IGA 320/23-LO Operating Manual Settings / parameter descriptions

20

4.5 Emissivity ε

For a correct measurement, it is necessary to adjust the emissivity. This emissivity is the

relationship between the emission of a real object and the emission of a blackbody radiation

source (this is an object, which absorbs all incoming rays and has an emissivity of 100%) at the

same temperature. Different materials have different emissivities ranging between 0% and

100% (settings at the pyrometer between: 10 and 100%). As such, the emissivity is also

dependent on the surface condition of the material, the spectral range of the pyrometer, and

the measuring temperature. The emissivity setting of the pyrometer has to be adjusted

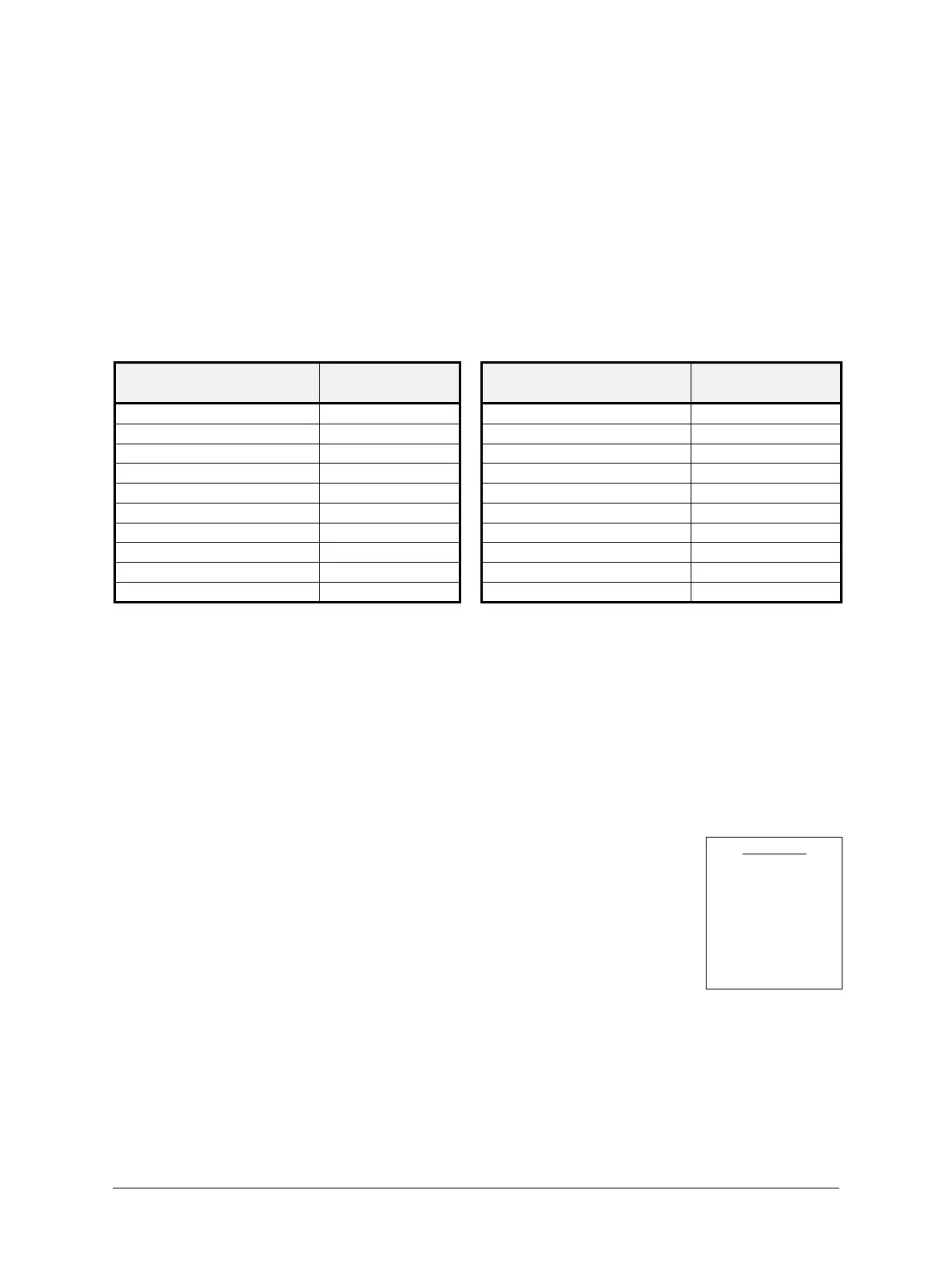

accordingly. Typical emissivity values of various common materials for the spectral range of the

instrument are listed below. The tolerance of the emissivity values for each material is mainly

dependent on the surface conditions. Rough surfaces have higher emissivities.

Measuring object

Emissivity [%]

(at 2.3 µm)

Measuring object

Emissivity [%]

(at 2.3 µm)

Brass oxidized (tarnished)

4.6 Transmittance

Measurements through windows slightly attenuates the measuring signal (due to the

transmittance). To obtain correct measuring results, the transmission of the window must be

compensated. Alternatively, the emissivity ε can be adapted.

