- 123 -

3-6. Practical Work For Heavy Repair

Item Precaution Utilities

1. Removal of

residual

refrigerant

2. Installed with

a Scharader

valve By

using the

LOKRING.

3. Vacuum

process

Pipe Cutter

Piercing Pliers

Schrader valve.

LOKRING

Vacuum pump

LOKRING

Nitrogen

cylinder

Portable

Leakage

Detector

Manometer

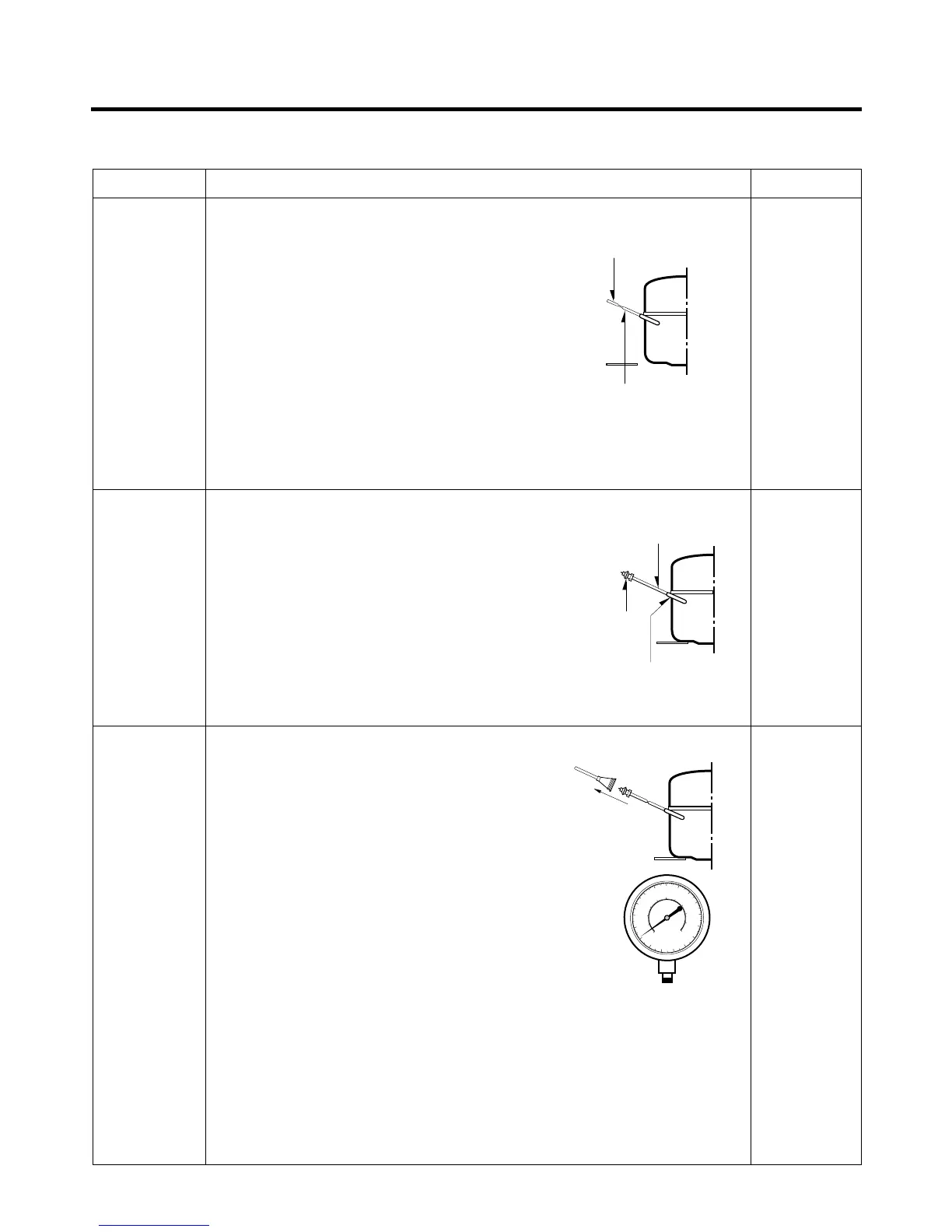

• You must discharge the residual refrigerant

(R600a) in the outdoor.

• For discharging the refrigerant R600a,

break the narrow portion of tube extension

by hand or with a pipe cutter as shown in

Figure.

• Leave if for 30~60min in outside to

stabilize the pressure with ambient.

