Component Operation and Maintenance 41

6.4.1 Suction Pressure

Suction pressure will vary with load conditions. The low pressure switch will shut the compressor

down if suction pressure falls below the cut-out setting. High suction pressure reduces the ability of

the refrigerant to cool compressor components and can result in compressor damage. Minimum (pres-

sure switch cut-out setting) and maximum (design operating) suction pressures are in Table 16.

6.4.2 Discharge Pressure

Discharge Pressure can be increased or decreased by load conditions or condenser efficiency. The high

pressure switch will shut the compressor down at its cut-out setting. Refer to Table 17.

6.4.3 Superheat

Himod units are designed for high sensible heat ratios. At design conditions, suction superheat values

in the range of 20-35°F (11-19°C) can be expected.

Superheat can be adjusted by the Thermostatic Expansion Value (TEV).

To determine superheat:

1. Measure the temperature of the suction line at the point the TEV bulb is clamped.

2. Obtain the gauge pressure at the compressor suction valve.

3. Add the estimated pressure drop between bulb location and suction valve.

4. Convert the sum of the two pressures to the equivalent temperature.

5. Subtract this temperature from the actual suction line temperature. The difference is superheat.

6.4.4 Thermostatic Expansion Valve

Operation

The thermostatic expansion valve performs one function. It keeps the evaporator supplied with

enough refrigerant to satisfy load conditions. It does not effect compressor operation.

Proper valve operation can be determined by measuring superheat. If too little refrigerant is being fed

to the evaporator, the superheat will be high; if too much refrigerant is being supplied, the superheat

will be low. The correct superheat setting is in the range of 20-35°F (11-19°C).

Adjustment

To adjust the superheat setting, proceed as follows:

1. Remove the valve cap at the bottom of the valve.

2. Turn the adjusting stem counterclockwise to lower the superheat.

3. Turn the adjusting stem clockwise to increase the superheat.

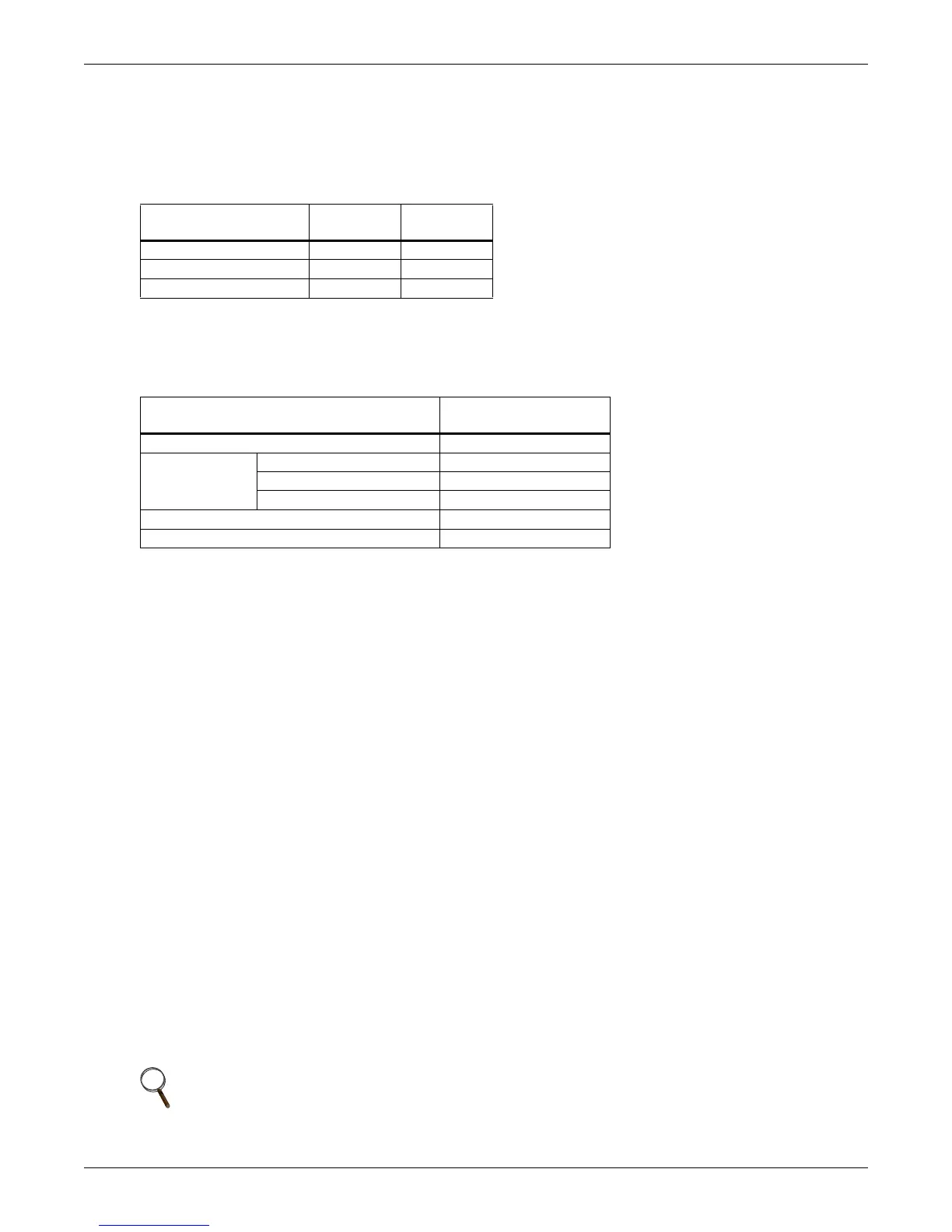

Table 16 Suction pressures

System

Minimum

PSIG (kPa)

