2. Troubleshooting

33

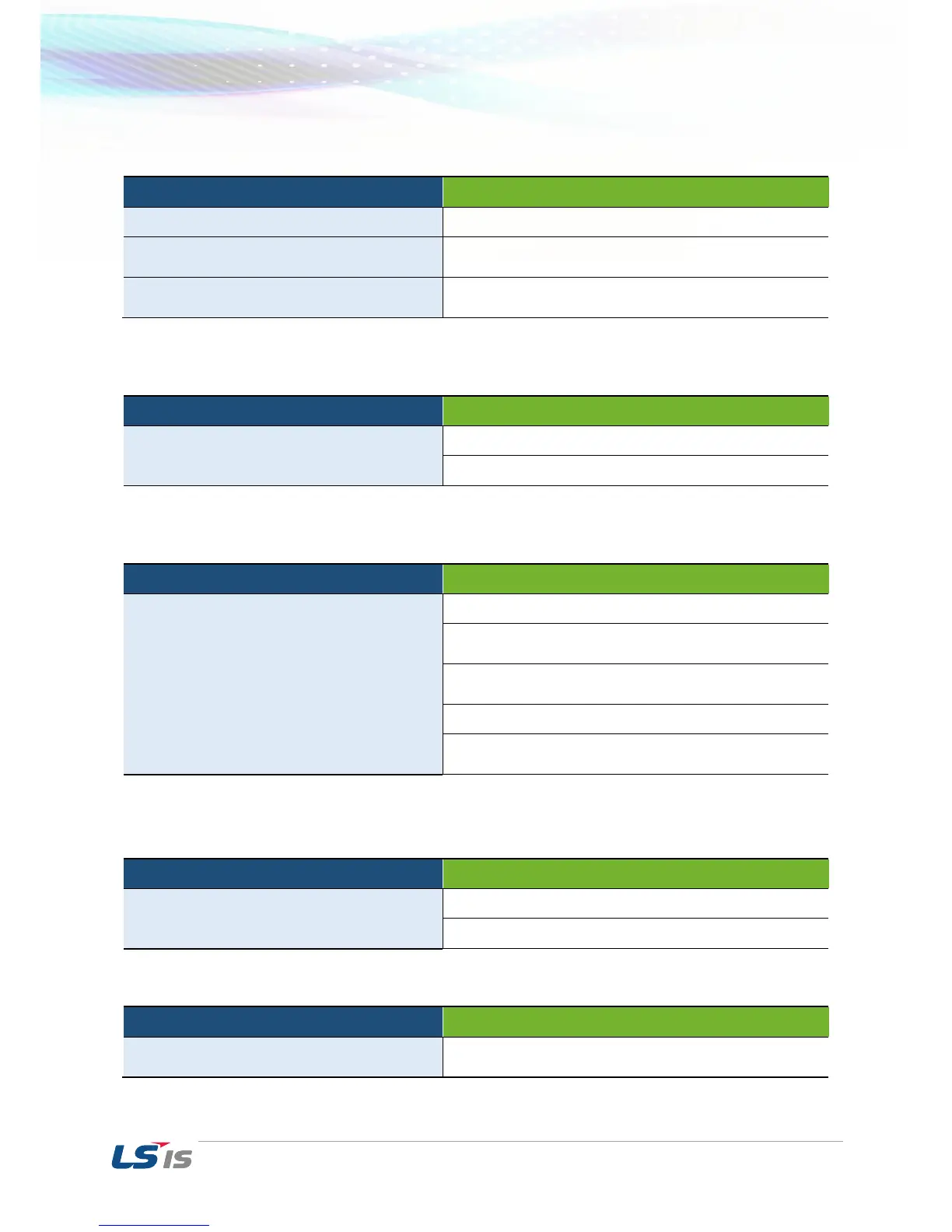

The deceleration time is too long even with the Dynamic Breaking resistor connected to the

motor.

The deceleration time is set too long.

Change the setting accordingly.

The motor torque is insufficient.

If there is no problem with motor parameters, this is due to

motor capacity. Replace the motor with a bigger capacity.

The load is higher than the internal torque limit

(based on the rated current) of the inverter..

Replace the inverter with a bigger capacity.

The control unit is not working or noise is generated when the inverter is in operation.

The switching inside the inverter caused noise.

Reduce the carrier frequency in CON-04.

Install a micro surge filer in the inverter output.

The earth leakage breaker is activated when the inverter is in operation.

The earth leakage breaker is activated due to

leaking current from the inverter.

Connect the inverter to the ground terminal.

Check the ground resistance is less than 100 Ω for 200V

and less than 10 Ω for 400V inverters.

Check the capacity of the leakage breaker and connect

properly based on the rated current of the inverter.

Reduce the carrier frequency in CON-04.

Make the cable length between the inverter and the motor

as short as possible.

The motor vibrates intensely and does not rotate normally.

The phase-to-phase voltage of 3-phase power

source is not balance.

Check the input voltage and stabilize the voltage.

Check and test the insulation of the motor.

The motor makes humming or loud noises.

There is resonance between the motor’s natural

frequency and the carrier frequency.

Reduce the carrier frequency in CON-04.

Loading...

Loading...