UNDERCARRIAGE GRT880 SERVICE MANUAL

8-10

Published 10/19/2017, Control # 618-00

REAR AXLE OSCILLATION LOCKOUT

SYSTEM

Description

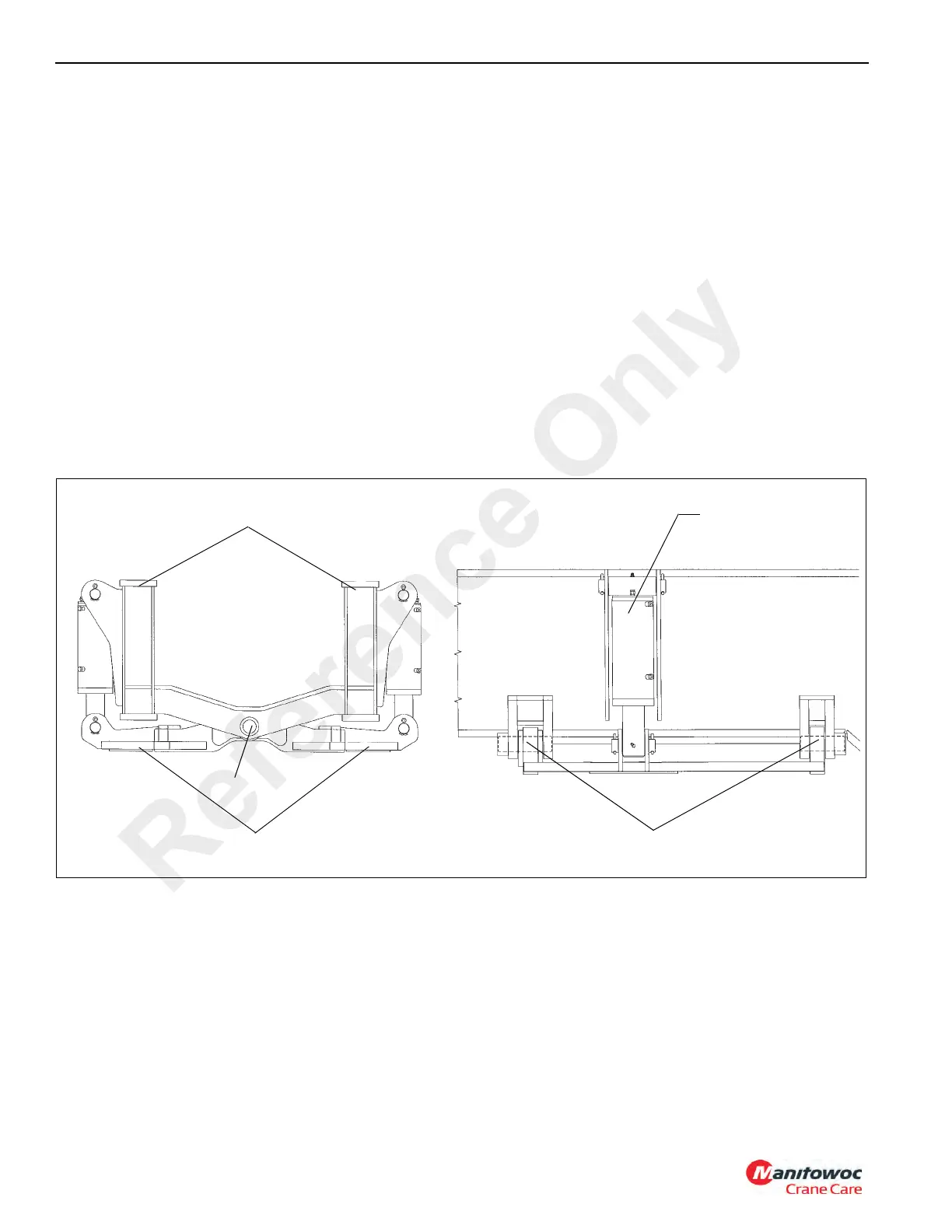

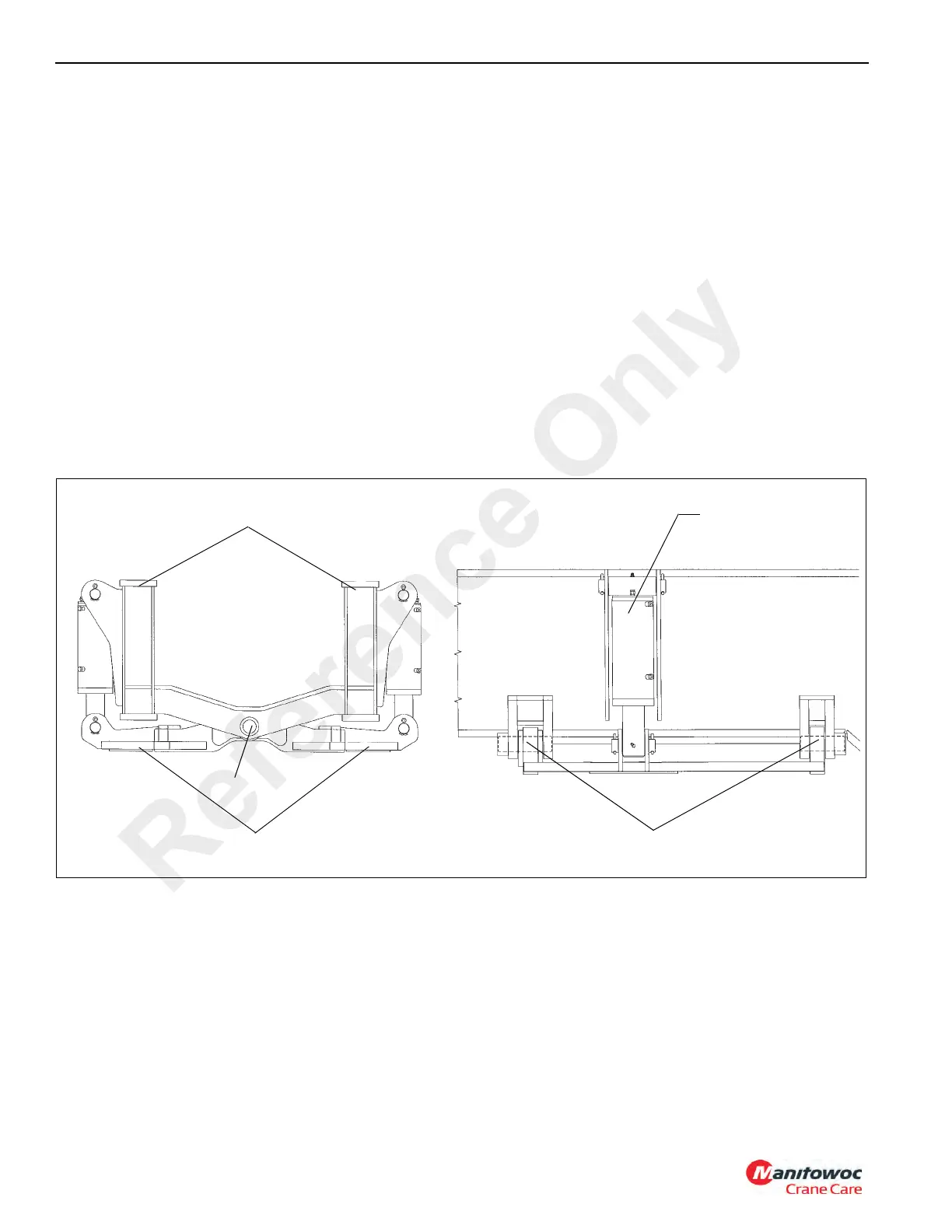

The rear axle oscillation system Figure 8-11 and Figure 8-12

consists of two lockout cylinders, a lockout valve, and an

angle encoder. The lockout cylinders are mounted between

a cradle (fifth wheel) and the carrier frame. The lockout valve

is mounted on the left inner center frame rail and

hydraulically controls the oscillating abilities of the lockout

cylinders. The angle encoder is located in the electrical

swivel assembly.

Theory Of Operation

The rear axle is mounted on a cradle (fifth wheel) allowing

maximum oscillation of 25.4 cm (10 in) total while traveling

over uneven terrain. Oscillation is provided only when the

superstructure is within 3° left or right of directly over the

front. When the superstructure is within 3° left or right of

directly over the front, the RCL sends a CAN bus message to

the Crane Control System to allow axle oscillation. When the

Crane Control System receives this message it switches ON

a digital output thus energizing the axle oscillation solenoids.

When the solenoids are energized, the valve spools are

shifted to allow hydraulic transfer between the two lockout

cylinders. As one side of the axle is forced up by traveling

over uneven terrain, the hydraulic oil flows from the rod end

of cylinder A to the barrel end of cylinder B and from the rod

end of cylinder B to the barrel end of cylinder A. The system

is not pressurized and oil is moved from one cylinder to the

other by the action of the axle moving the cylinder.

When the superstructure is more than 3° left or right of

directly over the front, the Crane Control System switches

OFF the digital output thus de-energizing the axle oscillation

solenoids. This de-energizes the solenoids on the lockout

valve and allows the springs in the valve to shift the valve

spools to the closed position to prevent hydraulic oil flow

between the cylinders. By stopping the flow of oil, a hydraulic

lock is created and the axle is held rigid in that position.

Pivot Point

Pivot Point

Oscillation Lockout

Cylinder

Carrier Frame

Fifth Wheel

B

A

FIGURE 8-11

Reference Only

Loading...

Loading...