Page 15 of 295

IP Protection degree

The products can be cleaned as described in the following according to their IP protection stated on the product label.

The IP code specifies the protection degree provided by the enclosures. For most products, only the protection against ingress of water (second characteristic

numeral) is specified, ingress of solid foreign objects or dust (first characteristic numeral) is not specified and therefore replaced by the letter X in the code.

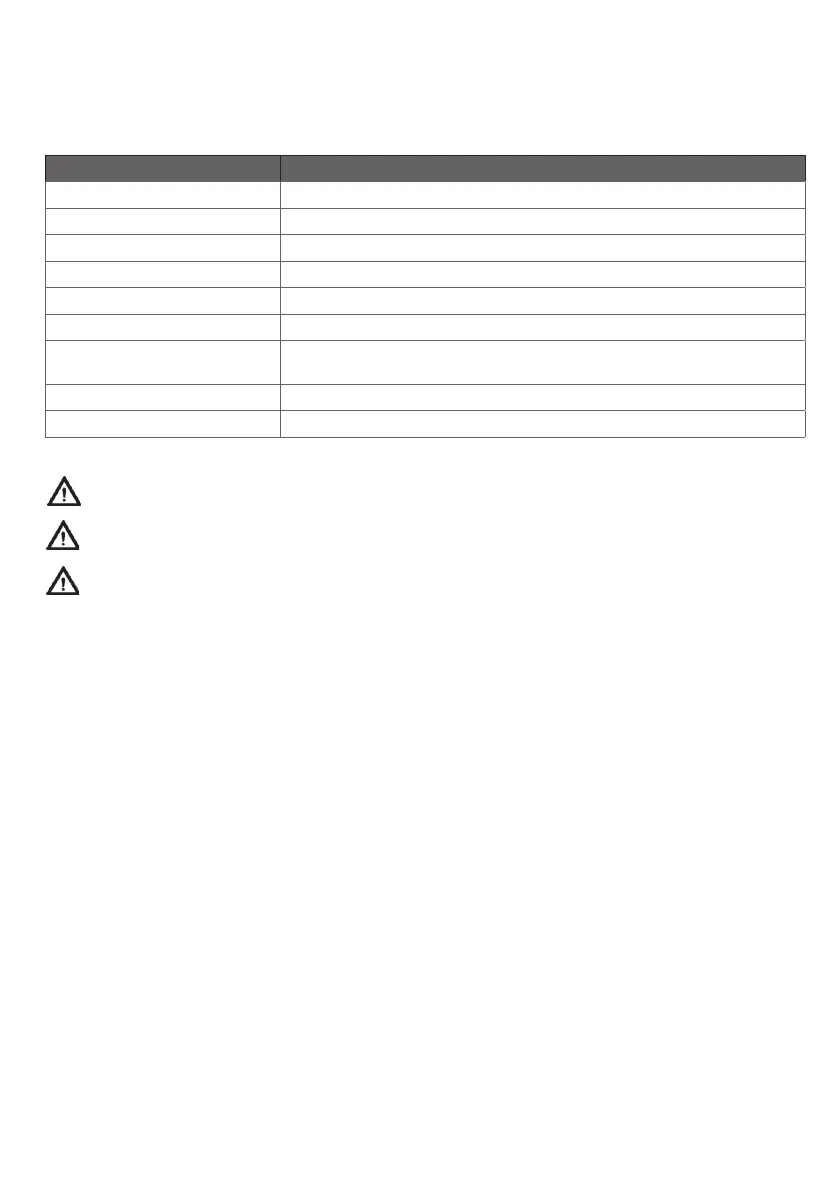

IP protection Cleaning instructions

IPX0 Clean with a damp cloth

IPX1 Clean with a damp cloth

IPX2 Clean with a damp cloth

IPX3 Clean with a damp cloth

IPX4 Clean with a damp cloth

IPX5 Wash with a brush and water, but not water under pressure

IPX6 Wash with a brush and water. The water can be under pressure, but the system must not be cleaned

directly with a high pressure cleaner. Max. 20

o

C

IPX6 Washable according to IEC 60601-2-52 Clean by the use of wash tunnels according to IEC 60601-2-52

IPX6 Washable DURA

TM

Clean by the use of wash tunnels according to IEC 60601-2-52, extended washing cycle test

To avoid degreasing of the piston rod, the actuator should be retracted to minimum stroke and without load before washing.

Warning

The systems must not be sprayed directly with a high pressure cleaner.

Warning

Interconnecting cables must remain plugged in during cleaning to prevent water ingress.

Warning

Cleaning with a steam cleaner is not permitted.

IPX6 Washable

LINAK washable products frequently undergo a fully regulated washing test.

At LINAK, “IPX6 Washable” means that the products conform only to this test.

Reference: The standard IEC 60601-2-52-2010, which includes special demands to fundamental safety and relevant functional characteristics for

hospital beds.

The demands for the washing process are described in the German “Maschinelle Dekontamination” from the organisation AK-BWA

(Arbeitskreis Bettgestell- und Wagen-Dekotaminationsanlagen).

Description: At LINAK, the washing test takes place in an instrument washing machine, which is fitted and programmed in such a way that it duplicates

the process used in a typical hospital installation for the cleaning of beds and other medical equipment.

During the test, the products are exposed to both thermal and chemical effects.

To avoid degreasing of the piston rod, the actuator should be retracted to minimum stroke and without load before washing.

Preparation: As plastic materials to a larger or lesser degree change characteristics and shape with time and climatical exposure, an ageing of the

products is carried out first. The conditions for ageing are 65 °C +/- 2 °C in normal dry air for 10 days followed by a minimum of

16 hours at room temperature before the washing process starts.

Procedure: Ageing for 10 days at 65 °C.

Rest for a minimum of 16 hours.

The washing process proceeds in the following way:

• Wash with Alkaline detergent for 2 min. with 70 °C hot water in the tank

• Rinse with neutral rinsing product for 20 sec. with 65 °C hot water in the tank

• Drying and cooling for 10 min. in open air at normal room temperature of approx. 20 °C

• The washing process is repeated 50 times

Water: Degree of hardness, no more than 5° dH and no demineralised water.

Detergents: LINAK recommends the following products:

• Sekumatic FDR or FRE from Ecolab

• Neodisher Dekonta from Dr. Weigert

• Thermosept NDR from Schülke or similar with a pH-value of 5 - 8 and in a concentration of 0.5 %

Loading...

Loading...