Maintenance Instruction

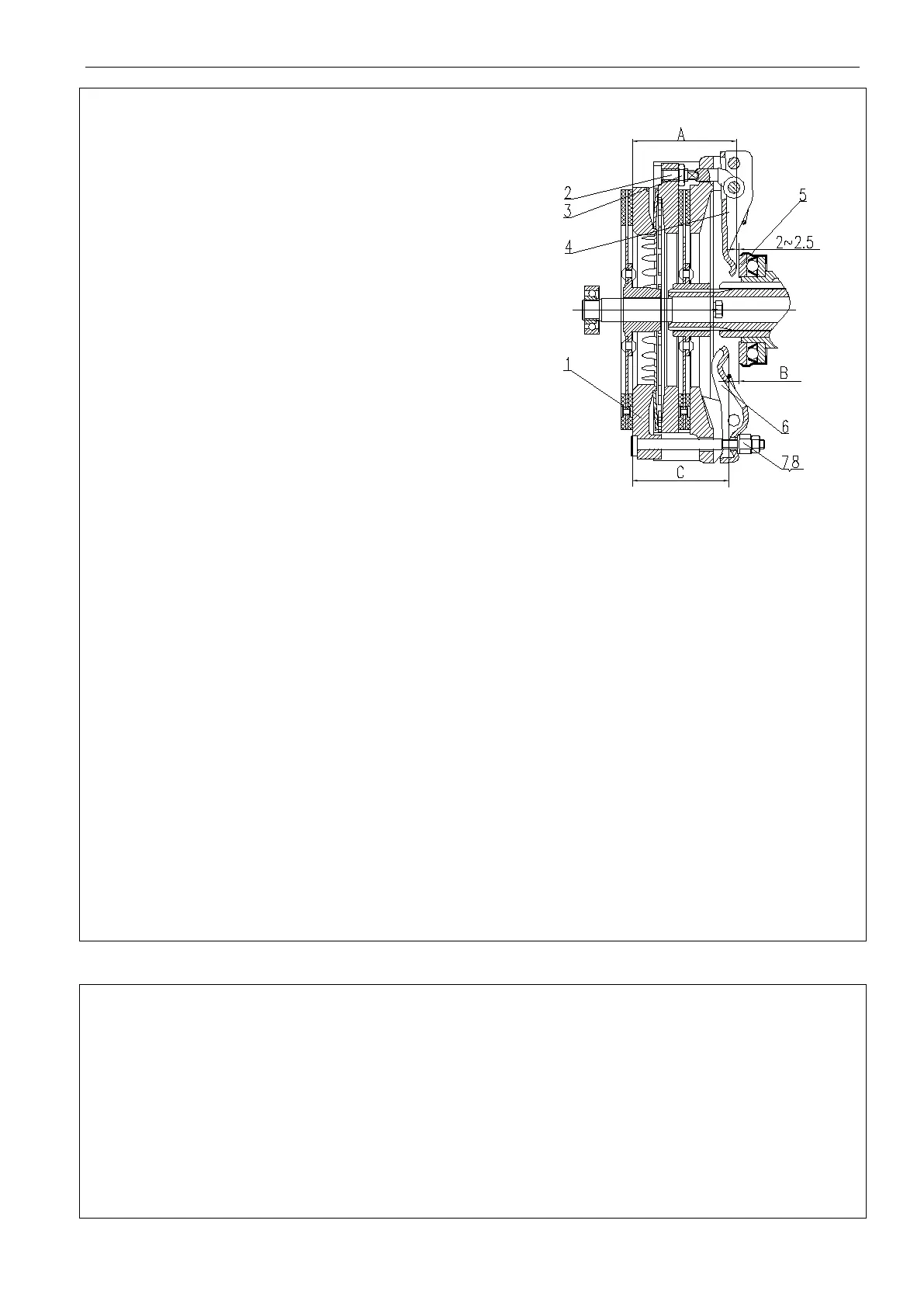

5.2.2 Clutch adjustment (double-acting)

To ensure the normal work of clutch, the clearance between

the release lever 4 working face of main clutch and end face

of release bearing 5 should be kept within(2~2.5)mm. For

25-28hp model, the clearance between the end-

face of

release lever 6 of auxiliary clutch and release bearing 5

shall be B=(10~10.5)mm (10.5-11 mm for 30-32hp

models).

Continuous wear of clutch friction lining will

gradually reduce the clearance until it disappears. Therefore

check it regularly.

(1) Free travel of clutch pedal is adjusted as follows:

Firstly loosen the lock nut 3 on the adjusting screw 2 (see

fig.5-3). Then rotate the adjusting screw 2 to make sure the

working face distance between 3-main clutch release lever 4

and clutch pressure plate 1 should be (86.5

±0.2)mm (for

25-28 horsepower type), or A=(101.5+0.2)

mm ( for 30-32

horsepower type). Finally secure the lock nut3.Firstly

loosen the nut7, 8 and rotate the adjusting nut 8 to make

sure the working face distance between auxiliary clutch

release lever 6 and clutch pressure plate 1 should be

C=(78.5+0.2)mm (for 25-28 horsepower type), or C=

(93+0.2)mm ( for 30-32 horsepower type). Finally secure

the nut 8.Adjust the clutch front fork 4 (see fig.5-

ensure the free travel of clutch pedal is(20~25)mm. After

that, lock the nut 5 (see fig.5-2).

(2) Work travel of clutch pedal is adjusted as follows:

Loosen the lock nut 1(see fig.5-2) and rotate the limit screw

2 to keep the work travel of release rocker arm 3 within

(40-45) mm. Finally secure the lock nut 1.

Fig.5-3 Double-acting Clutch

1. Pressure plate 2. Adjusting screws 3. Lock nut 4. Main clutch

release lever 5. Release bearing 6. auxiliary clutch release lever

7、8. Nut

Important:

(1)

To avoid the oil droplet is contaminated on the friction lining, frequently screw out the drain plug beneath the

flywheel housing to drain the dirty oil leaked into the engine and transfer case.

If leaking is serious, please

timely troubleshoot. If necessary, use gasoline (or kerosene) to clean the friction lining.

(2)

To prevent and avoid the wear of friction lining, the clutch should be frequently maintained and adjusted. Do not

release and engage the clutch at will. When relea

sing the clutch, fast depress the clutch to floor. Never work with

clutch semi-engaged to avoid damage of clutch.

(3)

Never work with clutch poorly adjusted. This could accelerate the wear of clutch friction lining and even

burnout.

55

Loading...

Loading...