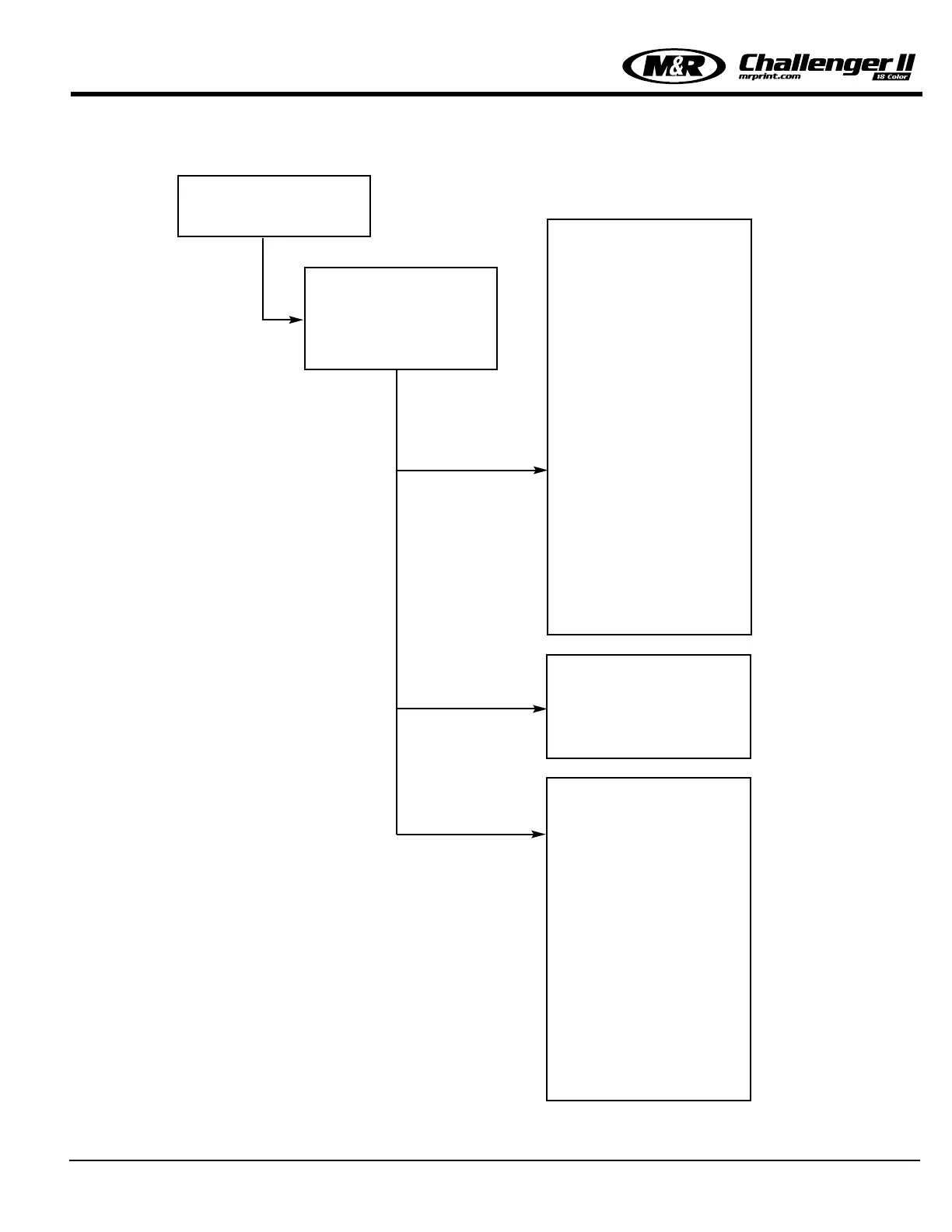

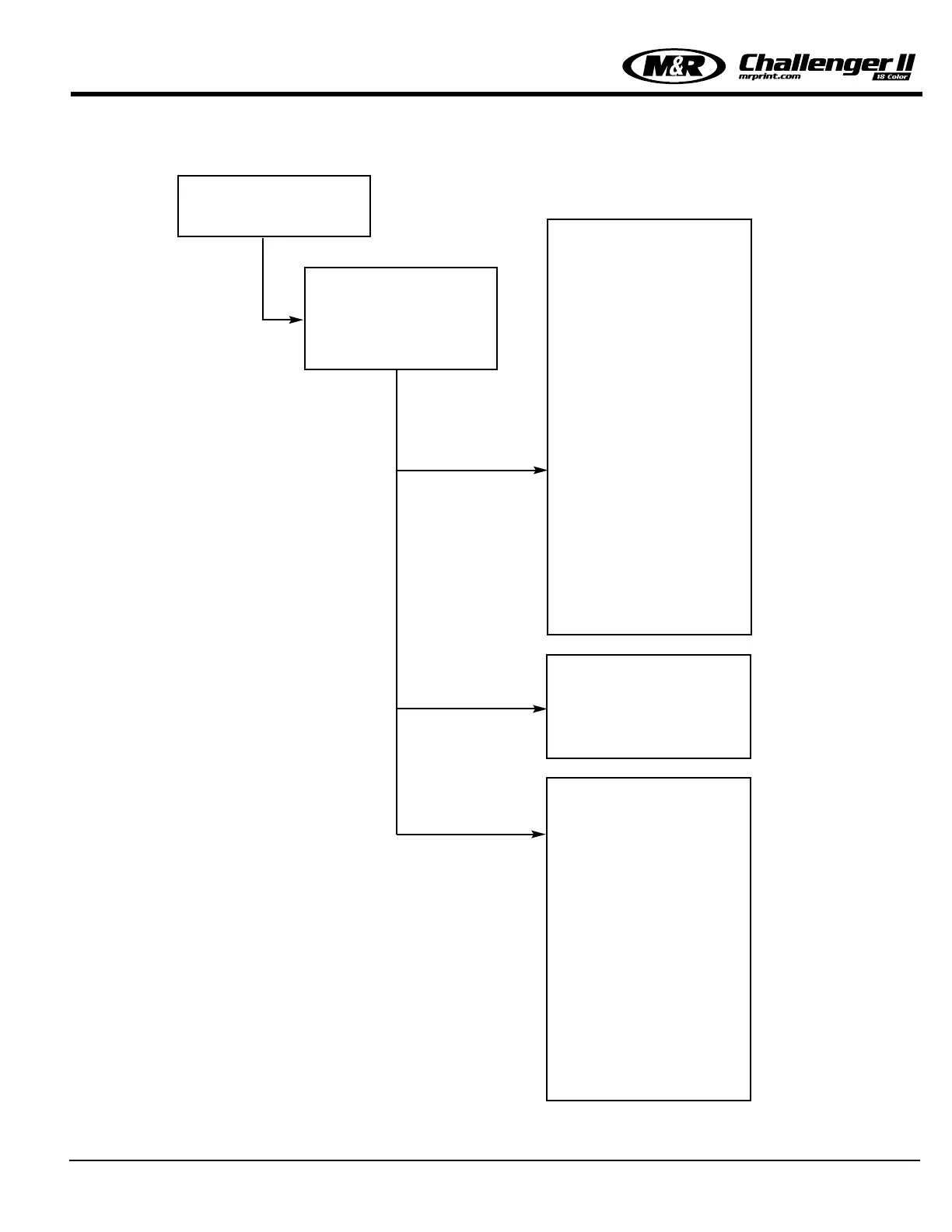

E 300 Operator Interface Logic Diagram

M&R Printing Equipment, Inc. - Glen Ellyn, Illinois

61

MAIN MENU SCREEN

PLC Identity No.

Program Version No.

MTA No.

SERVO DRIVE TEST

Regenerative load ratio: 0%

Effective load ratio: 0%

Peak load ratio: 0%

Motor Rotational Speed: 0.0 rpm

Actual Present: 0 pls

Feed Present: 0 pls

Deviation Counter: 0 pls

Motor Current: 0 R

Ready: OFF

Servo On: OFF

Zero Point Pass: OFF

At In-Positon: OFF

Zero Speed: OFF

Torque Limit: OFF

Servo Alarm: OFF

Servo Warning: OFF

Automatic Tuning: 0

Load Inertia Ratio: 0

Position Control Gain1 0

Speed Control Gain1: 0

Position Control Gain2: 0

Speed Control Gain2: 0

Speed Incremental Comp: 0

Servo Amp S/W Number:

Parameter Error 0-15: 0000

Parameter Error 16-31: 0000

Parameter Error 32-47: 0000

Servo Status: 0000

HARDWARE TEST

