58 Troubleshooting

7.2 Other Parts/Systems - Troubleshooting

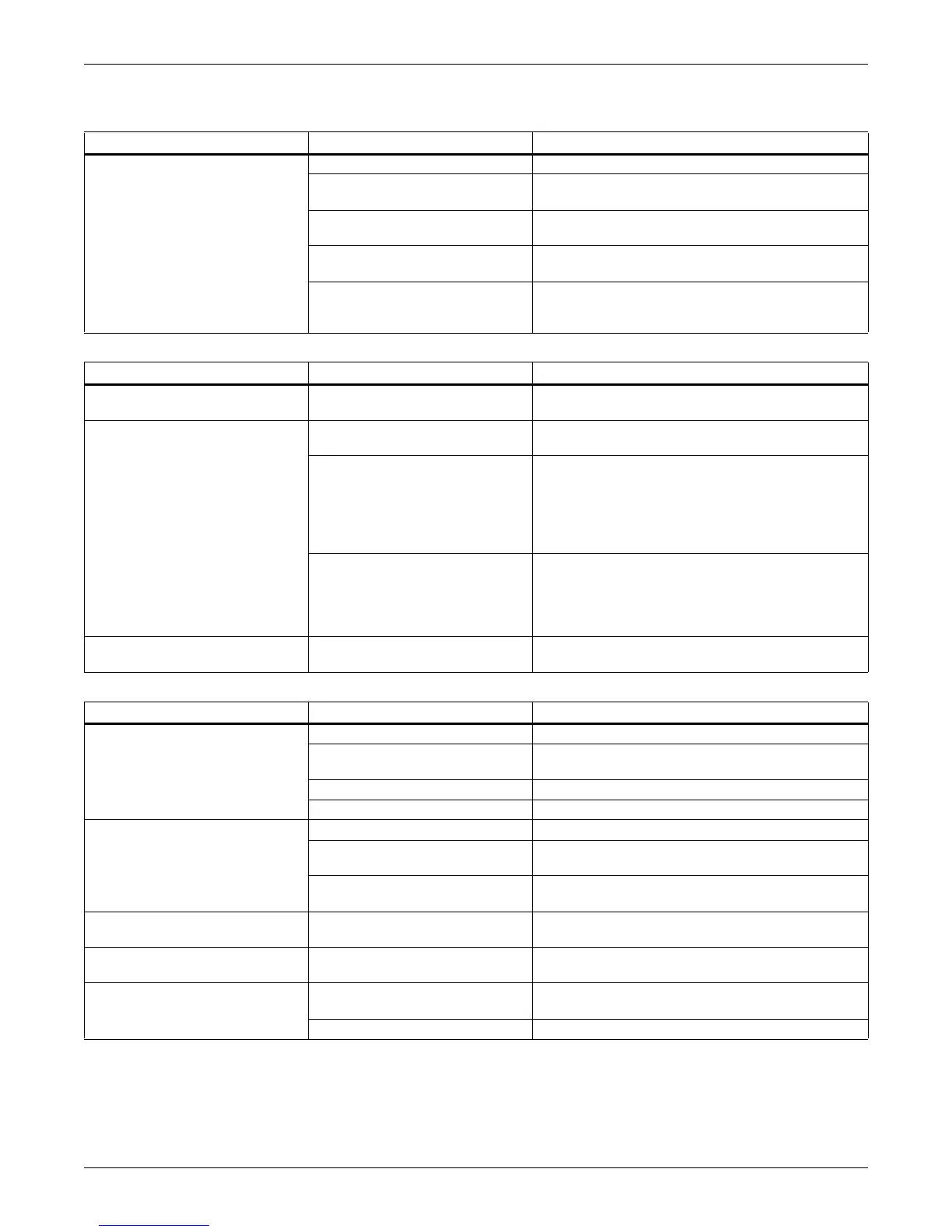

Table 19 Blower troubleshooting

Symptom Possible Cause Check or Remedy

Blower will not start

No main power Check L1, L2 and L3 for rated voltage.

Blown fuse or tripped circuit

breaker (CB)

Check fuses or CBs to main fan.

Overloads tripped

Push reset button on main fan overload. Check

amp. draw.

No output voltage from

transformer

Check for 24 VAC between P24-2 and P24-1. If no

voltage, check primary voltage.

Control fuse blown or circuit

breaker tripped

Check for 24 VAC between P4-4 and E1. If no

voltage, check for short. Replace fuse or reset

circuit breaker.

