INSTALLATION PROCEDURES

3-9

3.7 STEAM CONNECTION

For machines equipped with optional steam heat, install piping in accordance with approved

commercial steam practices. Steam requirements are shown in the table below. Failure to install the

supplied steam filter may void the warranty.

Never touch internal or external steam pipes, connections, or components.

These surfaces can be extremely hot and will cause severe burns. The steam

must be

turned off and the pipe, connections, and components allowed to

cool before the pipe can be touched

Model Unit 20 lbs. 30 lbs. 40 lbs. 60 lbs. 80 lbs.

Steam Inlet Size NPT ½” ½” ½” ½” ¾”

Steam Consumption kg/hr lb/hr

11 (24.15) 11 (24.15) 23.5 (51.75) 34.4 (75.9) 56.3(124.2)

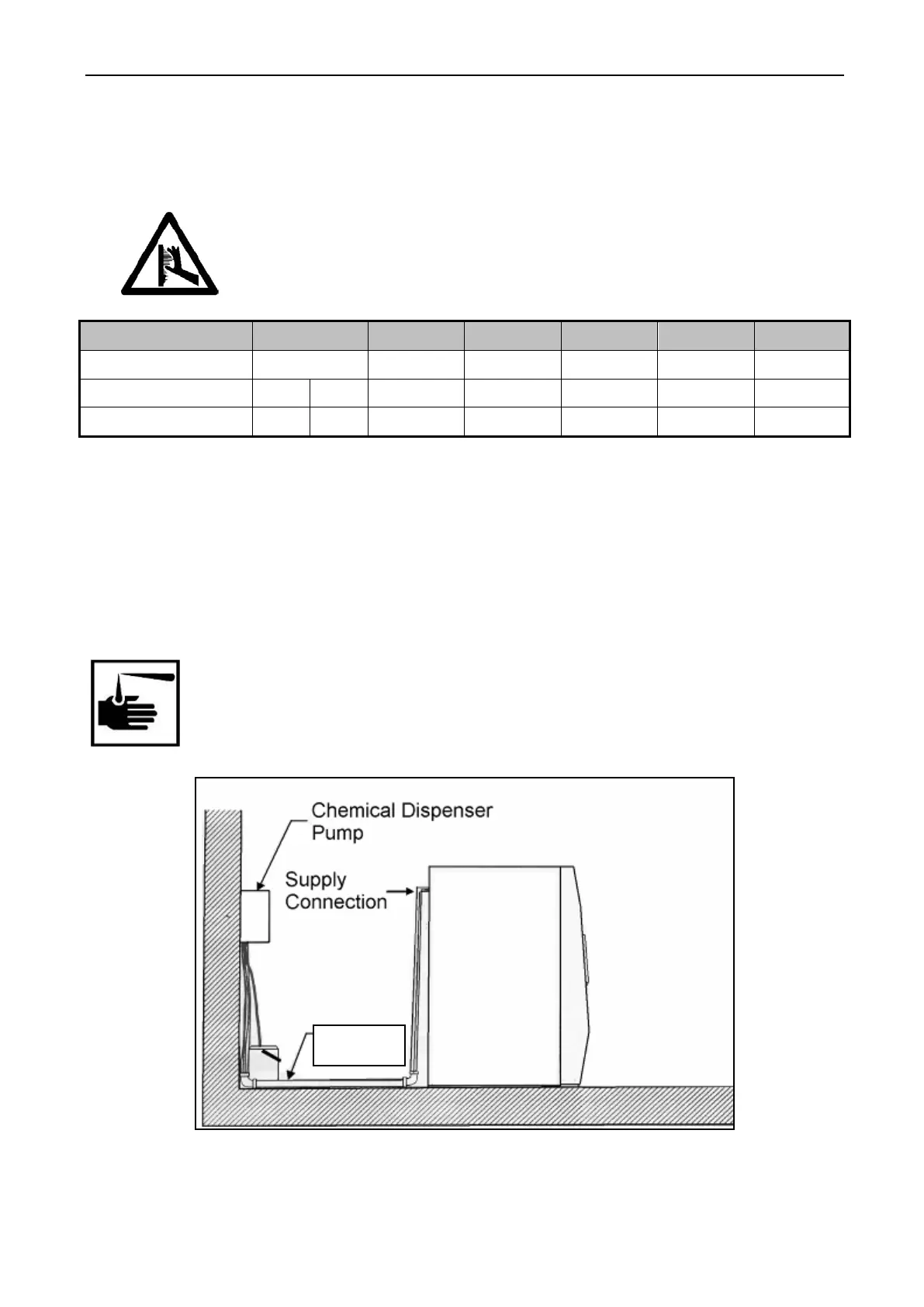

3.8 EXTERNAL CHEMICAL SUPPLIES

The following procedures must be observed when connecting any chemical injector to the

washer – extractor. See figure 3-8.

Undiluted chemicals dripping can damage the machine. Therefore, all chemical supply

dispenser pumps should be mounted below the washers injection point. All dispensers tubing

should also run below the injection point. Loops do not prevent drips if these instructions are not

followed. Failure to follow these instructions could damage the machine and void the warranty.

Wear Eye and hand protection when handling chemicals. Always avoid direct

contact with raw chemicals. Read the manufacturer’s directions for accidental

contact before handling chemicals. Ensure that an eye –

emergency shower are within easy reach. Check at regular intervals for chemical

Fig. 3-8 External chemical supply connection detail

Loading...

Loading...