Chapter 4 CPU Function

4 - 20

(3) Precaution

yTurning the power off and on, changes of the operation mode or operation by reset s

witch does not change the previous force on/off setting data. They remain within the

CPU module and operation is executed with the same data.

y Forced I/O data will not be cleared even in the STOP mode.

y When setting new data, disable every I/O settings using the setting data clear function

and set the new data.

Remark

-. For detailed operation, refer to the KGLWIN user’s Manual Chapter 7 ‘Force I/O setting.

4.5.3 Direct I/O operation function

This function is useful when reads an input relay’s state directly during execution of a program

and uses in the operation, or write the operation result directly to an output relay. Direct

input/output is executed by the ‘IORF’ instruction. If this instruction is used, the input/output

image area will be directly updated and applied to the continuing operations.

4.5.4 System Error History

When the system is stopped by error occurrence, the CPU stores the error occurrence time and

error code to the special data register area.

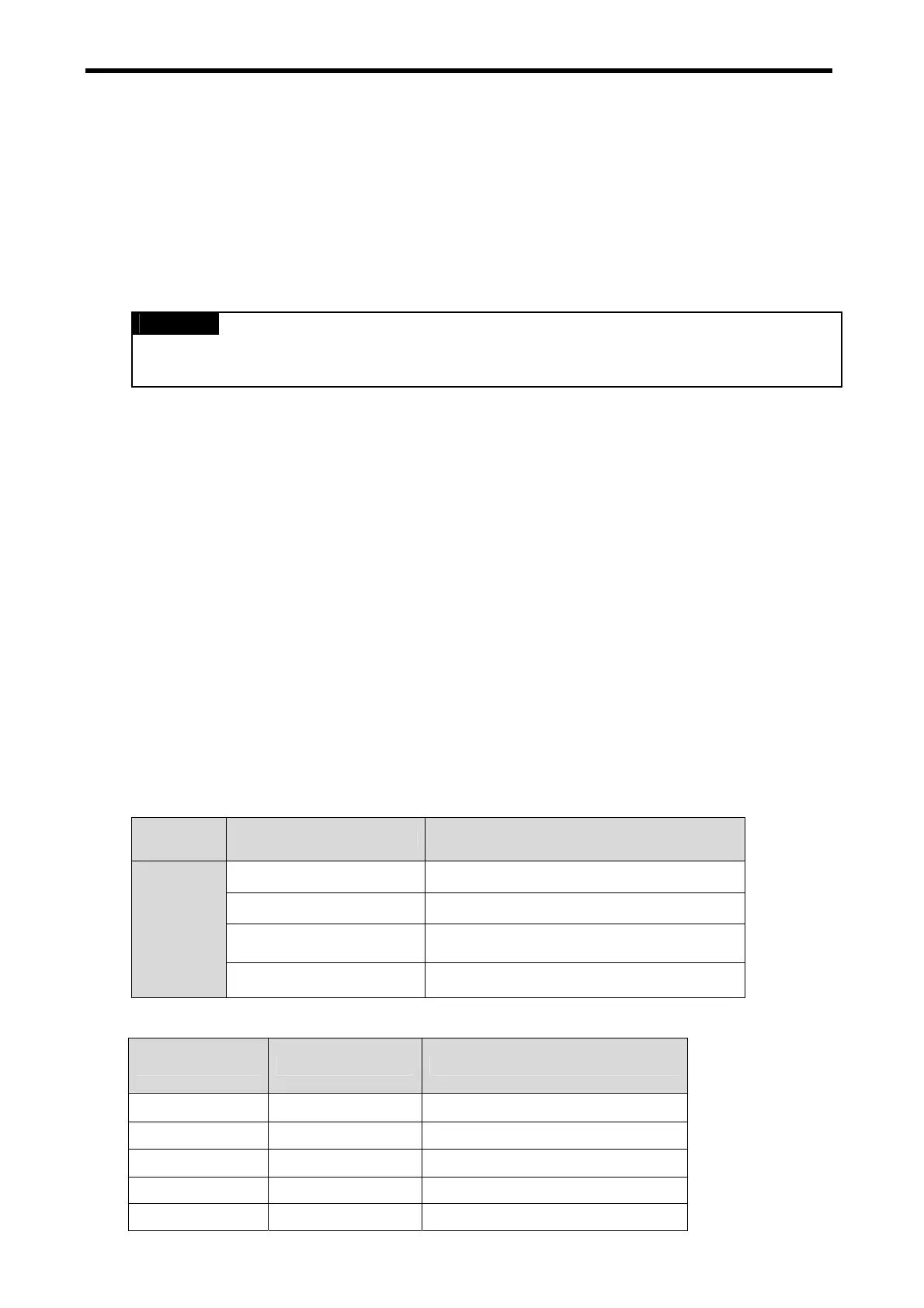

1) Special data register for Error history

The most recent 16 error occurring times and error codes are stored in the special data

register. If 17

th

error is occurred, the first error is erased and 17

th

error history is stored.

