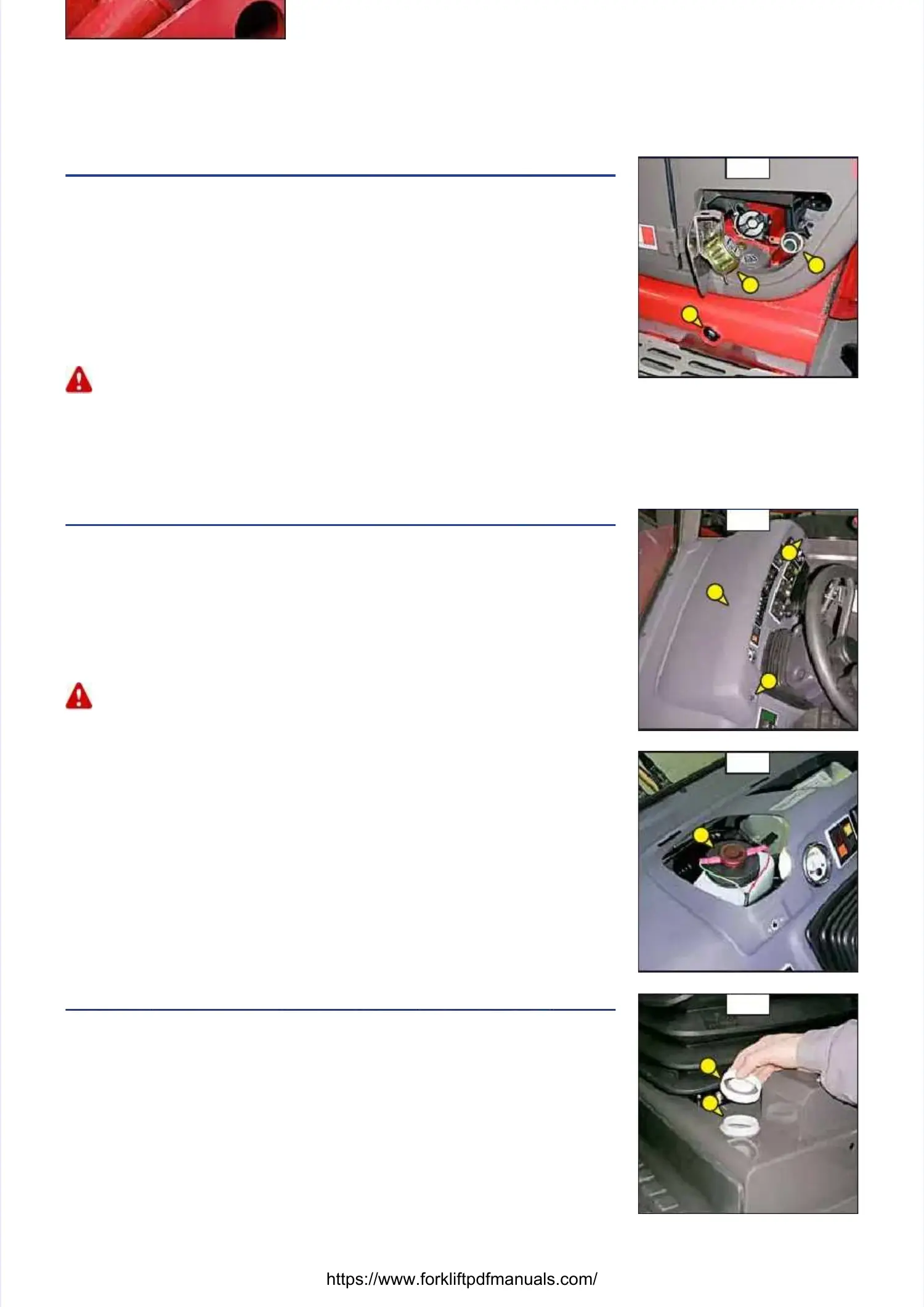

B6 - HYDRAULIC OIL LEVEL

B6 - HYDRAULIC OIL LEVEL

CHECKCHECK

Place the lift truck on level ground with the I.C. engine stopped, and the jib retracted andPlace the lift truck on level ground with the I.C. engine stopped, and the jib retracted and

lowered as far as possible.lowered as far as possible.

- Refer to gauge 1 (fig. B6).- Refer to gauge 1 (fig. B6).

- The oil level is correct when it is at the level of the red point.- The oil level is correct when it is at the level of the red point.

- If necessar- If necessary, add oil (see: 3 - MAINTENANCE: LUBRICANTS AND FUEL).y, add oil (see: 3 - MAINTENANCE: LUBRICANTS AND FUEL).

- Open the access panel for hydraulic oil filling.- Open the access panel for hydraulic oil filling.

- Remove cap 2 (fig. B6).- Remove cap 2 (fig. B6).

- Add oil through filler port 3 (fig. B6).- Add oil through filler port 3 (fig. B6).

Use a clean funnel and clean the Use a clean funnel and clean the underside of the oil drum before filling.underside of the oil drum before filling.

- Put the cap back and close the access panel for hydraulic oil filling.- Put the cap back and close the access panel for hydraulic oil filling.

- Check visually that there is no leakage in the tank and pipes.- Check visually that there is no leakage in the tank and pipes.

Always maintain the oil level at maximum as cooling depends on the oil flowing through the tank.Always maintain the oil level at maximum as cooling depends on the oil flowing through the tank.