4.7 EmiAutoFind

If the true temperature of the measured object is known, you can calculate the emissivity of the

measured object using the Emi: AutoFind function.

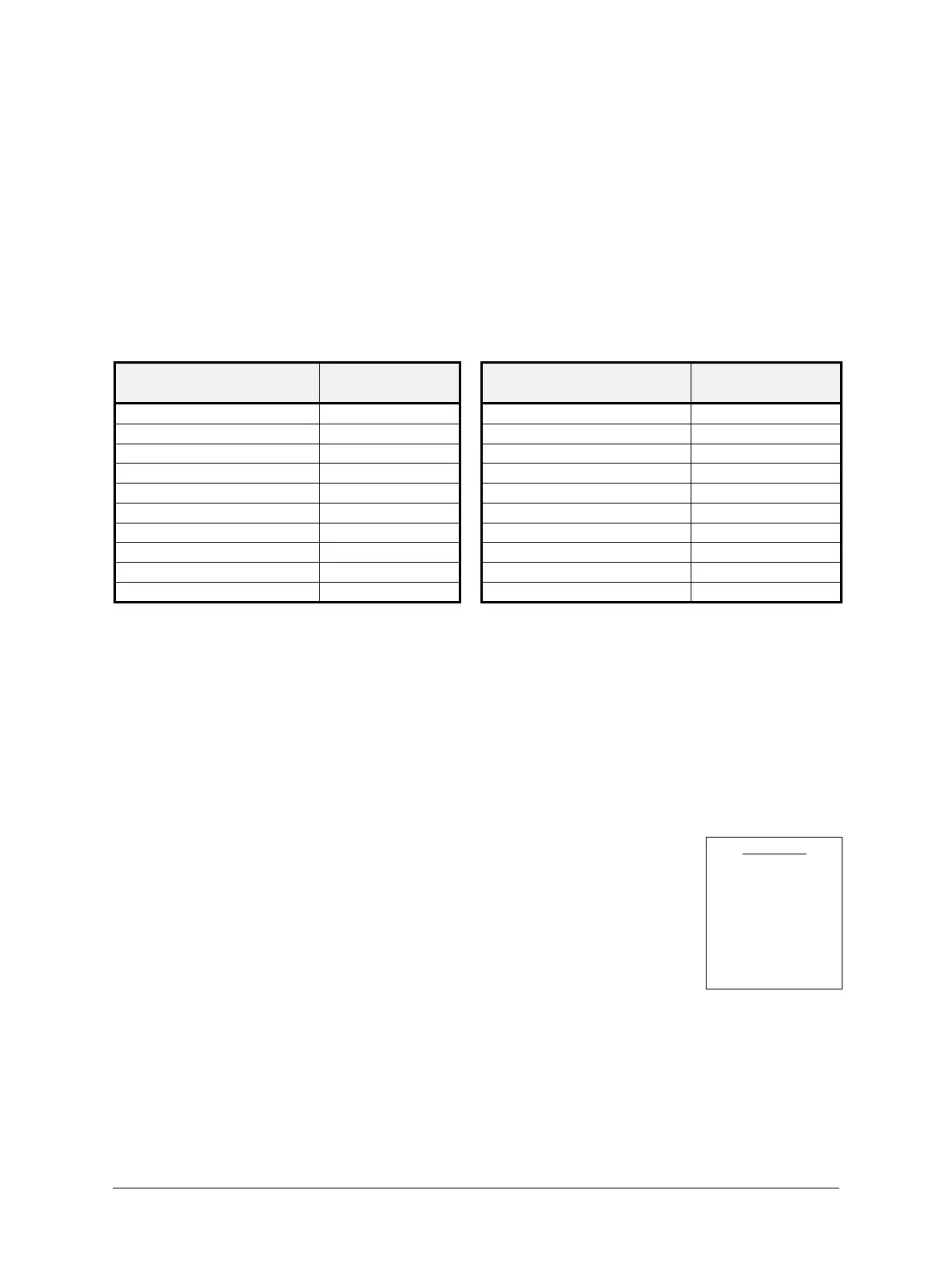

4.8 Response time / exposure time (t90)

The exposure time is the time the measured temperature has to be present

after an abrupt change so that the output value of the pyrometer reaches a

given measurement value. The time taken is to reach 90% of the recorded

temperature difference. In the “min” position, the device operates using its

time constant.

The dynamic exposure time adjustment prolongs the exposure time at the

lower range limit, also if t

90

is set to a lower value.

If the maximum value storage is selected and the measuring object has a low emissivity and the

measuring temperature is at the beginning of the range, a higher exposure time must be chosen

to prevent measurement errors. Longer exposure times can be used for the measurement of

objects, which have rapidly fluctuating temperatures to achieve constant temperature reading.

min

0.01 s

0.05 s

0.25 s

1 s

3 s

Loading...

Loading...