Maintenance Instruction

5.2 Clutch adjustment

5.2.1 Clutch adjustment (single-acting)

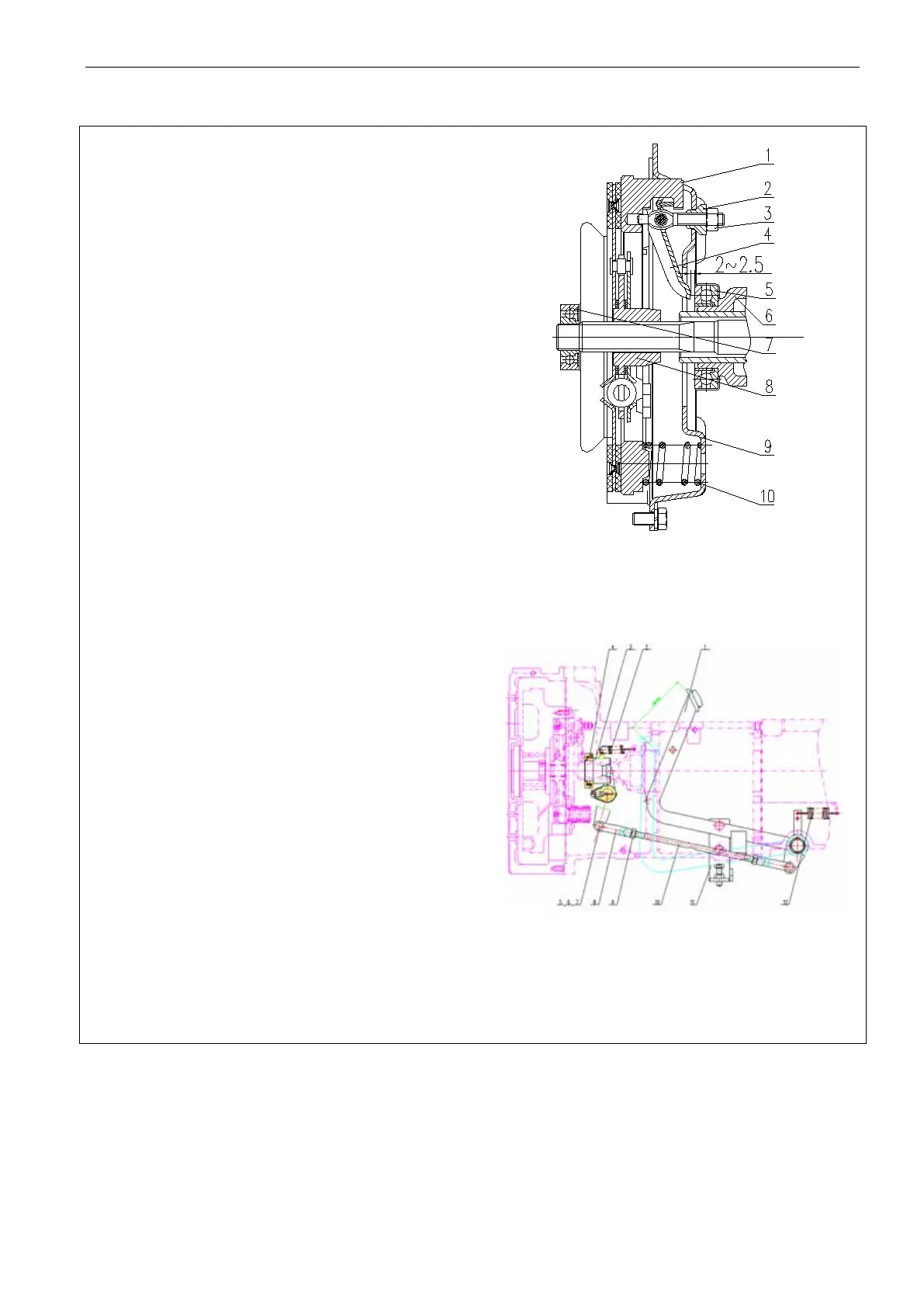

To ensure the normal work of clutch, the clearance between

the release lever 4 working face of main clutch and end face

of release bearing 5 should be kept within

(2~2.5)mm. The

clearance between the end-

face of release lever 6 of

auxiliary clutch and release bearing 5 should be kept within

B=(10~11)mm. Continuous wear of clutch friction lining

will gradually reduce the clearance until it disappears.

Therefore check it regularly.

