Â

50H - WEEKLY MAINTENANCE OR EVERY 50 HOURS OF SERVICE

CHECK

MI . . D ST3B S2

Belt tension

IMPORTANT

If the compressor belt has to be changed, check the tension again after the first 20 hours of operation.

- Unscrew the thumbscrews 1 and remove the housing 2.

- Lift cover 3 to gain access to the belts.

- Check the belts for signs of wear and cracking and change if necessary ( FILTER

CARTRIDGES AND BELTS).

COMPRESSOR BELT (air-conditioning option)

- Check the tension between pulleys, under normal pressure applied by the thumb

C (98 N/10kg), belt movement should be between 7 and 10 mm.

- Adjust if necessary.

- Loosen screws 8 by two to three turns.

- Tighten or loosen screw 9 to obtain the required belt tension.

- Retighten screws 8 (tightening torque 22 N.m).

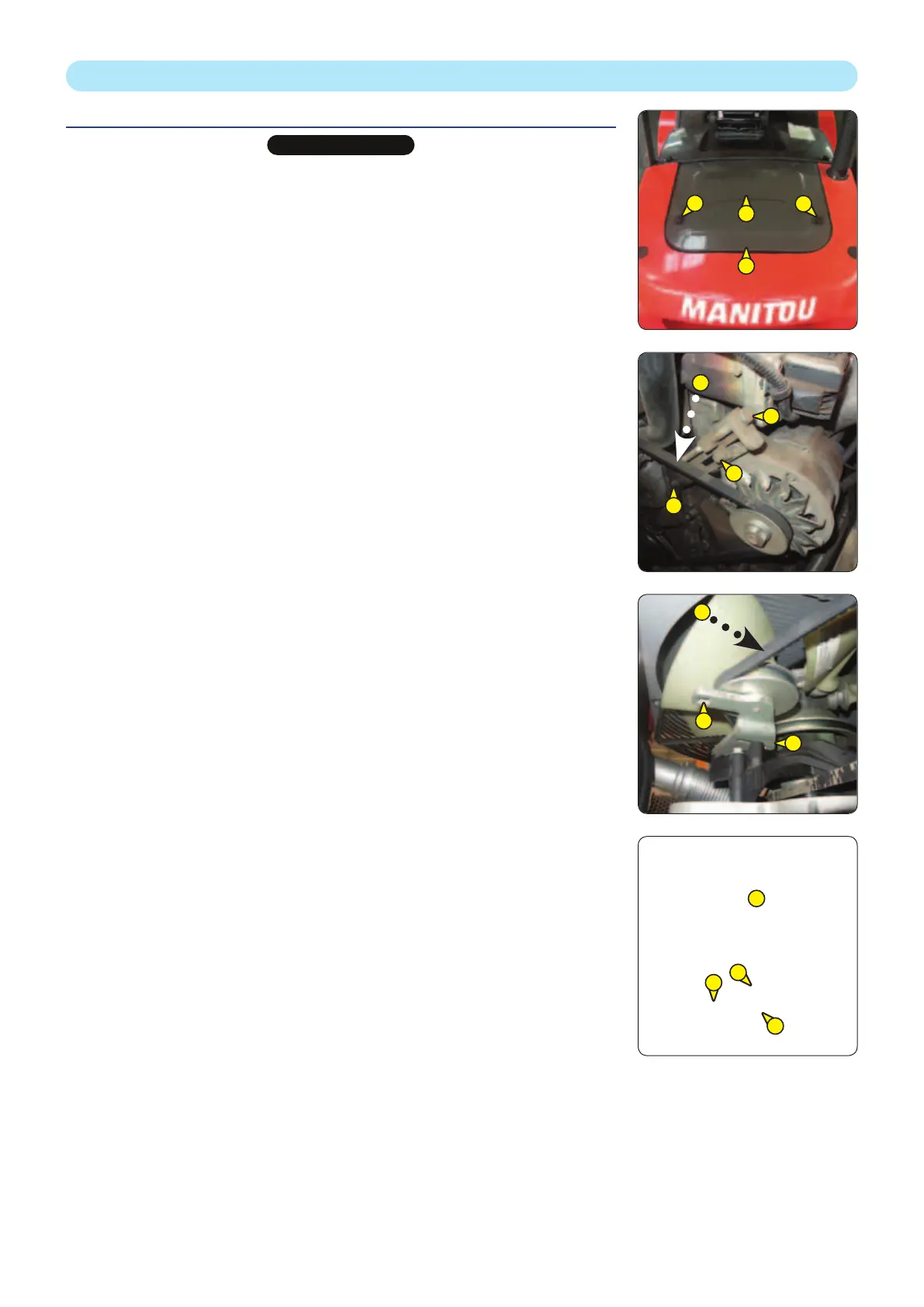

ALTERNATOR BELT

- Check the tension between pulleys, under normal pressure applied by the thumb

A (98 N/10kg), belt movement should be between 7 and 10 mm.

- Adjust if necessary.

- Loosen screws 4 by two to three turns.

- Tighten or loosen screw 5 to obtain the required belt tension.

- Retighten screws 4 (tightening torque 22 N.m).

FAN BELT

- Check the tension between pulleys, under normal pressure applied by the thumb

B (

98 N/10kg), belt movement should be between 7 and 10 mm.

- Adjust if necessary.

- Loosen screw 6 by two to three turns.

- Use a wrench to swivel the tensioner pulley 7 and obtain the required belt tension.

- Retighten screw 6 (tightening torque 22 N.m).

3 - 18

8

8

9

C

4

4

5

A

1

1

2

3

6

B

7

647650 (19/02/2018)

I-X 50L/60/70 D C ST3A S2 / MI 50L/60/70 D ST3B S2 / MI 50L/60/70 G S2

Loading...

Loading...