Operator Controls

M&R Printing Equipment, Inc. - Glen Ellyn, Illinois

36

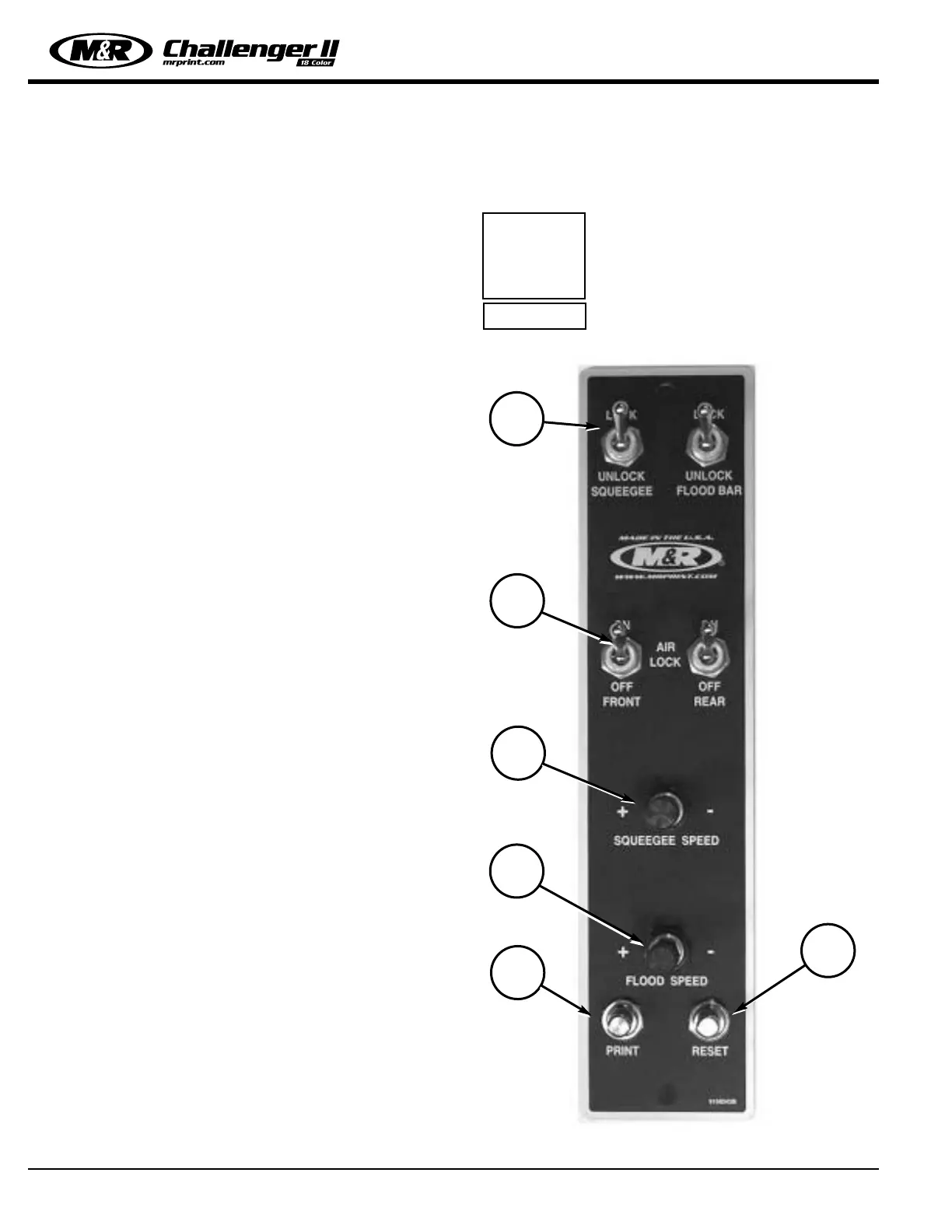

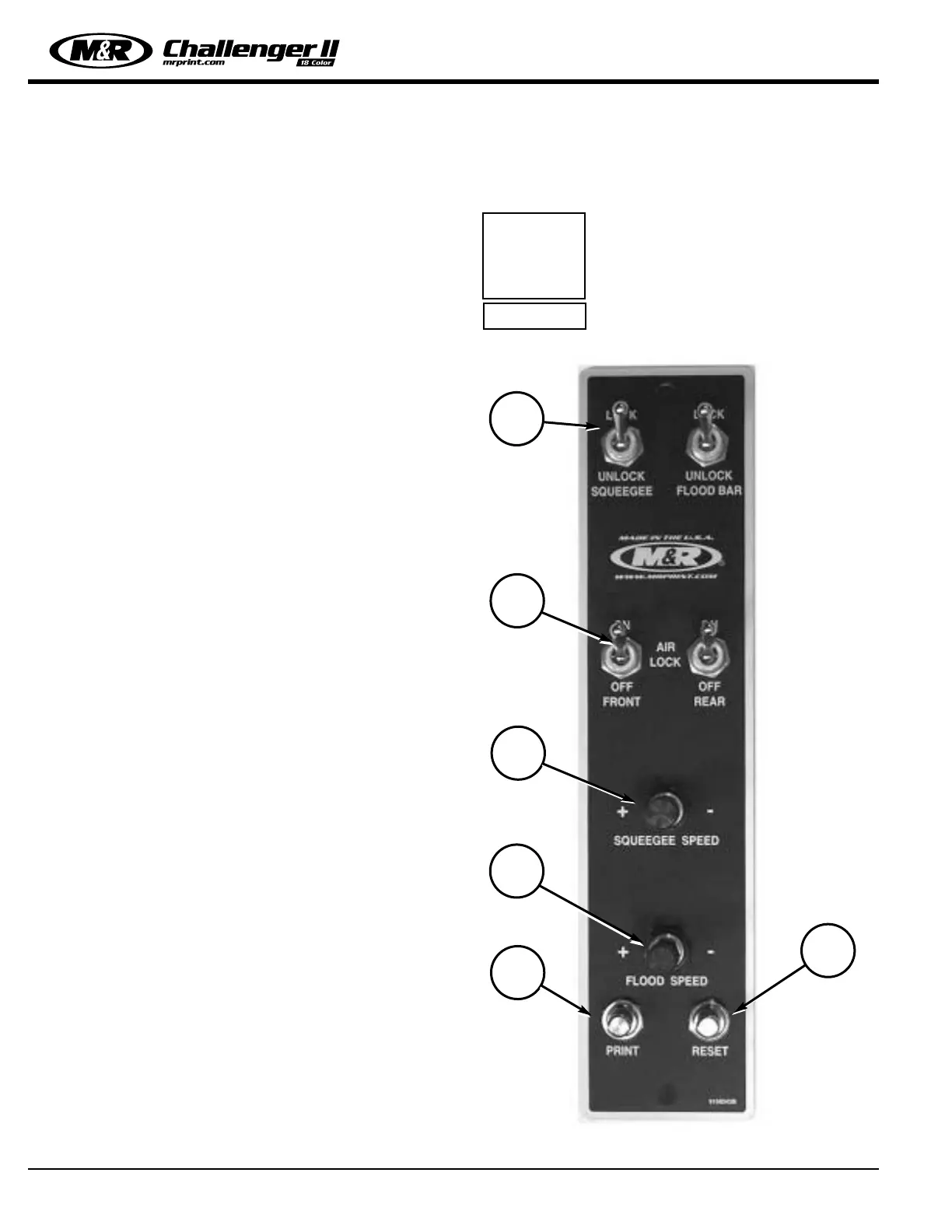

Individual Print Station Controls:

Each of the print stations used on the M&R Challenger

Series II includes individual controls for adjustment of flood

stroke speed, print stroke speed, independent print start,

On/Off switches for pneumatic screen frame clamps and, if

ordered as an option, squeegee/flood bar pneumatic

clamps, and “Reset” push button.

1. Squeegee/Flood Bar Pneumatic Locking Clamps

(Optional):

Located at the top of the print station control panel, these

toggle switches are used to lock the squeegee and flood

bar to their respective mounting bars. To lock the squeegee

or flood bar to the print station carriage mounting bars, sim-

ply position the squeegee or flood bar on the mounting bar

and place the toggle switch in the “On” lock position (up).

2. Pneumatic Screen Frame Locks:

Situated just below the pneumatic squeegee/flood bar lock-

ing clamps controls are the pneumatic screen frame locking

clamp control switches. The toggle switch on the left acti-

vates the front screen frame clamps, while the right toggle

switch activates the rear screen frame locking clamps. To

lock the screen frame into the screen frame holder assem-

bly, simply locate the screen frame in position and place the

toggle switches in the “On” (up) position. The pneumatic

cylinders (front & rear) will securely lock the screen frame

into the screen holder assembly. To release the screen

frame, simply move the toggle switches to the “Off” position