Area Error Occurred Point

D4901 ~ D4904 The 1

st

error information

D4905 ~ D4908 The 2

nd

error information

: :

Error

Stored

Device

D4961 ~ D4964 The 16

th

error information

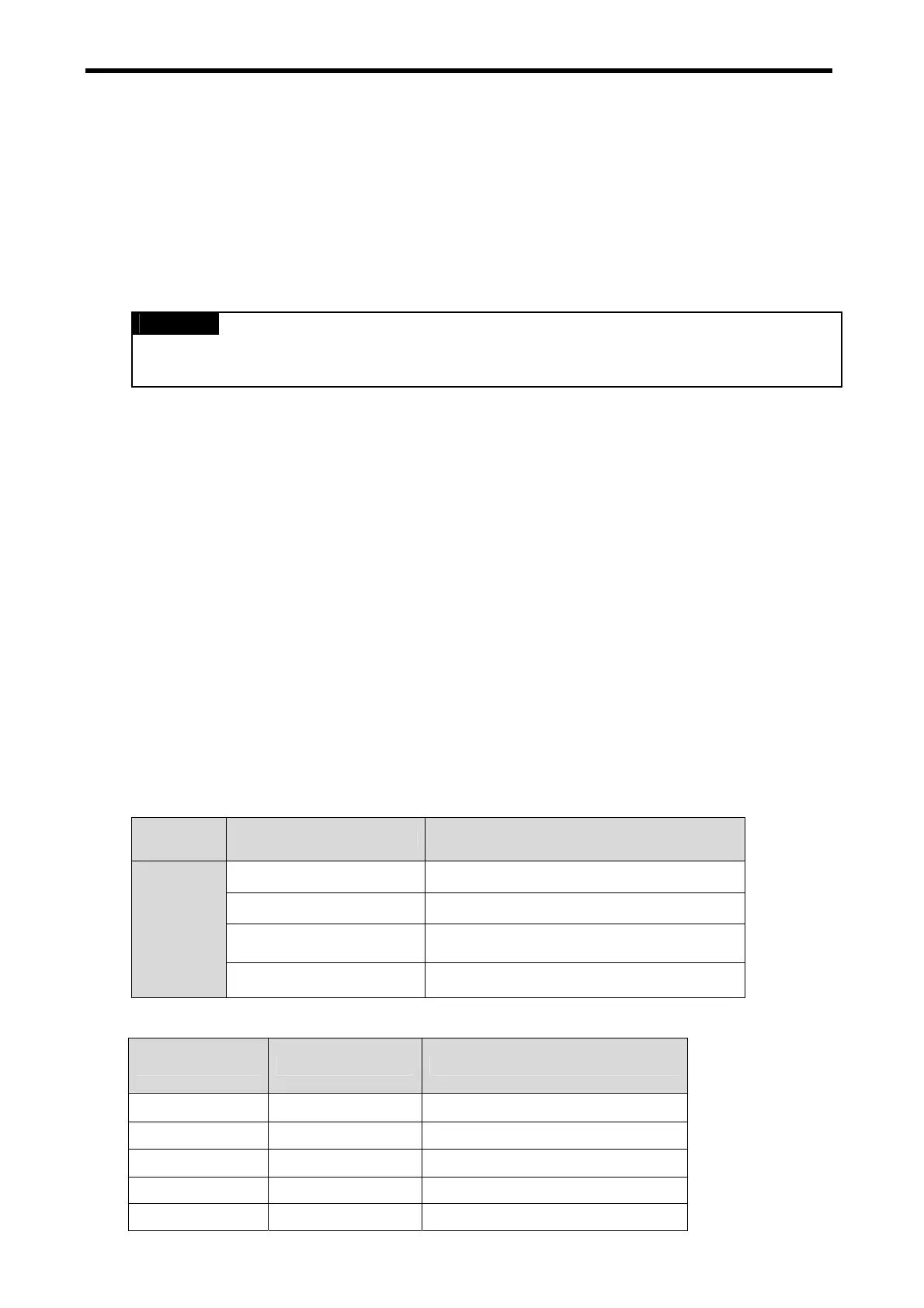

2) Description of each word

Data area Contents Description

D4900 H0001 Error occurred point

D4901 H0305 Year : 03, Month : 5

D4902 h2812 Date : 28, Hour : 12

D4903 h3030 Minute : 30, Second : 30

D4904 h0001 Error code (h0001)

Loading...

Loading...