>Panel Test

>Proximities Test

>Motion Card Test

>Servo Drive Test

>Servo/Motion Card History

>Other Tests

SERVO MOTION CARD HISTORY

1:0000-NONE

2:0000-NONE

3:0000-NONE

4:0000-NONE

5:0000-NONE

6:0000-NONE

OTHER TESTS

Heads Print Pushbuttons 1 OFF

Heads Print Pushbuttons 2 OFF

Heads Print Pushbuttons 3 OFF

Heads Print Pushbuttons 4 OFF

Heads Print Pushbuttons 5 OFF

Heads Print Pushbuttons 6 OFF

Heads Print Pushbuttons 7 OFF

Heads Print Pushbuttons 8 OFF

Heads Print Pushbuttons 9 OFF

Heads Print Pushbuttons 10 OFF

Heads Print Pushbuttons 11 OFF

Heads Print Pushbuttons 12 OFF

Heads Print Pushbuttons 13 OFF

Heads Print Pushbuttons 14 OFF

Heads Print Pushbuttons 15 OFF

Heads Print Pushbuttons 16 OFF

Heads Print Pushbuttons 17 OFF

Heads Print Pushbuttons 18 OFF

Yellow Cords: OFF

No T-Shirt Sensor: OFF

Foot Pedal: OFF

Air Pressure Switch: OFF

PLC ERROR: 0

Loading...

Loading...