Chapter 6 Usage of Various Functions

6-20

6) Example Program

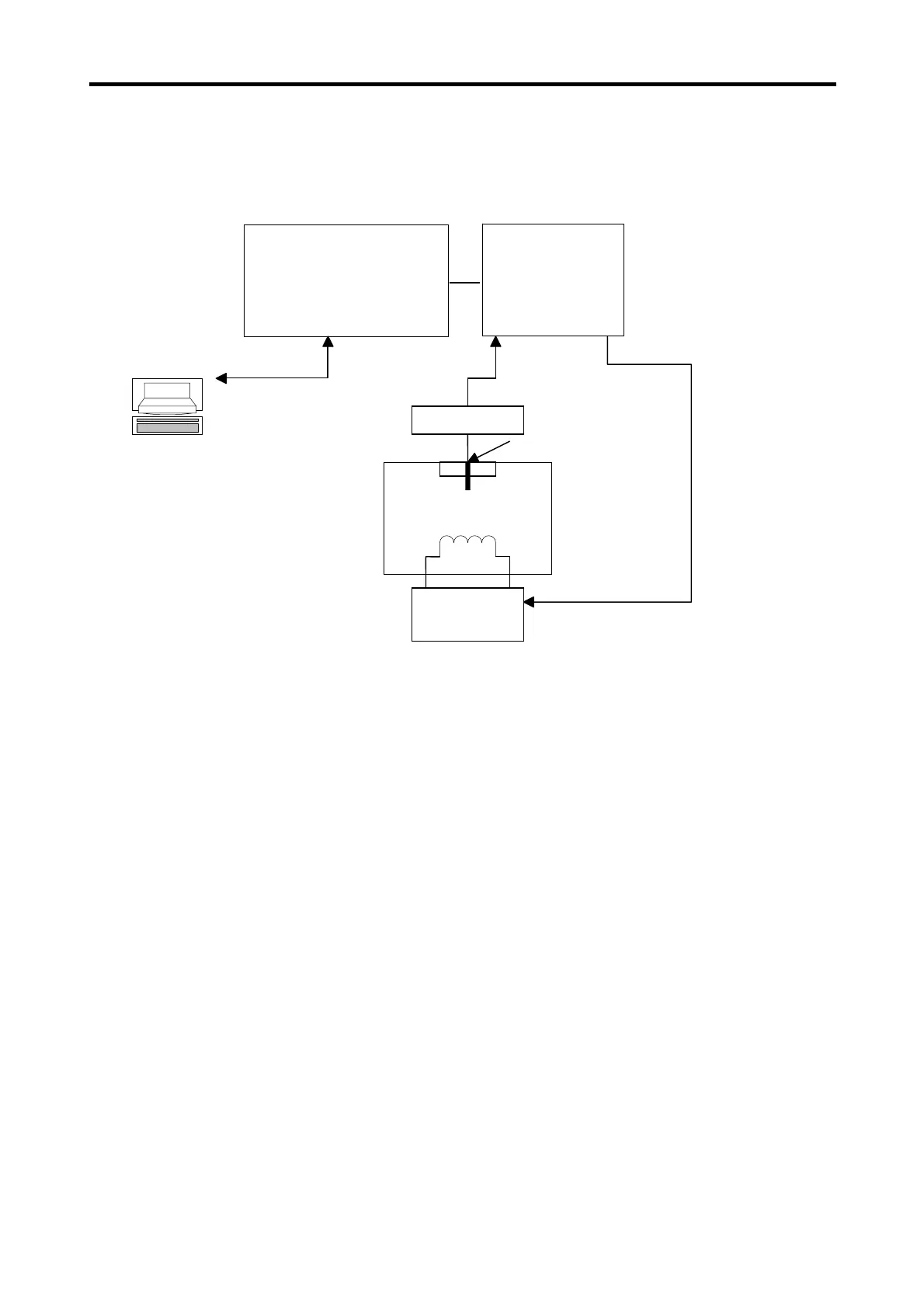

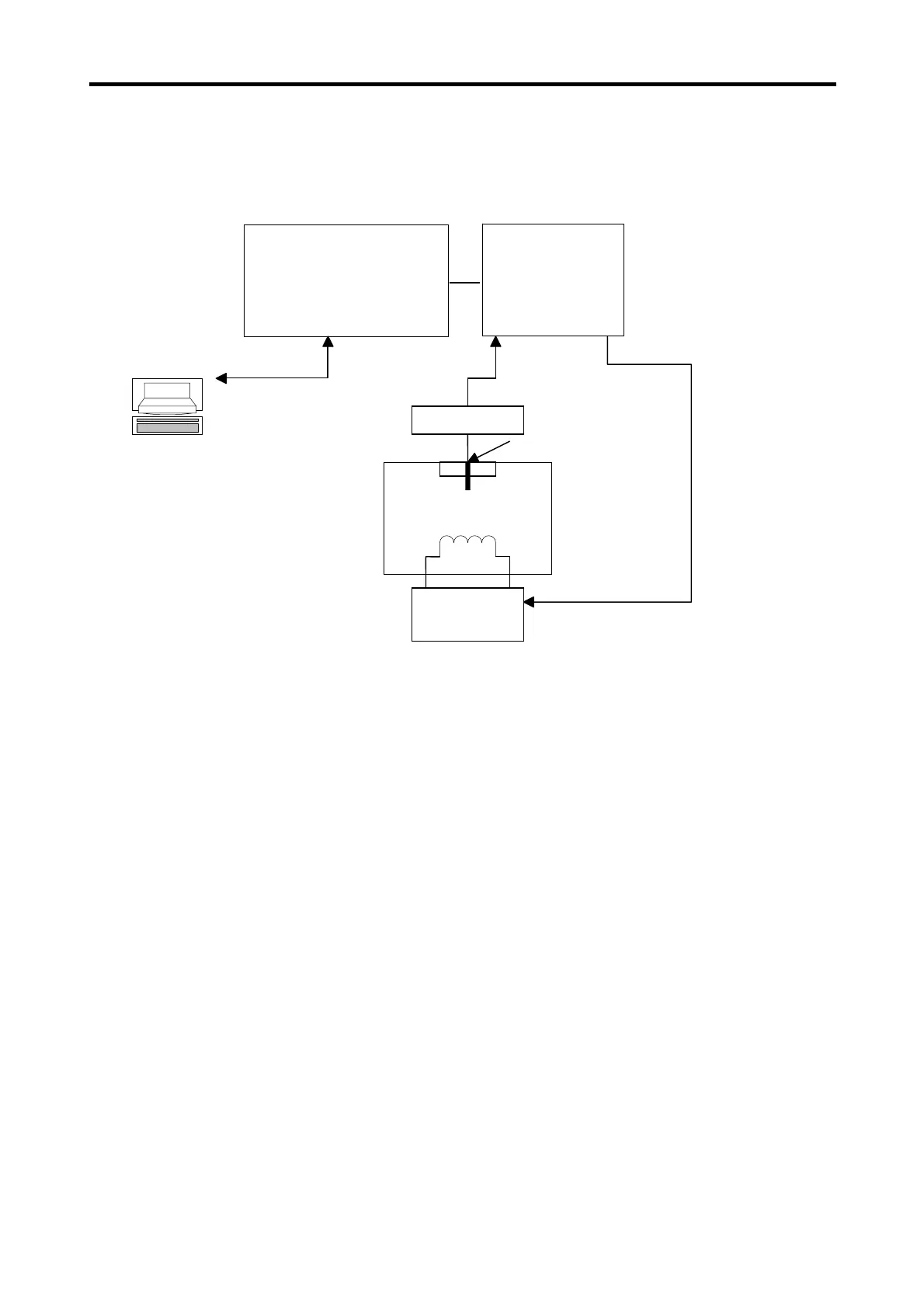

(1) System Configuration

(2) Initial Setting

a) PID Control function (parameter setting by built-in function of PLC option card)

■ Operation Scan Time: set by 1 second (Setting value = 10)

■ Operation mode: Automatic setting

■ Output Limit Value: Max. = 4000, Min. = 0

■ Manipulated Value setting: Set by 0 (Automatic operation mode)

■ High Frequency Noise Removal setting: set by 10

■ Setting Value (when Resistor Thermal Detector sensor is used)

960(60

o

C),1120(70

o

C),1280(80

o

C),1600(100

o

C)

■ Current value setting: D4980

(Temporary D area to save the current temperature measured by temperature

sensor)

■ BIAS setting: 0 (If only P control is used, input proper value other 0)

■ P,I,D Algorithm setting: Select proper algorithm.

(If PWM output is needed, select related item)

■ PWM period, Contact Setting: In case of PWM output is set, input the proper

period and output relay value.

PLC option card for

iS7 inverter series

KGL-WIN

bove V 3.4

RS-232C

TPR

Heater

Electric Oven

(0~200 ℃)

Temp. Sensor

Si

nal Converte

Present Value

(PV: DC4~20mA)

Mani

ulated Value

(MV: DC4~20mA)

Expansion I/O or

Remote I/O

Loading...

Loading...