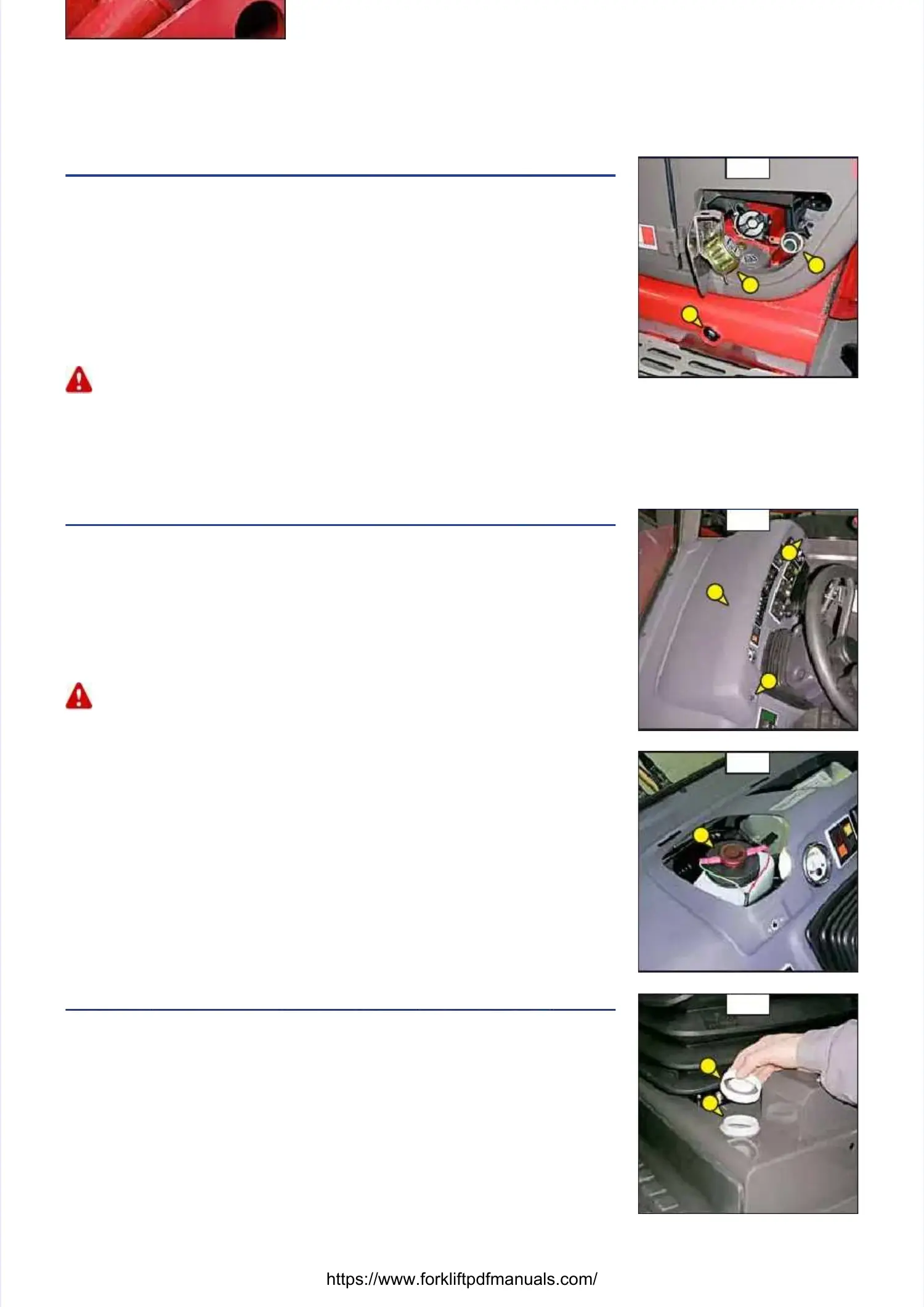

B7 - BRAKE OIL LEVELB7 - BRAKE OIL LEVEL

CHECKCHECK

Place the lift truck on level ground.Place the lift truck on level ground.

-- Loosen screw 1 (fig. B7/Loosen screw 1 (fig. B7/1) and remove the braking oil tank acces1) and remove the braking oil tank access panel 2 (fig. B7/1)s panel 2 (fig. B7/1)..

- The level is correct when it is at the MAXI level on the tank.- The level is correct when it is at the MAXI level on the tank.

-- If necessary, add oil (see: 3 - MIf necessary, add oil (see: 3 - MAINTENANCE: LUBRICANTS AND FUEL) by tAINTENANCE: LUBRICANTS AND FUEL) by the filler port 3he filler port 3

(fig. B7/2).(fig. B7/2).

- Check visually that there is no leakage in the tank and pipes.- Check visually that there is no leakage in the tank and pipes.

If the braking oil If the braking oil level is level is abnormally low, consult your dealerabnormally low, consult your dealer..

B8 - WINDSCREEN WASHER LIQUID LEVELB8 - WINDSCREEN WASHER LIQUID LEVEL

CHECKCHECK

- Remove the filler cap 1 - Remove the filler cap 1 (fig. B8).(fig. B8).

- Check visually the level.- Check visually the level.

-- If necessary add windscreen washer liquid (see: If necessary add windscreen washer liquid (see: 3 - MAINTENANCE: LUBRIC3 - MAINTENANCE: LUBRICANTS ANDANTS AND

FUEL) by filler port 2 (fig. B8).FUEL) by filler port 2 (fig. B8).

B7/1B7/1

11

11

22

B7/2B7/2

33

B8B8

11

22

B6B6

11

22

33

Loading...

Loading...