• Check the pressure by piercing the dryer

part with pierching pliers. If the refrigerant

is not completely discharged, let the

refrigerator alone for more 30min in

outside.

• After the refrigerant is completely

discharged, repair any defective parts

and replace the dryer. At any case you

must use the LOKRING for connecting or

replacing any part in the cycle (No Fire,

No Welding).

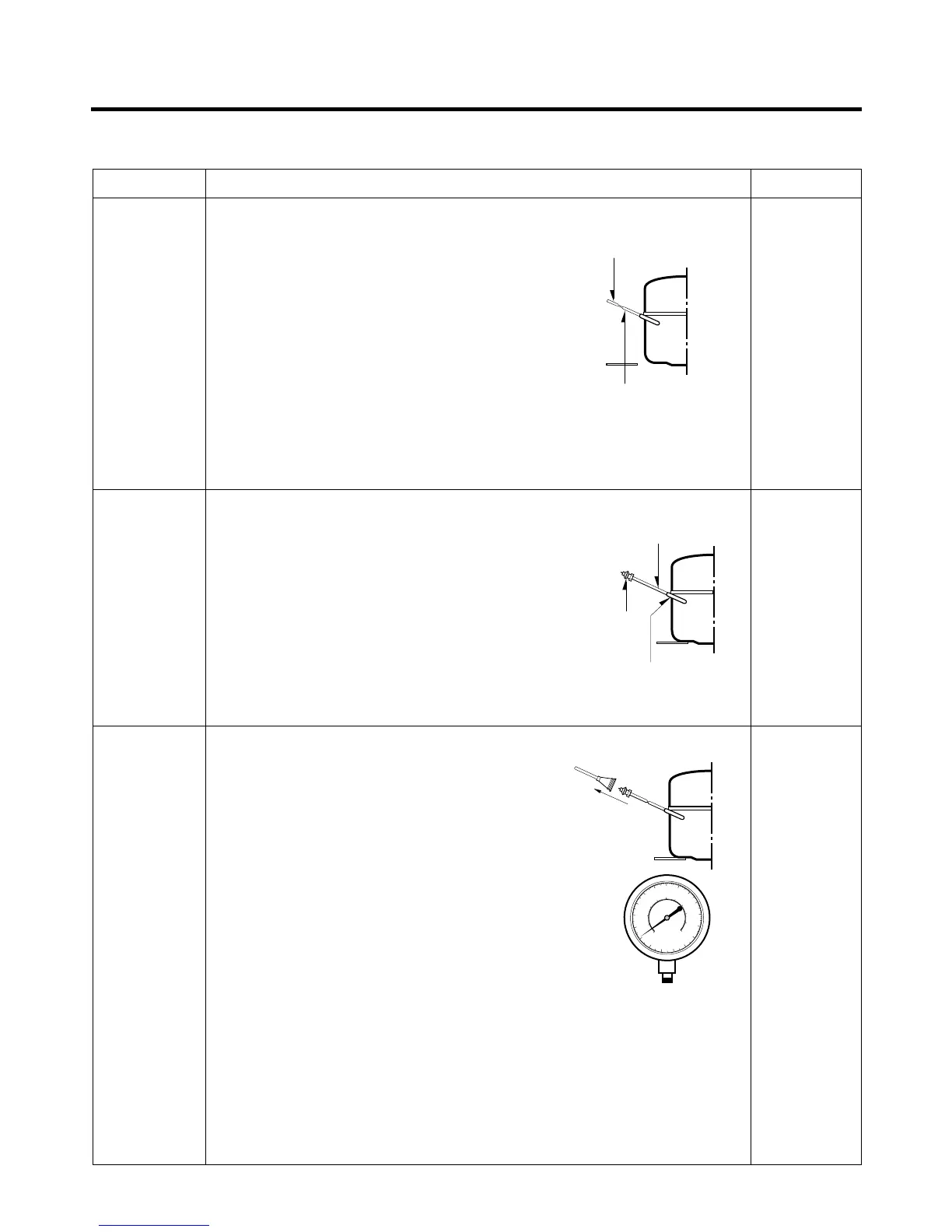

• Connect the Schrader valve to pump with

the coupler. And then turn the pump on

for vacuum state.

• Let the pump run until the low-pressure

gauge indicates the vacuum (gauge

pressure 0, absolute pressure - 1atm or -

760mmHg).

• Recommended vacuum time is 30 min.

• Charge the N

2 gas in order to check for

leakage from welding points and the

LOKRING.

• If leakages are found, repair the defects

and repeat the vacuum process.

TROUBLE DIAGNOSIS

Loading...

Loading...