M&R Printing Equipment, Inc. - Glen Ellyn, Illinois

112

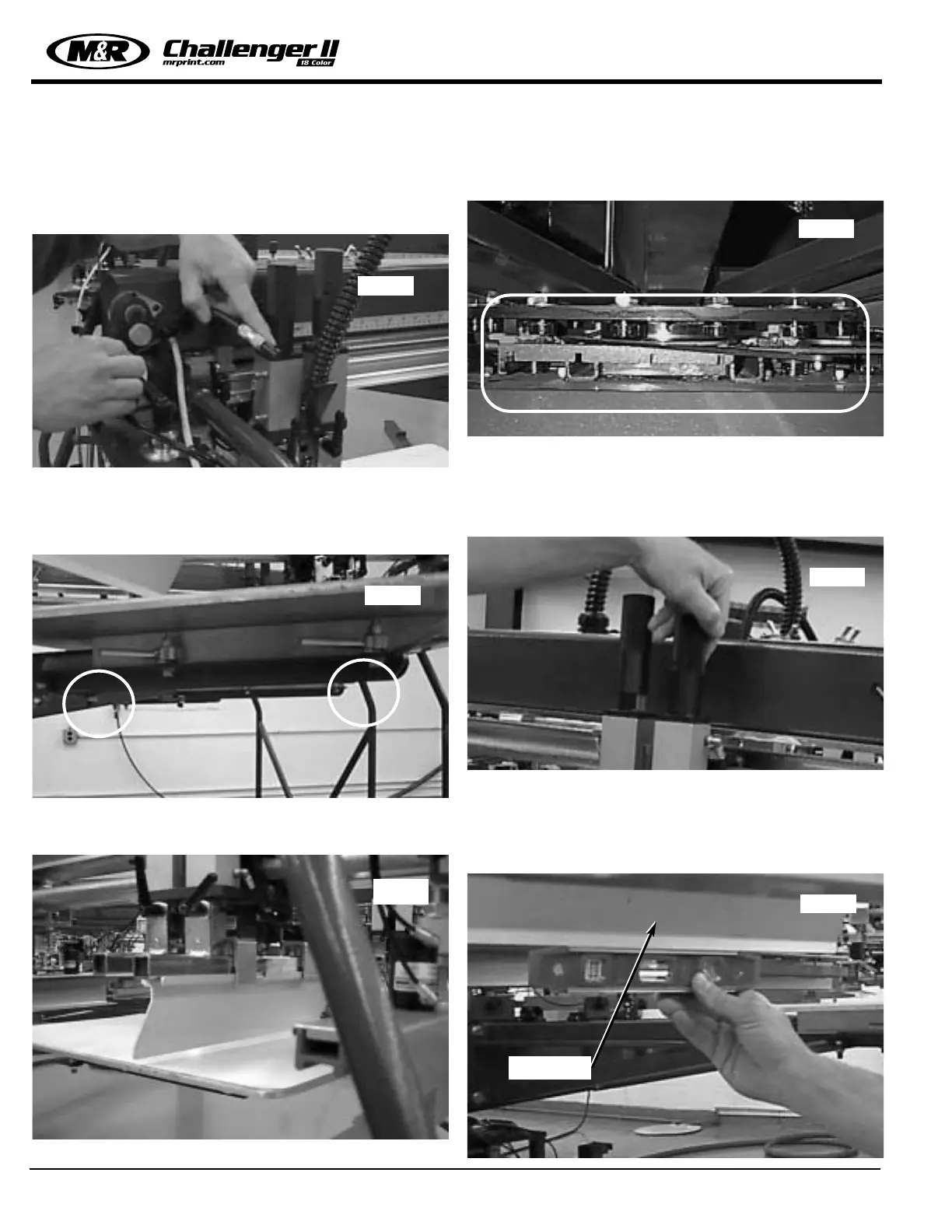

After doing this, unplug the air line located on the back of

the head (Tol-O-Matic Brass Cylinder Fitting). Use a brass

fitting union with plug , to plug the air line. This will allow you

to move the head carriage back and forth by hand without

resistance. (See Fig 6)

