3 - 38

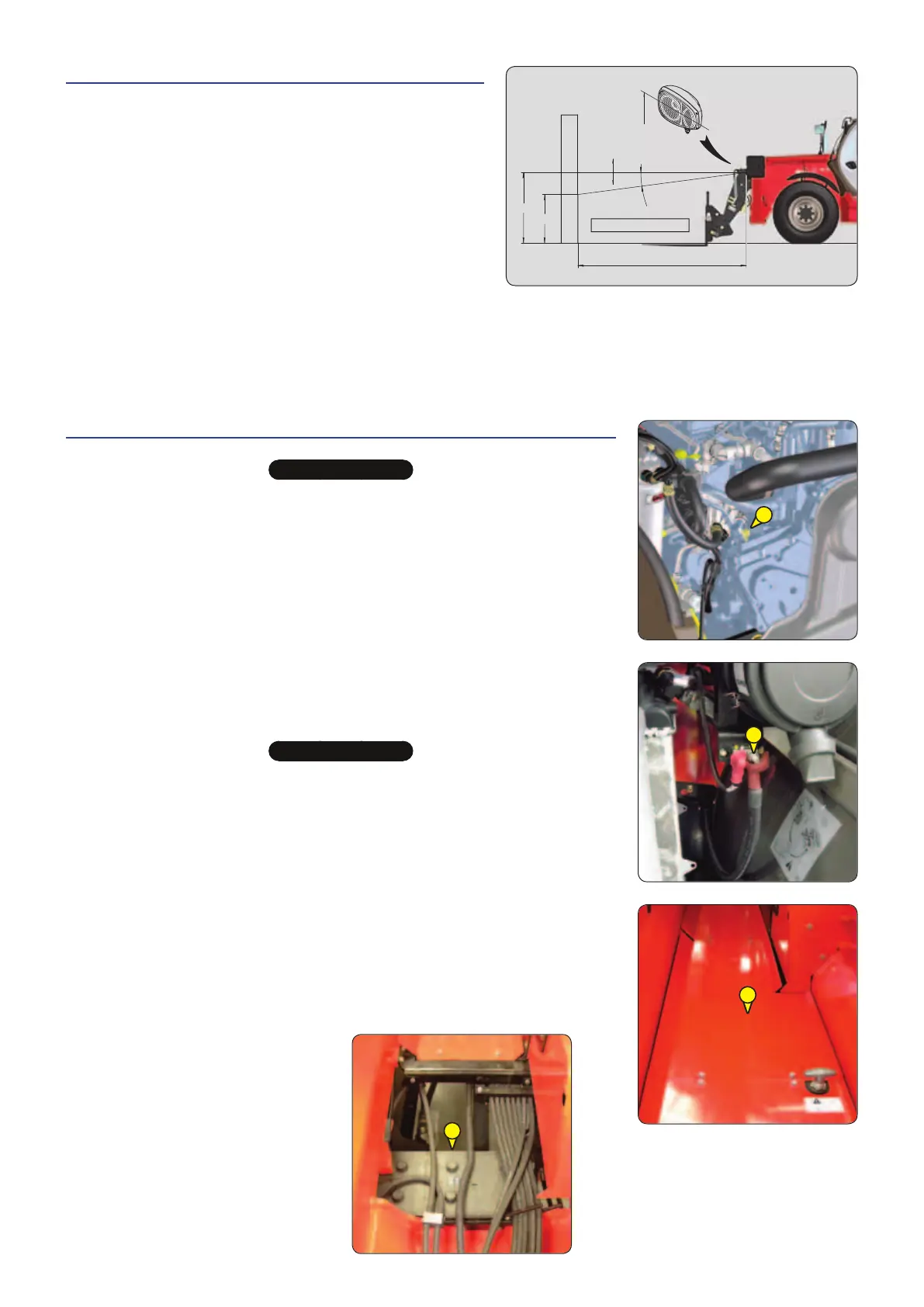

G3 – FRONT HEADLIGHTS

ADJUSTING

RECOMMENDED SETTING

(as per standard ECE-76/756 76/761 ECE20)

Set to - 2% of the dipped beam in relation to the horizontal axis

of the headlamp.

ADJUSTING PROCEDURE

- Place the unladen lift truck in the transport position and

perpendicular to a white wall on flat, level ground.

- Check the tyre pressures (see: 2 - DESCRIPTION: FRONT AND

REAR TYRES).

- Place the forward/reverse selector in neutral.

CALCULATING THE HEIGHT OF THE DIPPED BEAM (H2)

• h1 = Height of the dipped beam in relation to the ground.

• h2 = Height of the adjusted beam.

• l = Distance between the dipped beam and the white wall.

