50

During filling of the reservoir or immediately after the

maximum level has been reached, some lubricant may be

expelled at the overflow opening. The overflow is located

on the left side of the pump where the pump base meets

the reservoir. Air possibly trapped under the follower

plate and excess lubricant shall come out at this opening.

Note: DO NOT OVERFILL: Although the automated lubrication pump is equipped with an overflow

opening; continuing to add lubricant to a reservoir which has reached its maximum fill mark may

experience some pressure build up inside the reservoir.

Note: Every automated lubrication pump male filler connector is equipped with an internal filter. When

filling of the reservoir is difficult, inspect the filter, clean or replace when necessary.

Step 6: Place the dust cap back on the

male coupler on the automated

lubrication pump and place the female

filler-pump coupler on the male

coupler on the lid of the filler pump.

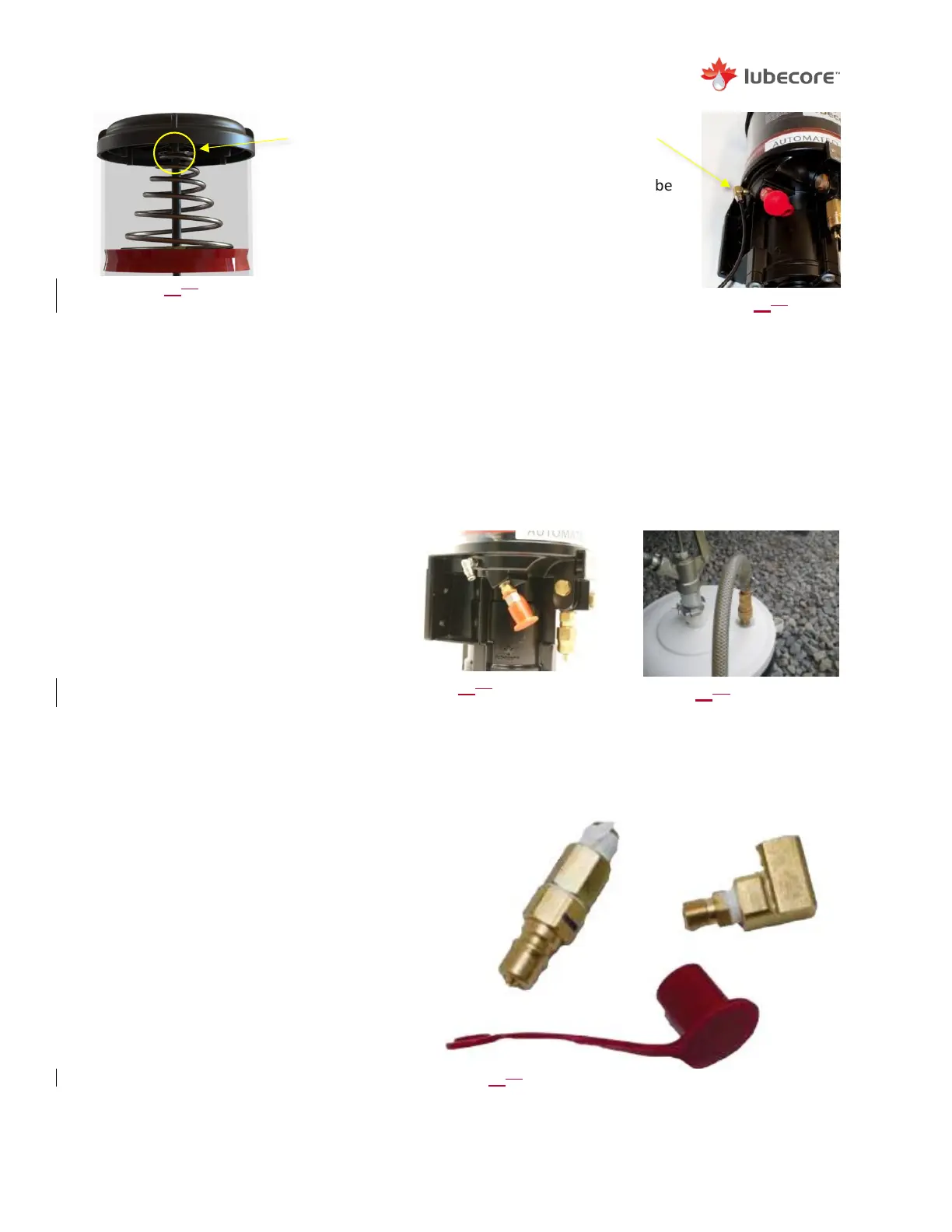

Heavy Duty Filter

The pump may optionally be equipped with

an inline heavy-duty grease filter. This filter,

directly mounted behind the male quick

disconnect prevents dirt and debris from

being pumped into the reservoir. Small

particles of dirt like sand, when introduced

into the lubrication system, may accumulate

in manifolds, injectors and distributors;

causing blockages or they may end up

causing damage to the equipment. It is

highly recommended that a Heavy Duty in-

line filter be installed on equipment working

in severe environmental conditions.

Figure 4650

Overflow

opening in

center of guide

rod

Figure 4549

Location of

overflow opening

Figure 4751

Dust Cap back on pump

Figure 4852

Pail hose quick

disconnect returned to

mating lid fitting

Figure 4953

Heavy Duty Filter Assembly (50.321)

Loading...

Loading...