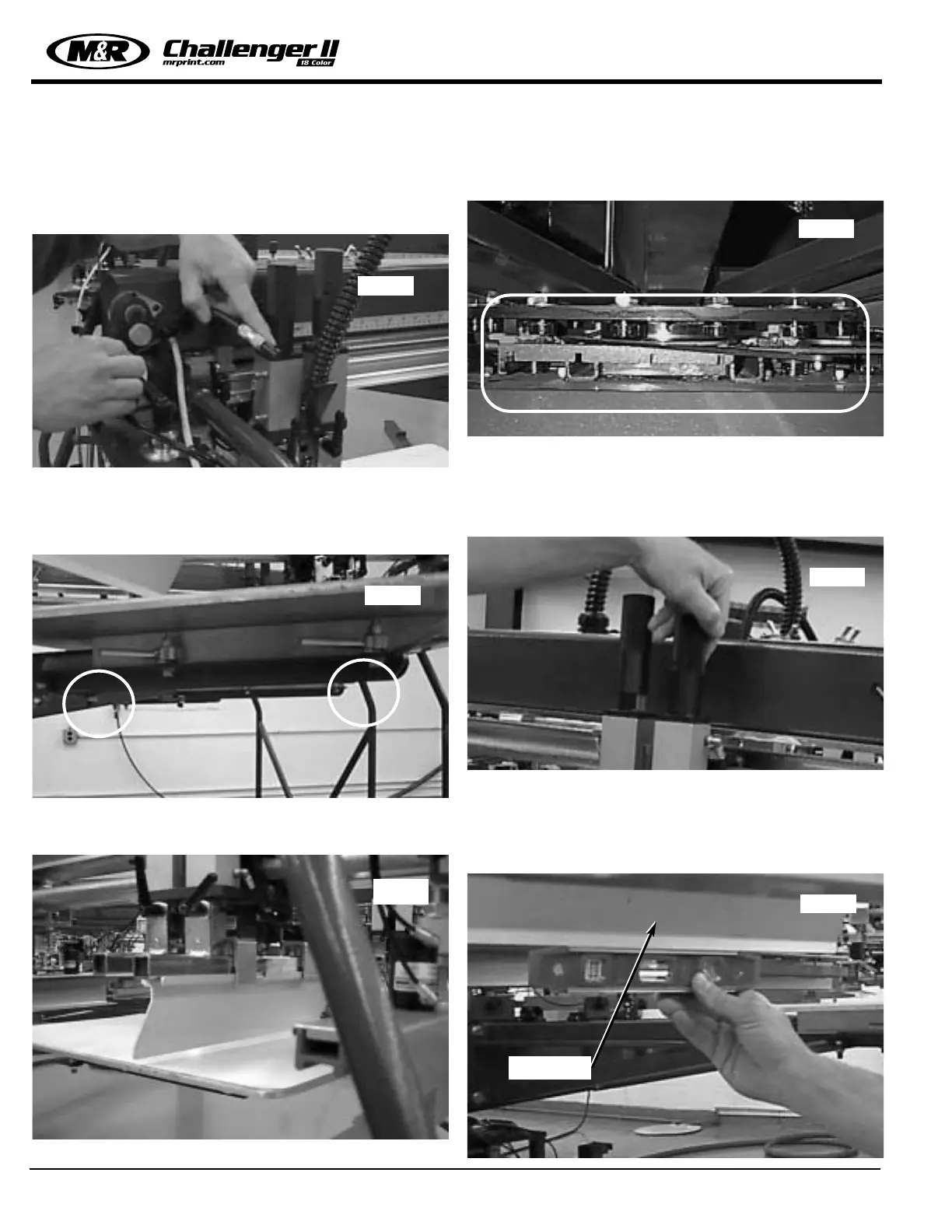

6. Before raising the table into the registration forks, make

sure that the nuts on the three adjustment points on the

base pallet frame are slightly thightened towards the mid-

dle of the adjustment range. (See Fig 7)

7. Now go ahead and raise the first pallet into the head used

for leveling the pallets. (See Fig. 8)

NOTE: If your machine has the “Central - Off Contact

Lever”, make sure it is set for the highest position, least

amount of off-contact. (See Fig. 9)

8. Now go ahead and move the head carriage towards the

center so that it is located above the center of the pallet.

Now adjust the flood pressure knobs counter-clockwise

until the edge of the flood bar comes in contact with the sur-

face of the Pallet. (See Fig. 10)

9. Bring pallet down by pressing the green reset button,

now use your small magnetic level (Torpedo Level) and

place it on the edge of the flood bar to make sure it is level.

If it is not level, make the necessary adjustments to make it

level. (See Fig 11)

Leveling the Pallets

Fig. 6

Fig. 7

Fig. 8

Fig. 9

Fig. 10

Fig. 11

Flood Bar

Loading...

Loading...