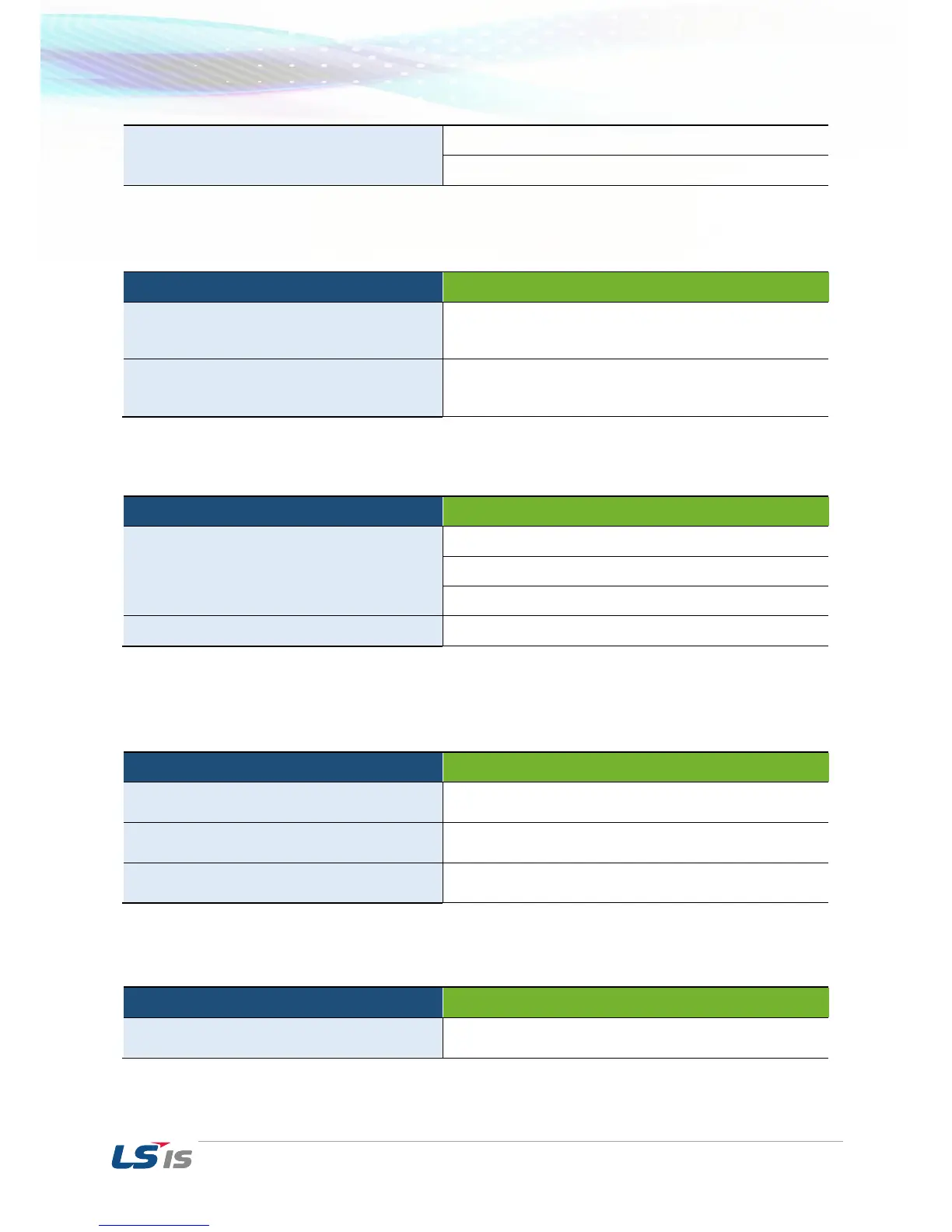

There is resonance between the motor’s natural

frequency and the inverter’s output frequency.

Slightly change the command frequency

Use the frequency jump function to avoid resonance.

The motor vibrates / hunts.

The frequency input demand was externally set

to analog command.

Change the input filter time constant if there are

interferences in the frequency command due to noise

from the analog input side.

The wiring between the motor and inverter is

too long.

Make sure that the total cable length between the inverter

and the motor is less than 150m (50m for motors rated

3.7kW and lower).

