Triplematic

Triplematic 201708 EN 35

Maintenance and Service

6.3 Change the grinding wheel and

fit the grinding wheel guard

WARNING Before a chain is sharpened, make

sure that the grinding wheel is not cracked, does

not vibrate or wobble. There is a simple test (called

the “ring test”) that you can do to check for damage

(see step 1 of section 6.2.1, “Prepare the grinding

wheel”).

IF THE GRINDING WHEEL IS DAMAGED IT

MUST BE REPLACED IMMEDIATELY. If abnormal

vibrations occur during operation, stop the machine

immediately and check the condition of the grinding

wheel.

The machine comes with 2 grinding wheels of

different sizes. To order more grinding wheels, see

9, “Accessories and Spare Parts”.

1. Press the emergency stop button to turn the

power off.

2. Lift the grinding head to its most upright

position.

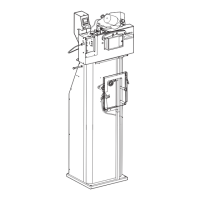

3. If the grinding wheel guard is already attached:

Loosen the 2 screws (D) and remove the guard

(C).

4. Hold the grinding wheel and loosen the nut

(B).

B

C

A

D

5. Remove the grinding wheel (A) from

the grinding wheel axis and discard it in

accordance with local, state and national laws

and regulations.

6. Place a new grinding wheel (A) on the grinding

wheel axis.

7. Tighten the nut (B) by hand to secure the

grinding wheel in its position. Do not over-

tighten the nut.

8. Place the grinding wheel guard (C) in its

position and fasten the 2 screws (D).

9. Center the grinding wheel following the

instructions on step 14 of section6.2.5, “Make

the grinding settings”.

6.4 Set the depth gauge height

1. Do a sharpening test on a test chain, according

to the instructions in section 8.2, “Sharpening

test”.

2. Verify the correct depth gauge setting (refer to

the illustration).

• Use a depth gauge tool to assess whether

you need to adjust the setting.

• If the depth gauge requires adjustment, use a

flat file to set it. Once you have set the depth

gauge, refer back to the template to make

sure it meets the correct specifications.

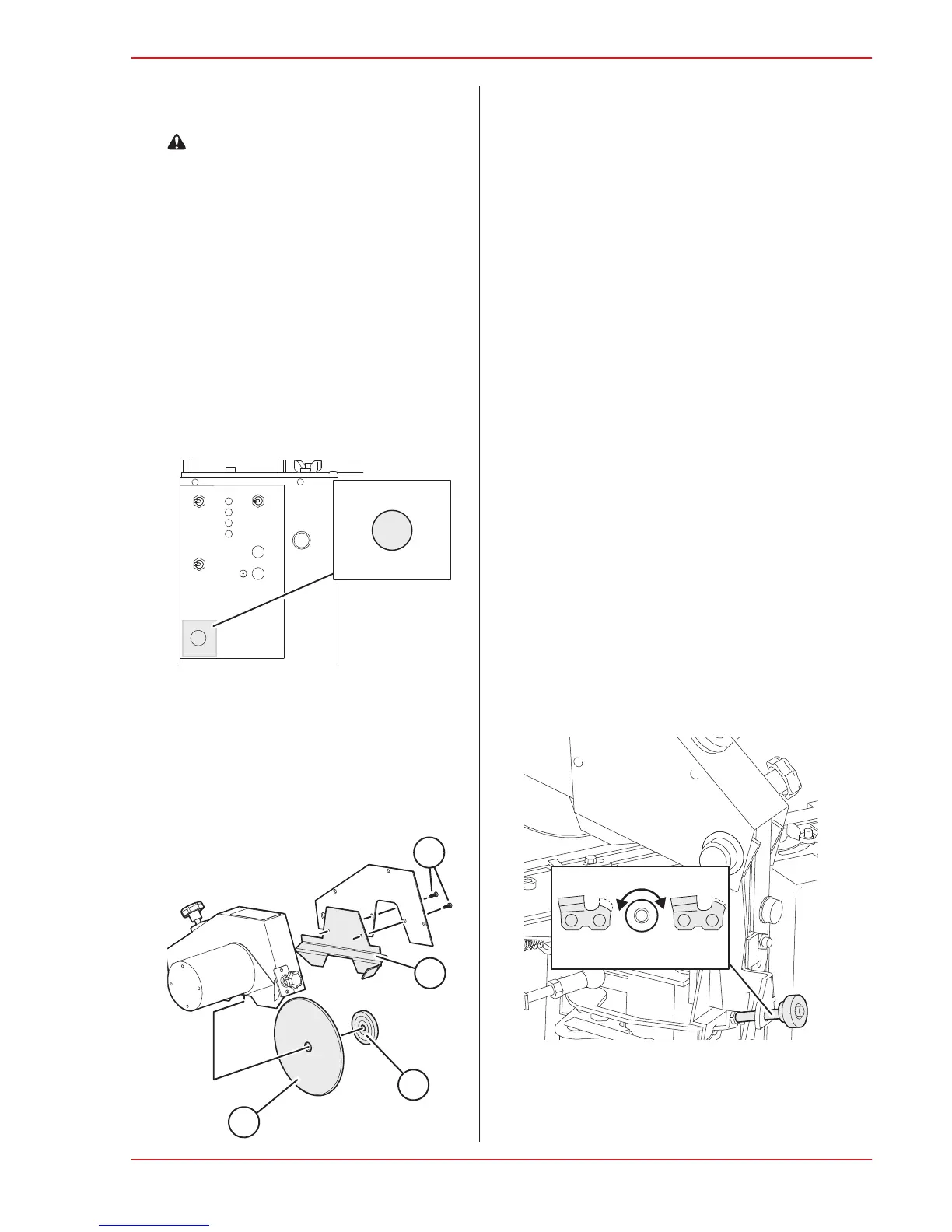

3. Use the set depth gauge to adjust the position

of the machine to set up the remaining depth

gauges. Turn the depth gauge height knob:

Loading...

Loading...