(1) Free travel of clutch pedal is adjusted as follows:

Firstly loosen the lock nut 3 on the release lever (see

fig.5-1). Then rotate the adjusting screw 2 to make sure the

distance between working face of three release levers 4 and

clutch pressure plate 1 shall be (45±0.125)mm, finally lock

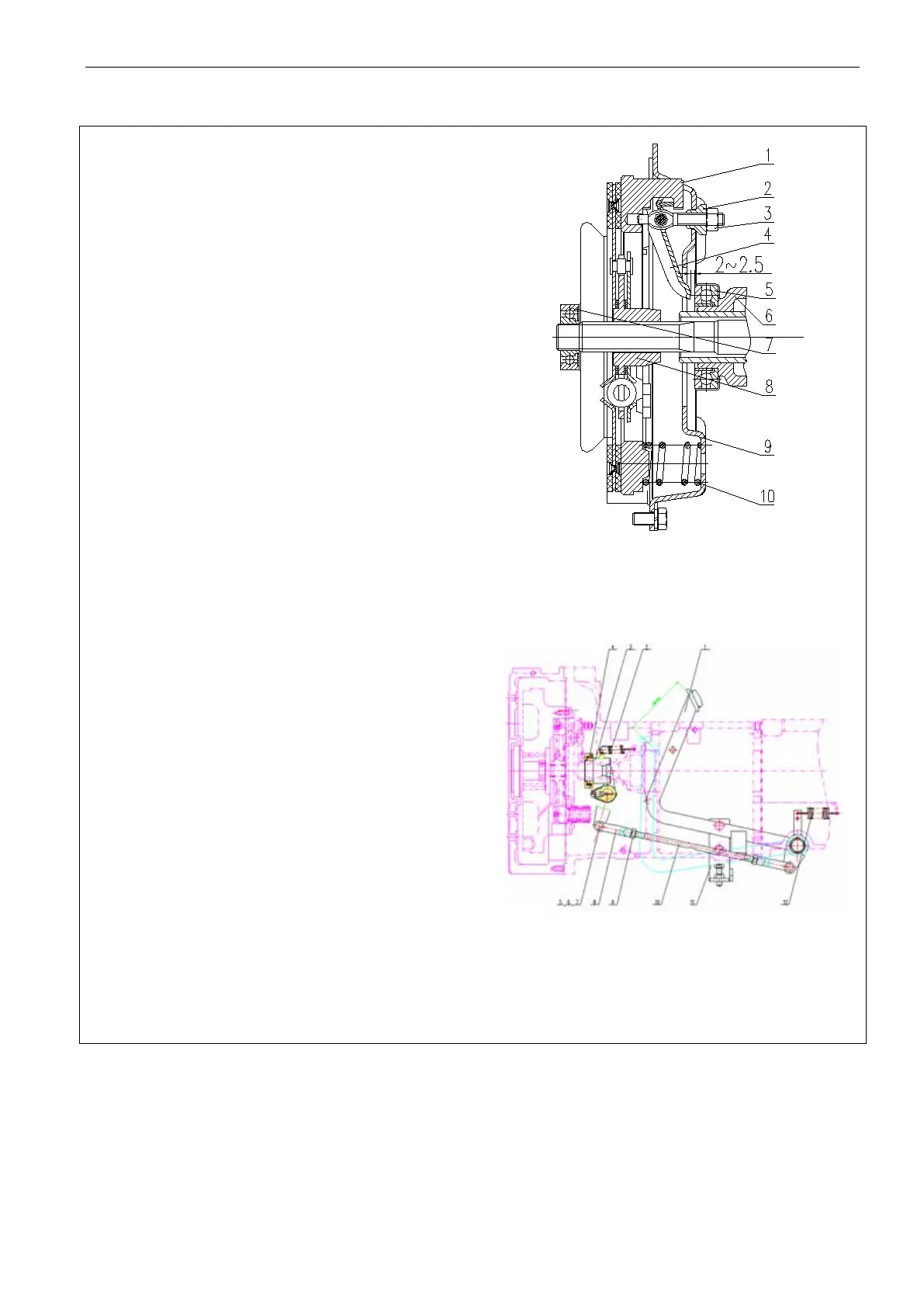

with nut 3. Adjust the clutch front fork 4 (see figure 5-2) to

ensure the free travel of clutch pedal is(4-5.5)

mm, ensure

the clearance A between working face of release lever 4 and

end face of release bearing 5 is (2-

figure); after that, lock the nut 5.

(2) Work travel of clutch pedal is adjusted as follows:

Loosen the lock nut 1(see fig.5-2, unit: mm) and rotate the

limit screw 2 to keep the work travel of release rocker arm 3

within (30-35) mm. Finally secure the lock nut 1.

Fig.5-1 Single-action clutch

1. Pressure plate 2. Adjusting nut; 3. Lock nut 4. Release lever;

5. Release bearing 6. auxiliary bearing seat; 7. Bearing; 8.

Driven plate; 9. Clutch housing; 10. Clutch spring

Fig.5-2 Clutch maneuvering system schematic

1. Pedal pressing; 2. Return spring of thrust bearing seat

3. Releasing bearing seat; 4. Release bearing; 5. Pin shaft; 6.

Split pin 7. Plain washer; 8. Front fork of lever; 9. Nut; 10.

Operation lever 11 Pedal check plate; 12. Return spring

54

Loading...

Loading...