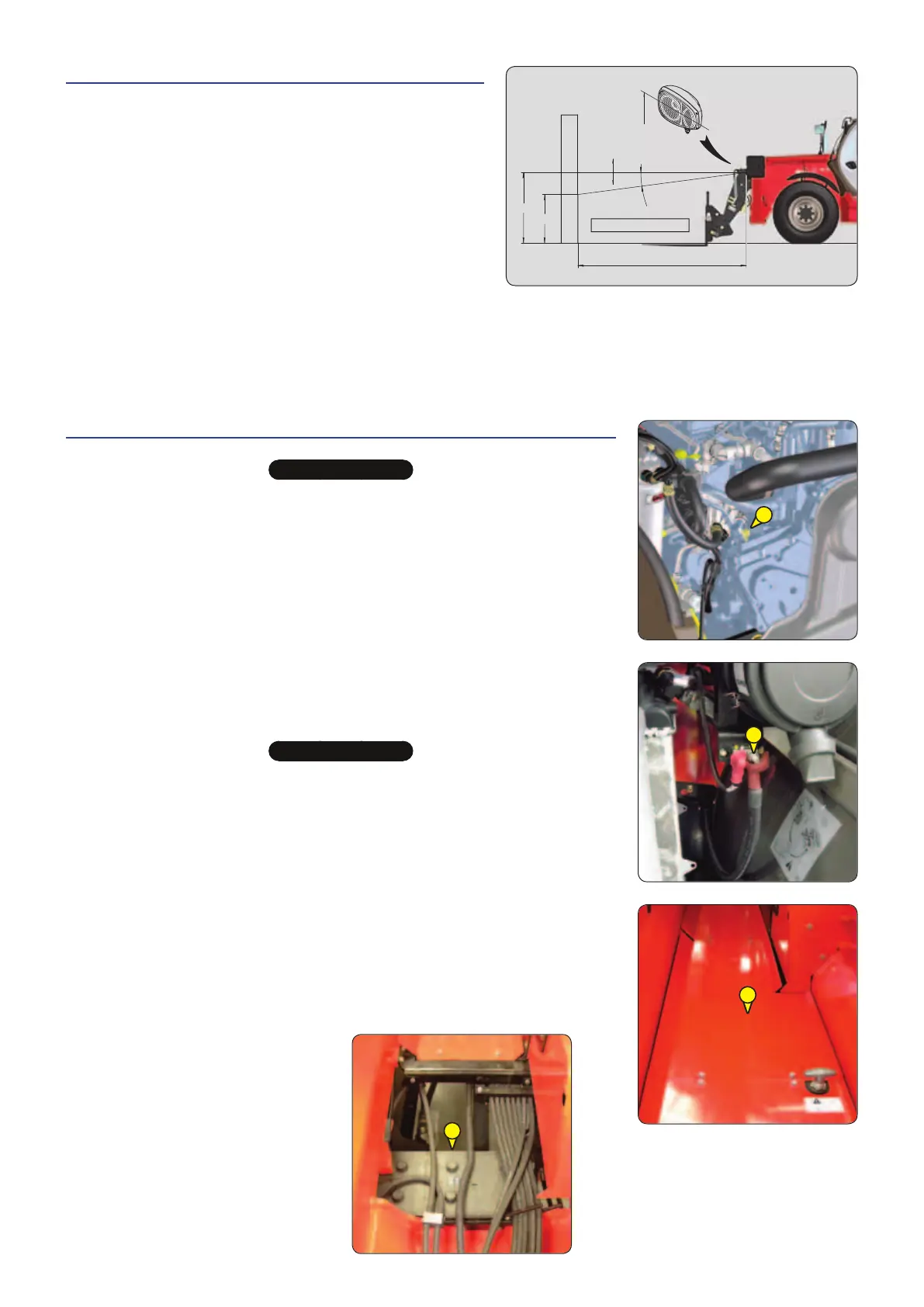

G4 – BATTERY FAILURE

CHANGE

IMPORTANT

Operate the battery cut-out no less than 30 seconds after having switched off the ignition with the ignition key.

Handling and servicing a battery can be dangerous, take the following precautions:

- Wear protective goggles.

- Keep the battery horizontal.

- Never smoke or work near a naked flame.

- Work in a well-ventilated area.

- In the event of electrolyte being spilled onto the skin or splashed in the eyes, rinse thoroughly with cold water for

15 minutes and call a doctor.

- Open the engine bonnet.

- Bring a floating battery of the same type as the one used for the lift truck and

battery cables.

- Connect the floating battery while respecting the polarity (-) (+).

- Start the lift truck and remove the cables as soon as the engine is running.

IMPORTANT

Raise the boom and place the boom safety wedge on the rod of the lifting cylinder (see: 1 - OPERATING AND SAFETY

INSTRUCTIONS: LIFT TRUCK MAINTENANCE INSTRUCTIONS).

- Remove the protective casing 1.

- Change the battery 2.

+%

-%

l

h1

h2

-2%

h2 = h1 - (l x 2 / 100)

h1

1

+

2

–

647563 (22/08/2017)

MT 1435/1440/1840 EASY 75D ST3B S1

Loading...

Loading...