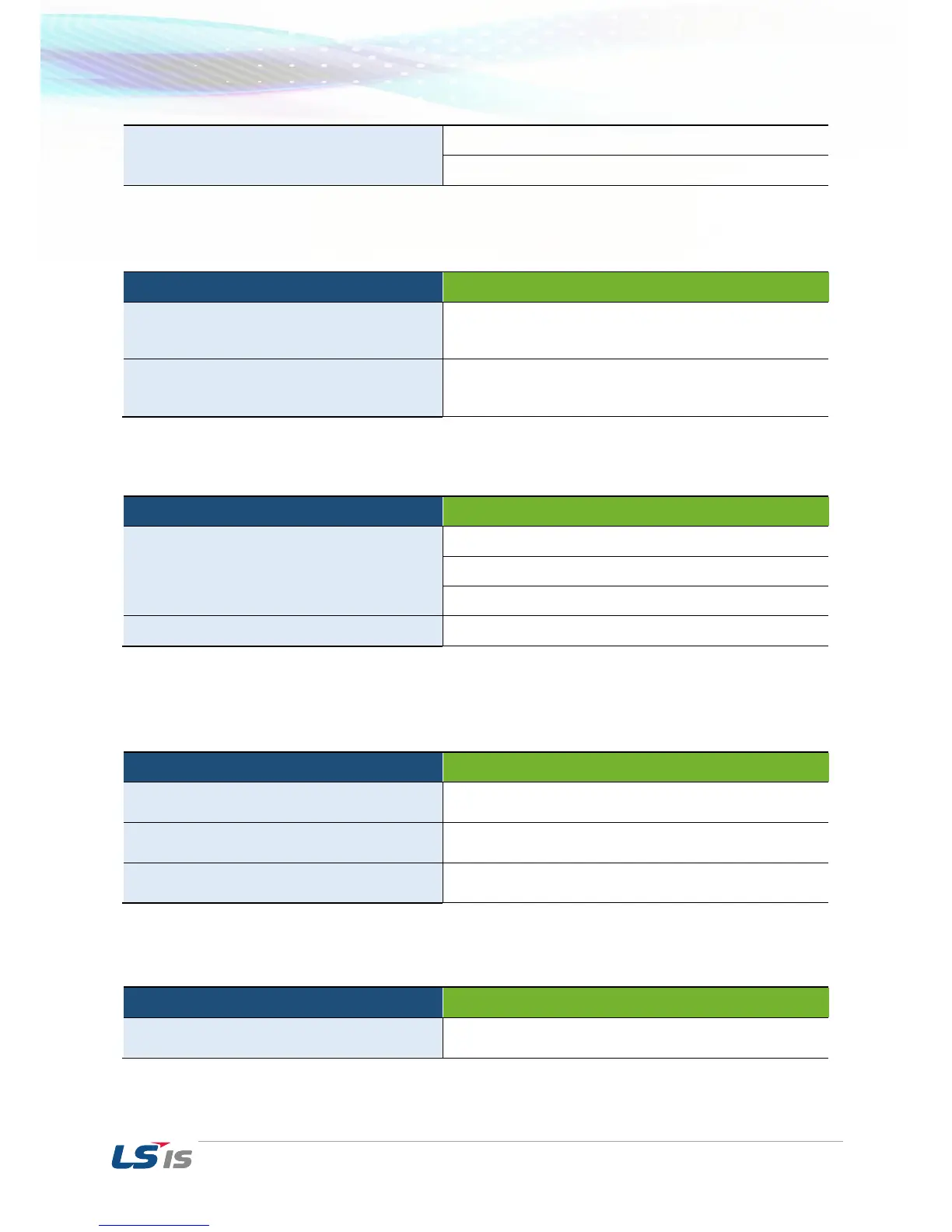

The motor does not stop completely when the inverter output stopped.

The motor cannot decelerate sufficiently due to

malfunction of the DC braking.

Adjust the DC braking parameter.

Increase the set value for DC braking current.

Increase the set value for the DC braking stopping time.

Free run stop was selected.

Change the stopping method to decelerating.

The output frequency does not reach the target frequency.

The target frequency is within the jump

frequency range.

Set the target frequency higher than the jump frequency

range.

The target frequency is higher than the upper

limit of the frequency command.

Set the upper limit of the frequency command higher than

the target frequency.

The stall prevention function is not working due

to high load.

Replace the inverter with a bigger capacity.

The cooling fan does not rotate.

The control parameter for the cooling fan is set

incorrectly.

Check the control parameter settings for the cooling fan in

ADV-64

Loading...

Loading...