INSTALLATION PROCEDURES

3-8

For personal safety and for proper operation, the machine must be grounded in accordance

with state and local codes and in the USA in accordance with the National Electric Code, article

250 – 96.

The ground connection must be to a proven earth ground, not to conduit or water pipes.

Do not connect the system is used, the neutral (N) leg at the terminal strip.

If a DELTA supply system is used, the high leg may be connected to L1, L2 or L3, as the

machines are equipped with control transformer.

Insure that the control transformer taps are connected in accordance with the incoming line

voltage. Verify connections as shown on the schematic with each machine.

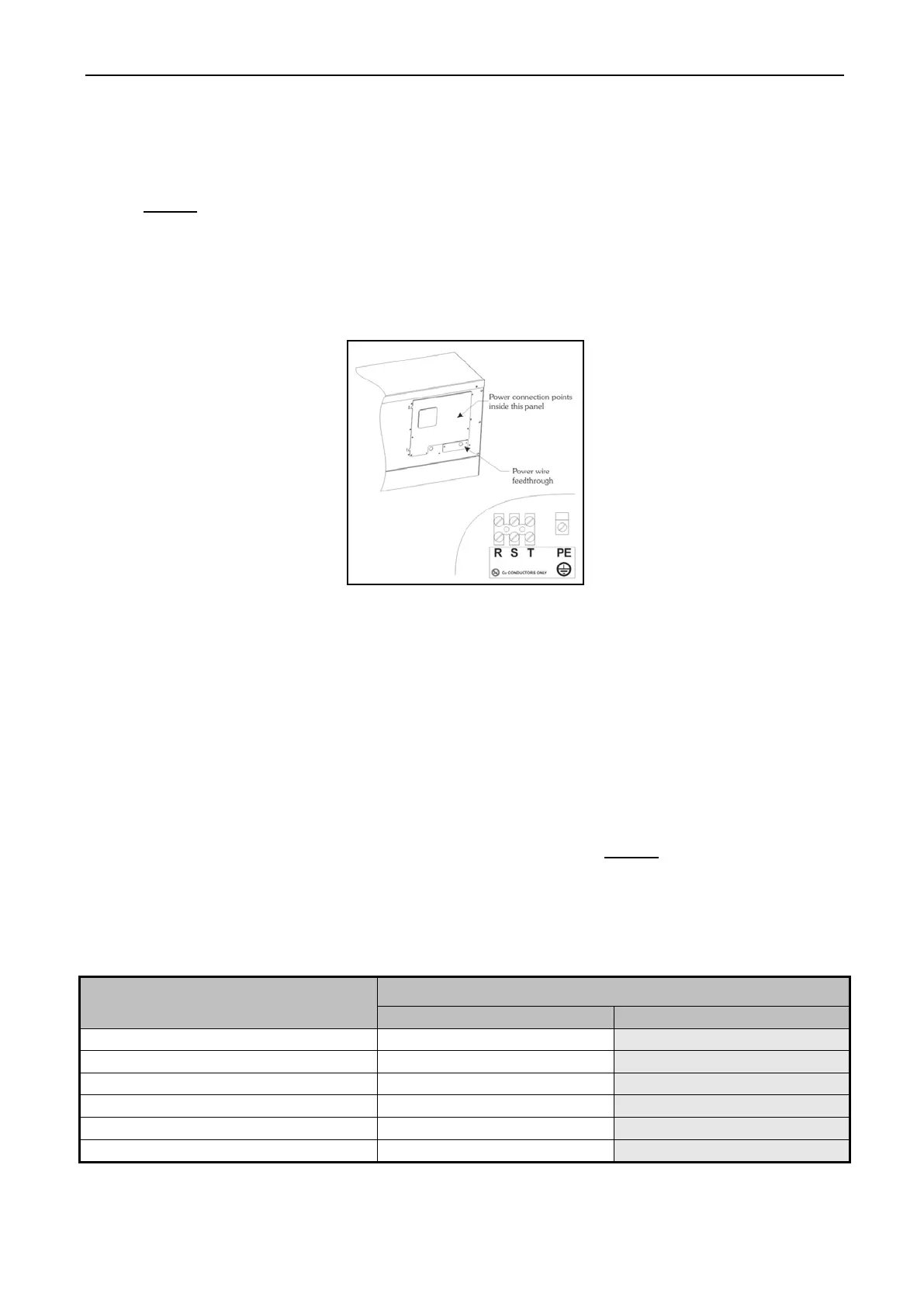

Fig. 3-7 Electrical Service Connection Detail

3.6 WATER CONNECTION

Individual hot and cold plumbing lines with individual shut – off valves must be available to

the machine. Hot water should be minimum of 160 °F (70 °C). If lower temperature water is used

the machine should be equipped for steam heating to heat the wash solution to desired temperature.

Best performance will be realized if water is provided at a pressure of 30 – 87 psi (2 – 6 Bar).

Although the machine will function properly at lower pressures, increased fill times will occur.

Flush the water system for at least two minutes prior or initial use.

Use flexible hoses and install separate screen filters in the lines to keep rust and other foreign

particles out of the solenoid valves. Hang the hoses in a large loop. Do not allow the hoses to link.

The water connections to the machine should be supplied by a hot and cold water line of least the

sizes shown in the table below. Installation of additional machines will require proportional larger

water lines.

Table 3-5 Water connection detail

NUMBER OF MACHINES

Pipe Size for HARDMOUNT Series

To avoid eventual water hammer in the water line, suitable devices to reduce the water

hammer should be installed.

Loading...

Loading...