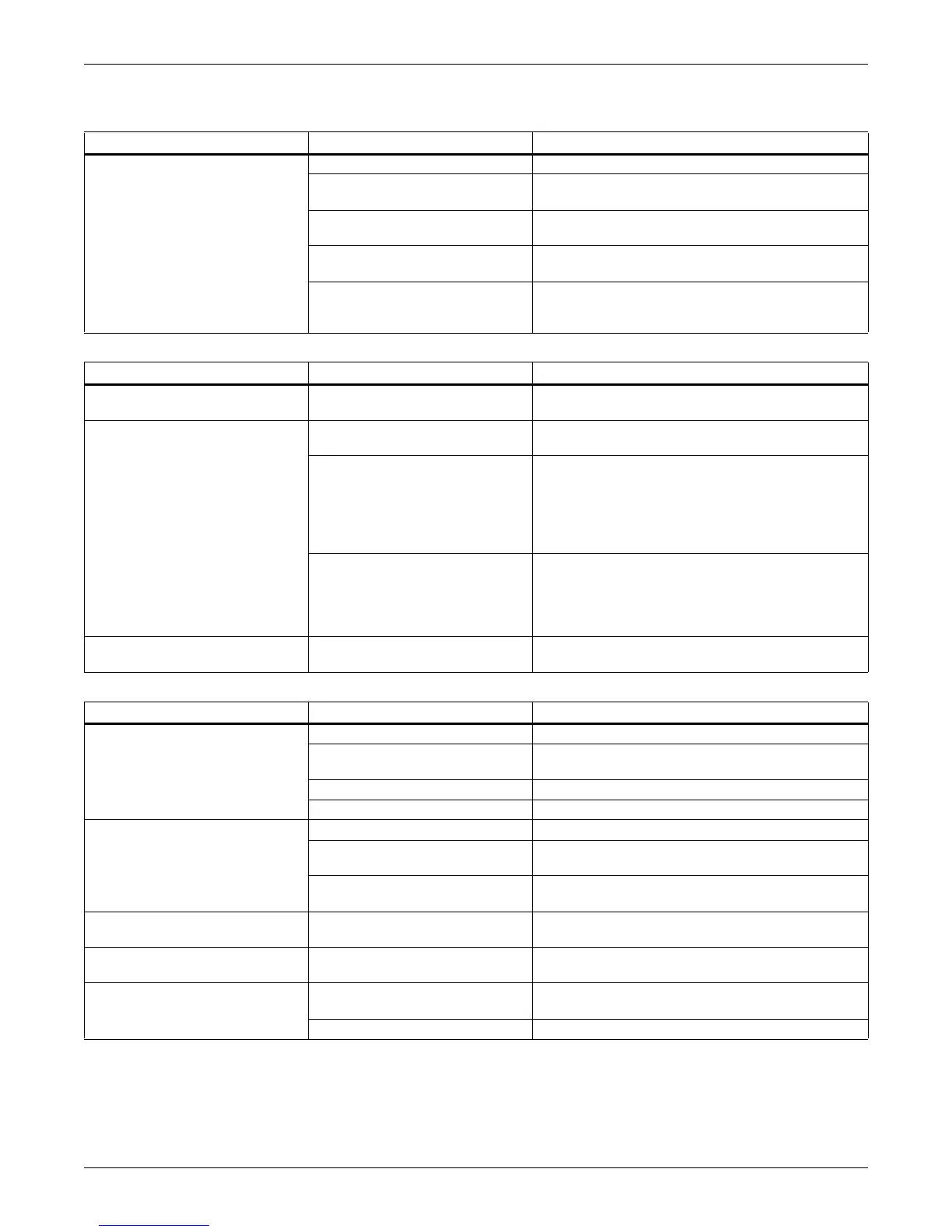

Table 20 Econ-O-Coil chilled water troubleshooting

Symptom Possible Cause Check or Remedy

Chilled water valve not opening

Motor operates but valve won’t

open

Check linkage for adjustment and be sure that it is

tight on the valve.

Modulating Motors

No 24 VAC power to motor

Check linkage for adjustment and be sure that it is

tight on the valve.

No signal from control

Check DC voltage on printed circuit board in motor.

Terminal No. 1 is grounded and No. 3 is positive.

DC voltage should vary from 0.8 to 2.0 VDC or

above as temperature control is varied below room

temperature on cooling valve or above room

temperature on heating valve.

Motor not working

Remove wires on terminal No. 1 and No. 3 from the

motor (do not short). With 24 VAC power from TR

to TR jumper terminal 1 and 2 on motor to drive

open. Remove jumper to drive closed, if motor fails

to work, replace it.

Actuator Motors No 24 VAC power to motor

Check for 24 VAC between P22-3 and P22-5

(open), or P22-1 and P22-5 (closed).

Table 21 Compressor and refrigeration system troubleshooting

Symptom Possible Cause Check or Remedy

Compressor will not start

Power off Check main switch, fuses or CBs and wiring.

Current overload open

Reset manually on units with overload option. Allow

compressor to cool for internal overloads to reset.

Loose electrical connections Tighten connections.

Compressor motor burned out Check and replace compressor if defective.

Compressor will not operate,

contactor not pulling in

No call for cooling Check monitor status.

Liquid line solenoid valve not

energizing

Hold screwdriver over solenoid and check for

magnetic field. This indicates solenoid is energized.

Low pressure switch not making

contact

Check gas pressure - manually energize low

pressure switch.

Compressor will not operate,

contact not pulling in

High pressure switch open

Reset switch. Refer to other refrigeration

troubleshooting suggestions.

Compressor contactor pulled in

but compressor will not operate

Blown fuse or tripped CB

Check for line voltage after fuses or CBs, and after

contactors.

Compressor runs for three

minutes, then stops; contactor

drops out.

Low pressure switch not closing

Check for low gas pressure. Compressor is running

on Positive Start Kit (air cooled systems only).

Liquid line solenoid not opening Check magnetic field to see if energized.

Loading...

Loading...