and remove the screen frame from the holder assembly.

3. Squeegee Speed Adjustment:

(Pneumatic Heads Only)

The squeegee speed may be independently adjusted by use

of this convenient control knob. To increase the squeegee

speed, turn the control knob counterclockwise. To decrease

the squeegee speed, turn the control knob clockwise.

4. Flood Bar Speed Adjustment:

(Pneumatic Heads Only)

The flood bar speed may be independently adjusted by use

of this convenient control knob. To increase the flood bar

speed, turn the control knob counterclockwise. To decrease

the flood bar speed, turn the control knob clockwise.

5. Independent Print Push Button:

As described in the Main Control Panel section, this push

button is used to cycle the individual print station manually.

The “Print” push button is also used during screen frame

set-up to check for proper screen placement during regis-

tration adjustments. To operate, place the “Single/Double”

toggle switch for the particular print station on the Main

Control Panel in the middle, or “Off” position. Now press

the “Print” push button on the print station control panel.

The index table will raise so that screen placement and reg-

istration may be checked.

To lower the index table, press the green “Reset” push but-

ton located just to the right of the “Print” push button on

the Print Station control panel.

NOTE: The “Single/Double” toggle

switch on the Main Control Panel must

be selected for either “Single” or

“Double” operation in order for the

print station to operate.

i

IMPORTANT!

1

2

3

5

4

6

Loading...

Loading...