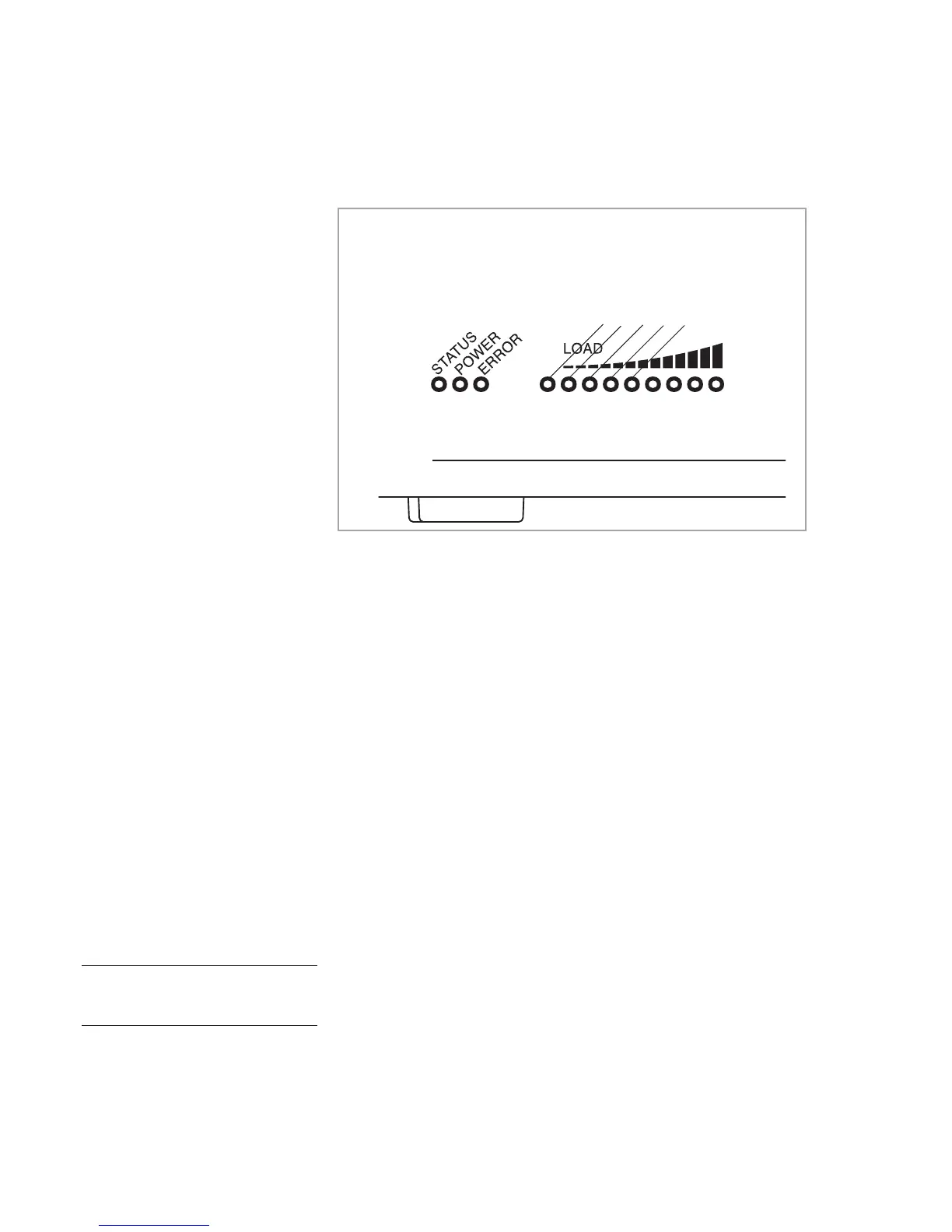

If after this process the red LED ERROR is on, then the connected pump

was not detected. If, moreover, two of the LEDs LOAD flash alternatingly,

then a different pump was detected (long flashing intervals: detected pump;

short flashing intervals: stored pump; for pump assignments refer to Fig. 3.1).

In both cases a special acknowledgement will be necessary: while keep ing

the STOP key depressed, press the START key and release it again, there-

after release the STOP key.

Through this special acknowledgement process the user acknowledges

the change of pump and the correctness of the pump which has been

detected.

Upon delivery, the Turbo.Drive TD20

classic

has been preset to the

TURBOVAC 1100 so the special acknowledgement process will have to

be run when commissioning any other pump for the first time.

Loading...

Loading...