Maximum

PSIG (kPa)

Air Cooled 20 (138) 90 (620)

Water Cooled 20 (138) 90 (620)

Glycol Cooled 20 (138) 90 (620)

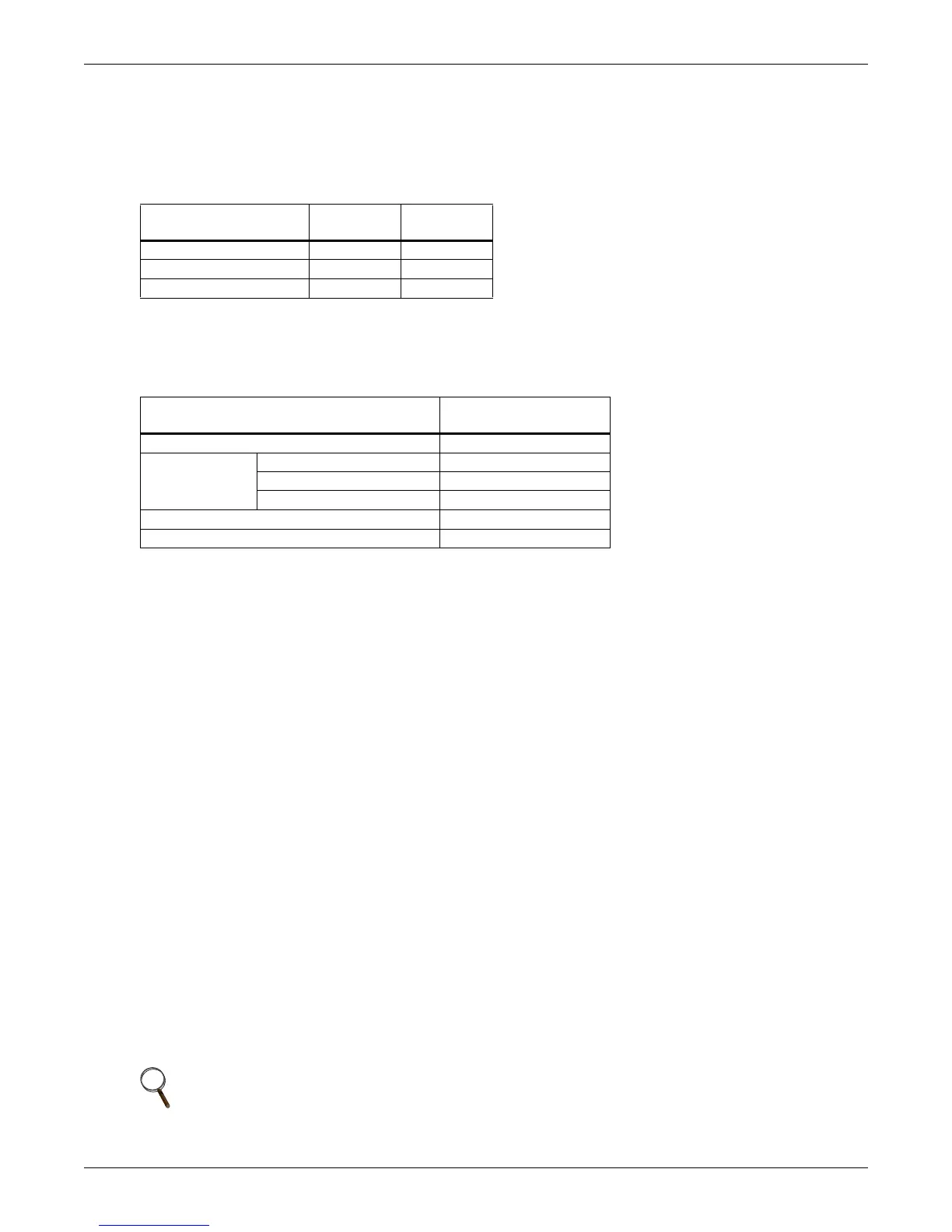

Table 17 Discharge pressures

System Design

Discharge Pressure

PSIG (kPa)

Air Cooled 260 (1795)

Glycol Cooled

65-75

°F (18-24°C) fluid 210 (1450)

85

°F (29°C) fluid 225 (1550)

115

°F (46°C) fluid 295 (2035)

Maximum 330 (2275)

High Pressure Cut-Out 360 (2482)

NOTE

Make no more than one turn of the stem at a time. As long as 30 minutes may be required for

the new balance to take place.

Loading...

Loading...