Chapter 6 Usage of Various Functions

6-17

(2) Setting Value, Process Value

SV (set value : the designated value) and PV (process value : present value) of PID

operation have the range integer 0 ~ 4000. The range is set with the consideration of

the resolution of A/D and D/A module of PLC option card (12 bits) and offset value.

When setting the SV or PV, please be careful when converting the analog value of

control object (temperature, velocity, etc.) to digital value that are the output of A/D

convert module.

(3) Tuning method

The PLC option card for iS7 inverter perform auto-tuning operation in two methods.

One is relay response method and the other is process reaction curve method.

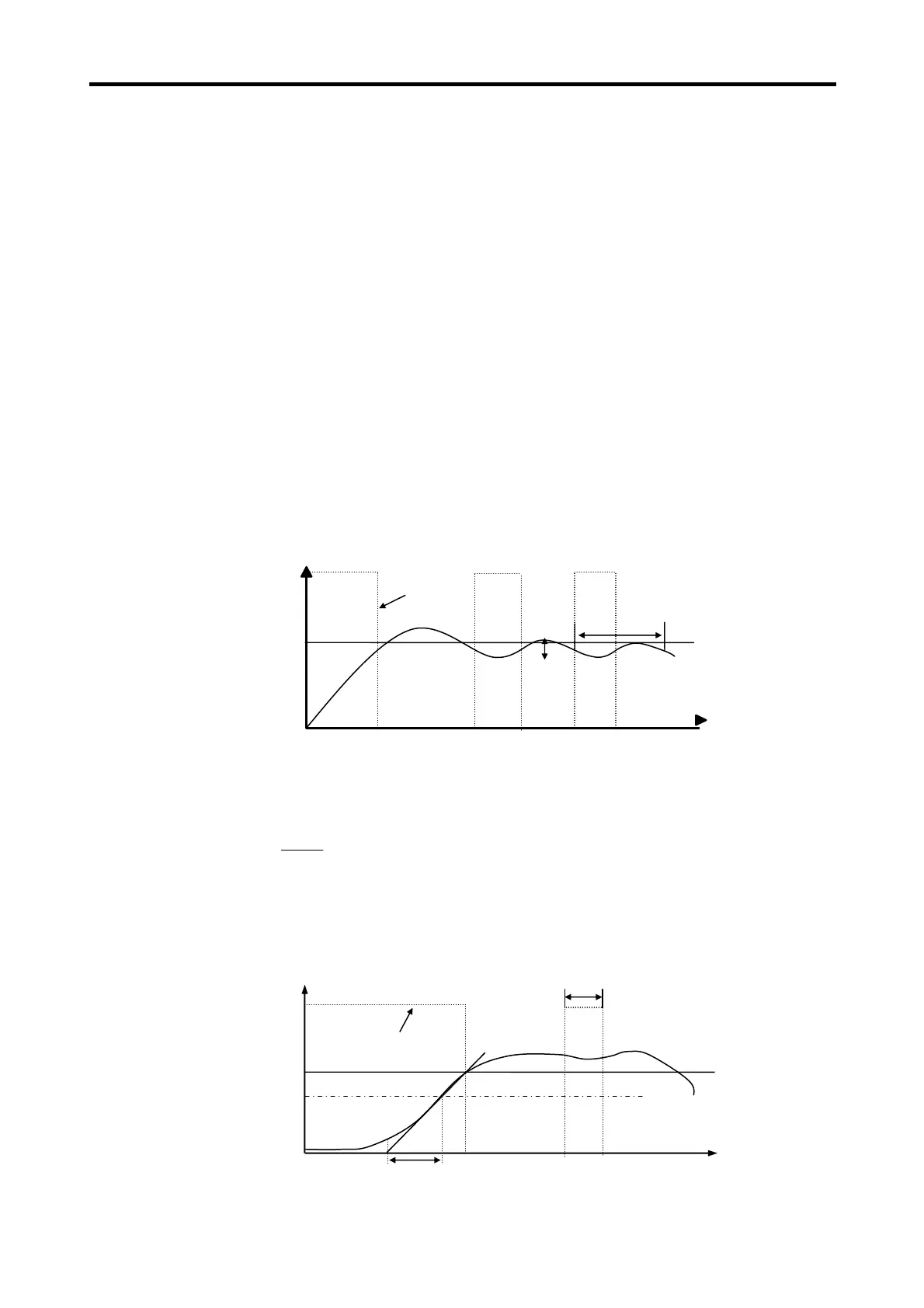

1) Relay response method

• PID parameters are obtained by On/Off operation during 1 cycle of PV variation.

