INSTALLATION PROCEDURES

3-11

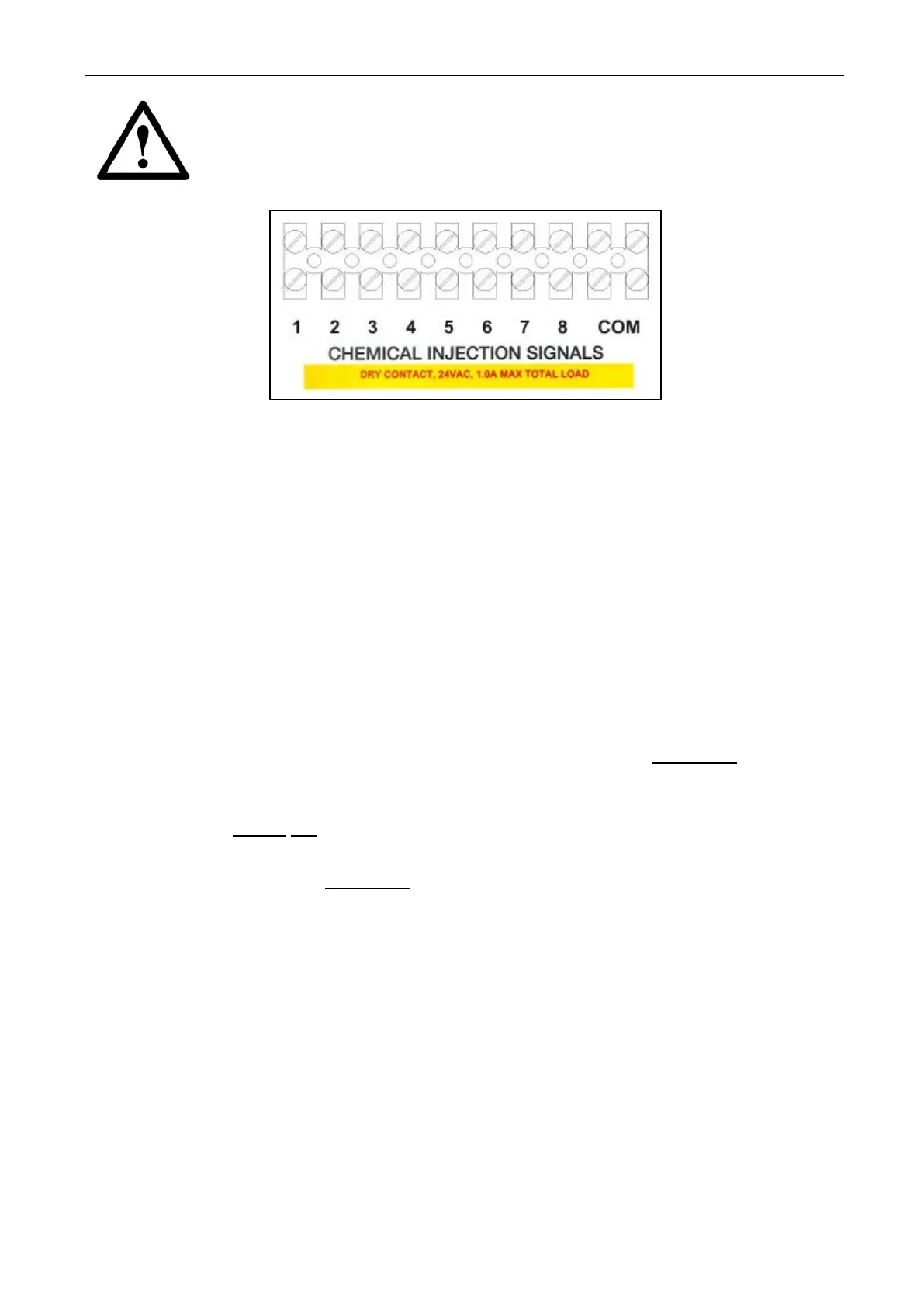

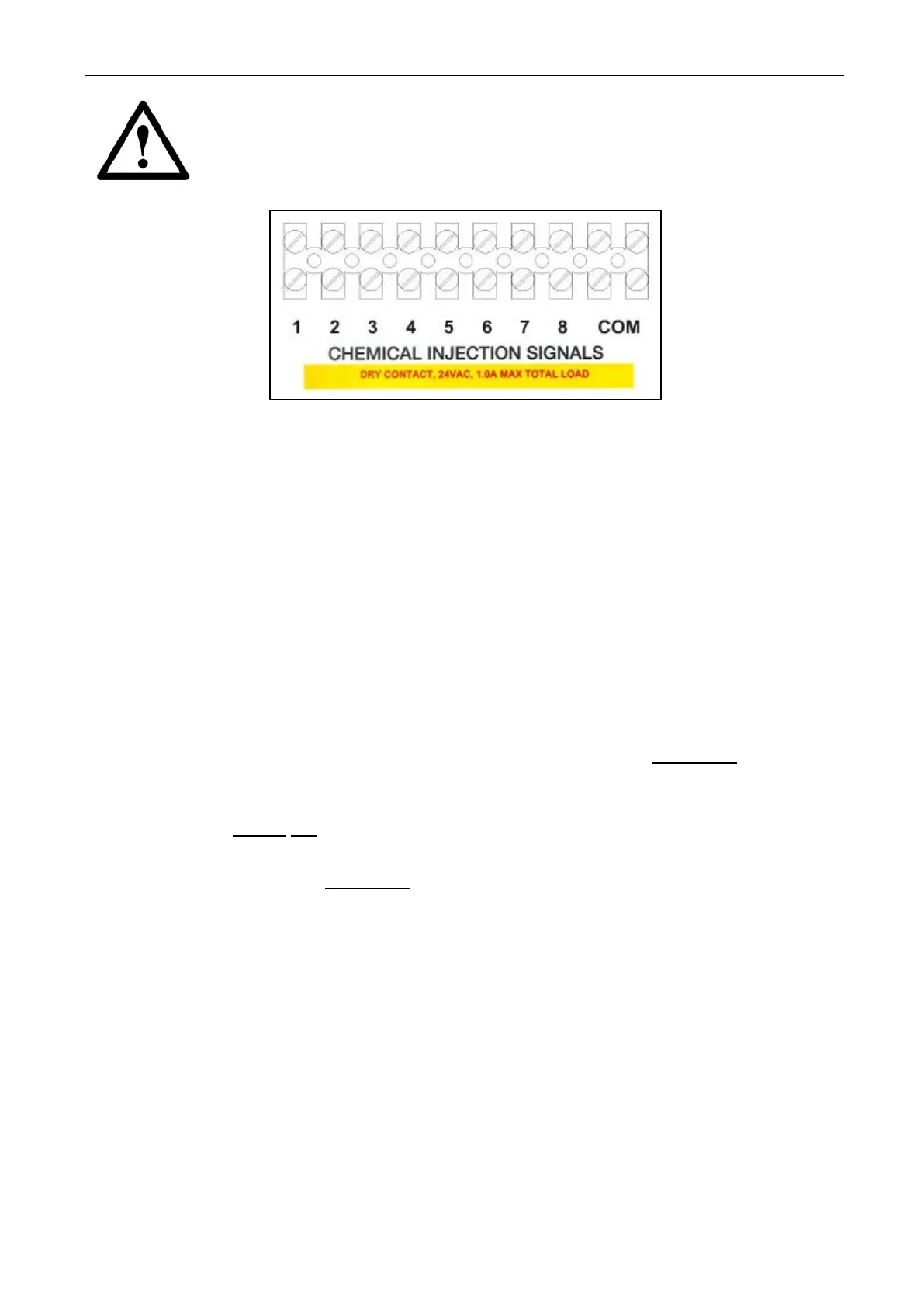

Attempting to obtain power from the machine terminals may damage the machine

circuit and/or the chemical injection system. Consult the chemical injection supply

system instructions for operational details.

Fig. 3-10 External chemical supply terminal block detail

3.9 CONTROL FUNCTION TEST

The machine should be cleaned after the installation is complete. A function test should

then be executed on the unloaded machine as follows:

1. Check the proper supply for such characteristics as correct voltage, phase, and cycles to be

certain they are correct for the machine.

2. Open manual shut – off water valves to the machine.

3. Press Emergency Stop button.

4. Apply power to the machine.

5. Release the Emergency button.

6. Check the door interlock before starting the machine.

a. Attempt to start the machine with the door open. The machine should not start with the

door open.

b. Close the door without locking it and attempt to start the machine. The

washer should not start with the door unlocked.

c. Close and lock the door and start a cycle. Attempt to open the door while the cycle is in

progress. The door should not open. If the door lock and interlock are not functioning

properly, call a service technician.

7. Cylinder rotation must be counter clockwise in the extract step. If rotation is not correct,

disconnect the power to the machine. A qualified technician must reverse any two leads

between the AC drive and the motor.

8. Cylinder rotation must be counter clockwise in the extract step. If rotation is not correct,

disconnect the power to the machine. A qualified technician must reverse any two leads

between the AC drive and the motor.

Loading...

Loading...