Electronic Control "LCM" User Manual

firmware 0.06 Rev.02 EN 7/ 15

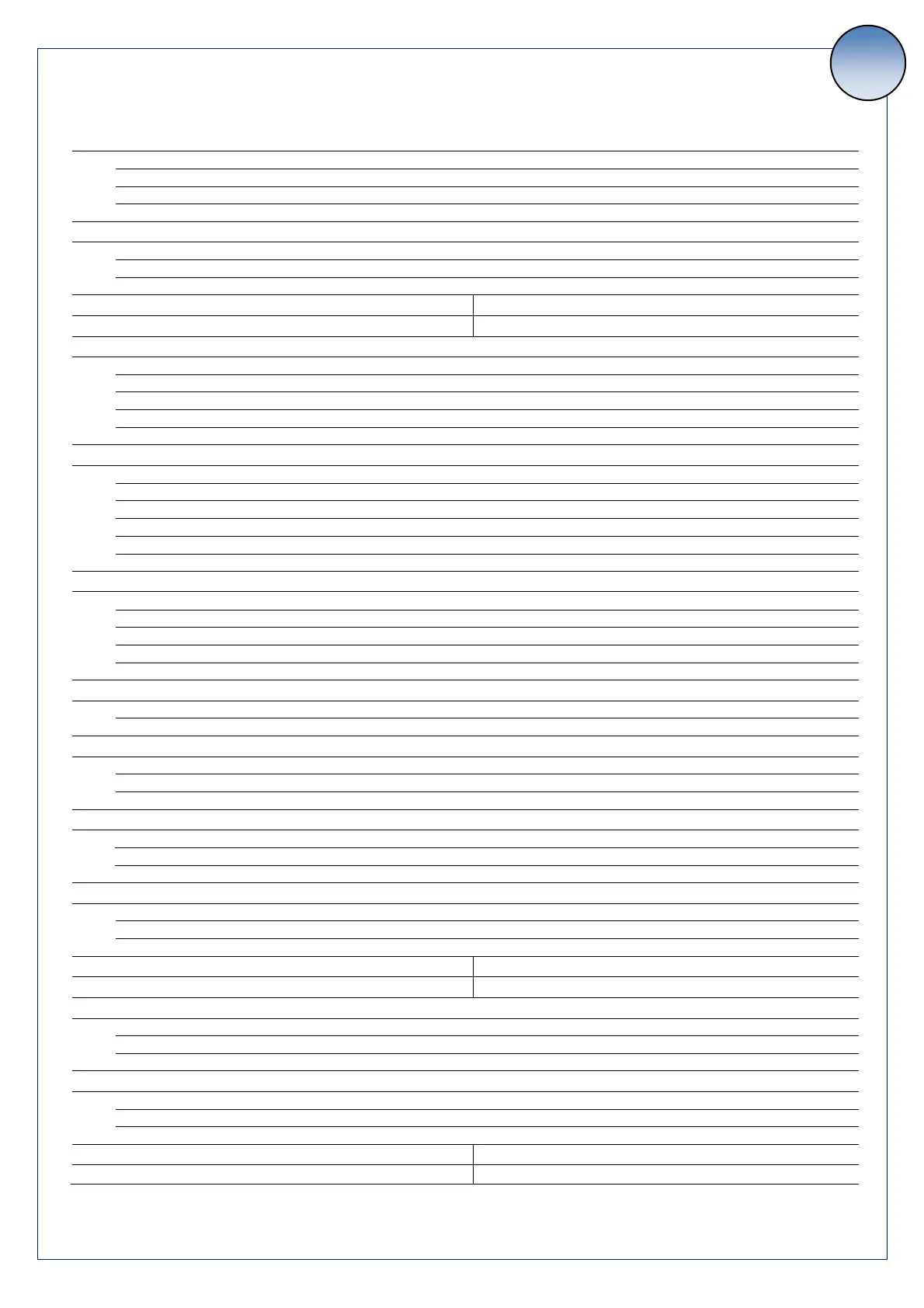

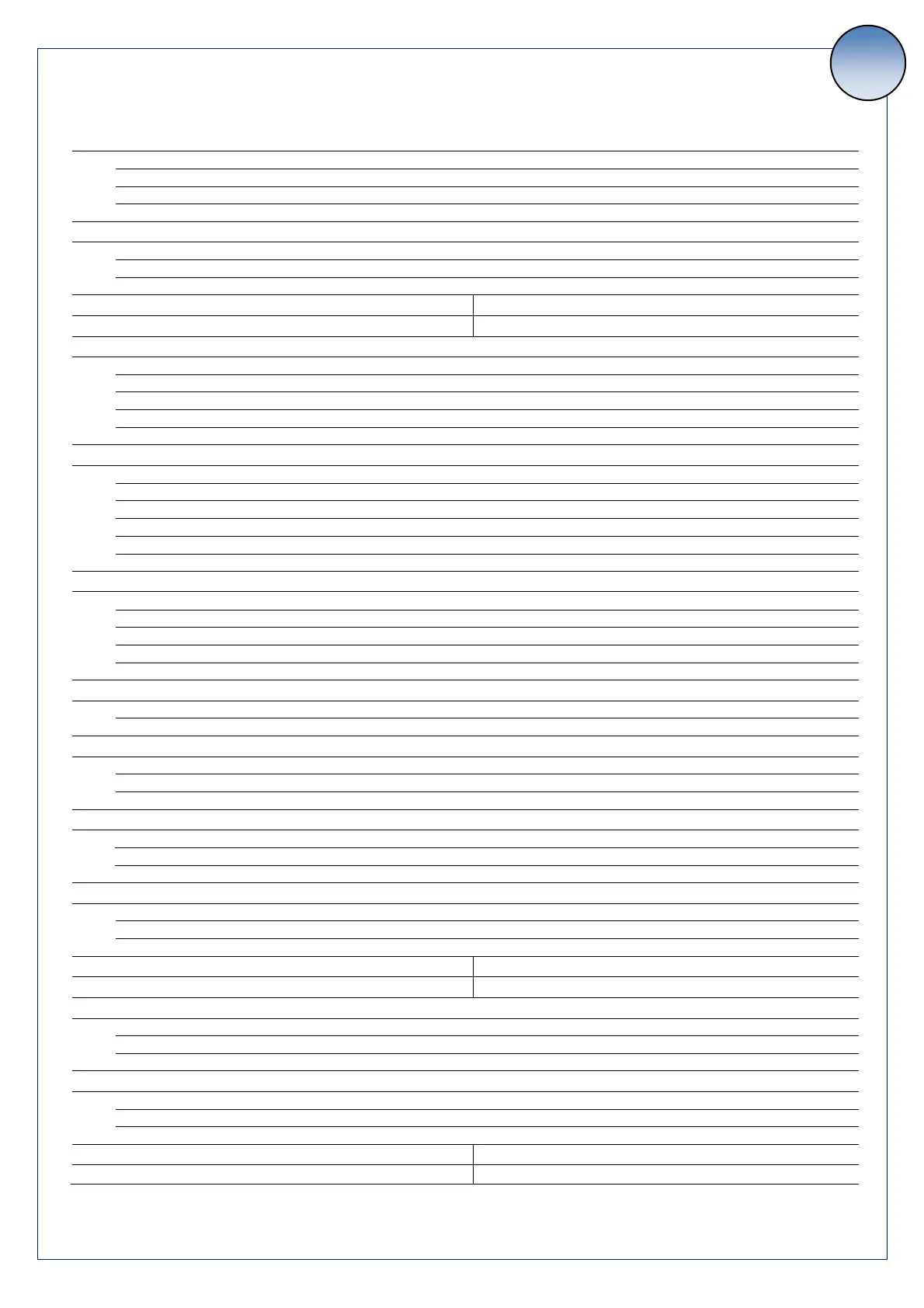

5.8. Plant configuration ()

(password) 1

0= 2 Pipes (unique changeover coil)

1= 2 Pipes + Heater (cooling coil + electrical post heater)

2*= 4 Pipes (cooling coil + heating coil)

3= 4 Pipes + Heater (cooling coil + heating coil + electrical post heater)

(Post heating valve enable AO3)

(Inverter fan enable)

(Air flow control) reboot the controller after setting

2=Supply and exhaust pressure, 2 Probes (500Pa)

3=Supply air pressure (500Pa)

4= PIR (occupant sensor) + Temperature

1= Dehumidification by digital input

2= Dehumidification by analog input

3= Humidification by digital input

4= Humidification by anlog input

5= Dehumidification /summer) - humidification (wintyer) by analogl input

(Mixing damper enable)

1= ON (with mixing dampers only)

2= CO2 digital sensor + ON-OFF dampers (DO1)

3= CO2 analog sensor + modulating dampers (AO3)

(Regulation probe)

1* = Display (SKW keyboard) or return air

(Room regulation probe)

0= Display (SKW keyboard AIR1)

1= Display clamps (SKW keyboard AIR2)

2*= AI5 (return air probe)

(Remote summer / winter changeover enable)

(Fire alarm managment)

0*= Off, in case of fire alarm the unit is completely stopped

1= On, in case of fire alarm the dampers are open and the fans run at max speed.

2= Available only with Fanl= yes: in case of fire alarm the dampers are open and only the return fans runs at max speed.

(Water coil antifreeze sensor enable)

(Modbus protocol address) ¹

(Modbus protocol Baudrate) ¹

(Modbus protocol parity) ¹

(Alarm history reset)

* Default value

¹ To apply the changes protocol reboot the controller

Loading...

Loading...