• PID parameters are obtained by amplitude and period of oscillation

• The On/Off operation will occur at the SV value.

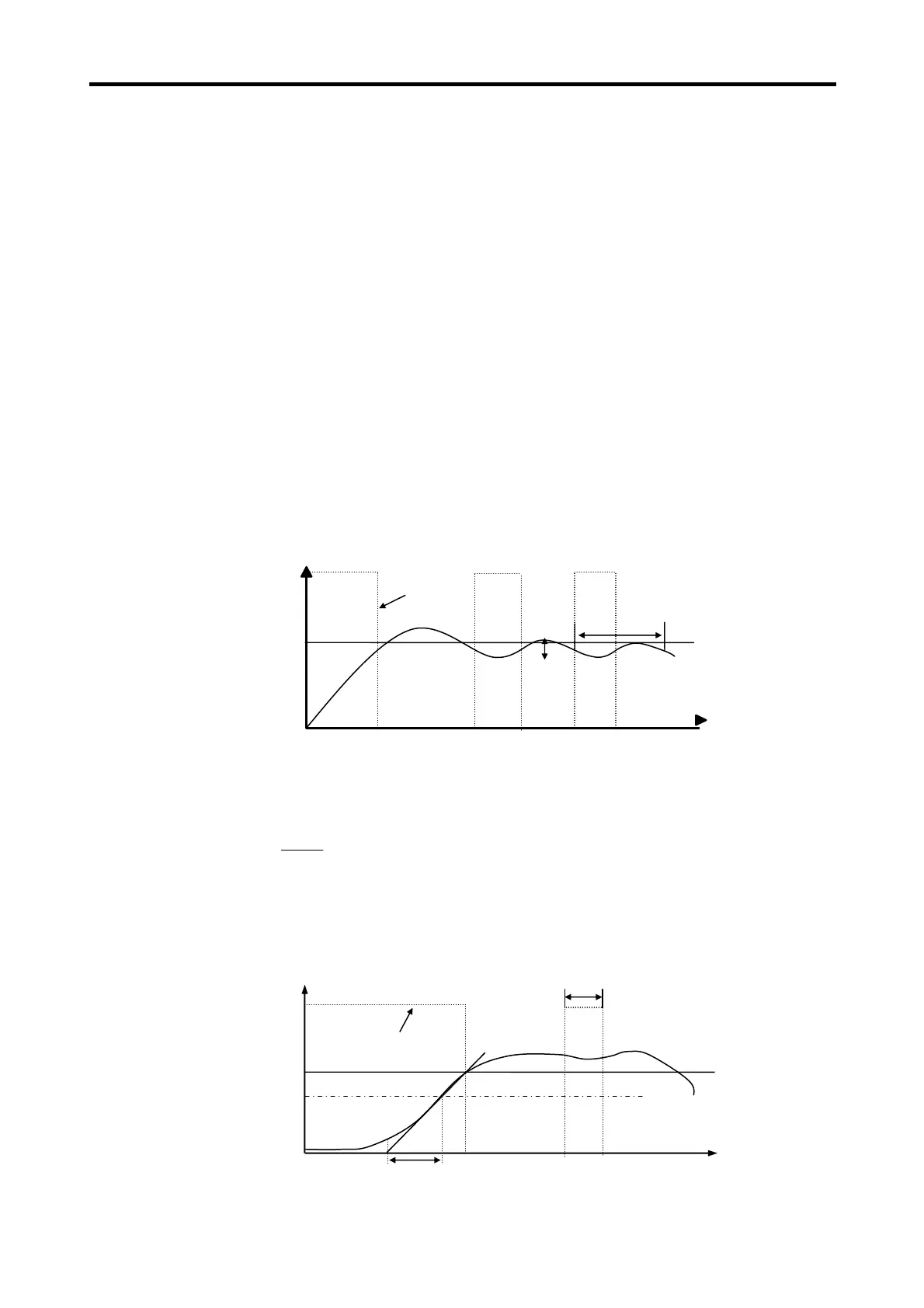

2) Process reaction curve method(PRC method).

• PID parameters are obtained by step response of process.

• It is useful fo r time 1

st

order time delay system expressed as following

1+

−

Ts

e

K

Ls

• Obtained parameters may not accurate if the process can’t approximated to 1

st

order system, In this case, use relay response method.

SV

Period

m

litude

M

80% of SV

4000

63% of SV

Time

Loading...

Loading...