TROUBLE SHOOTING

7-6

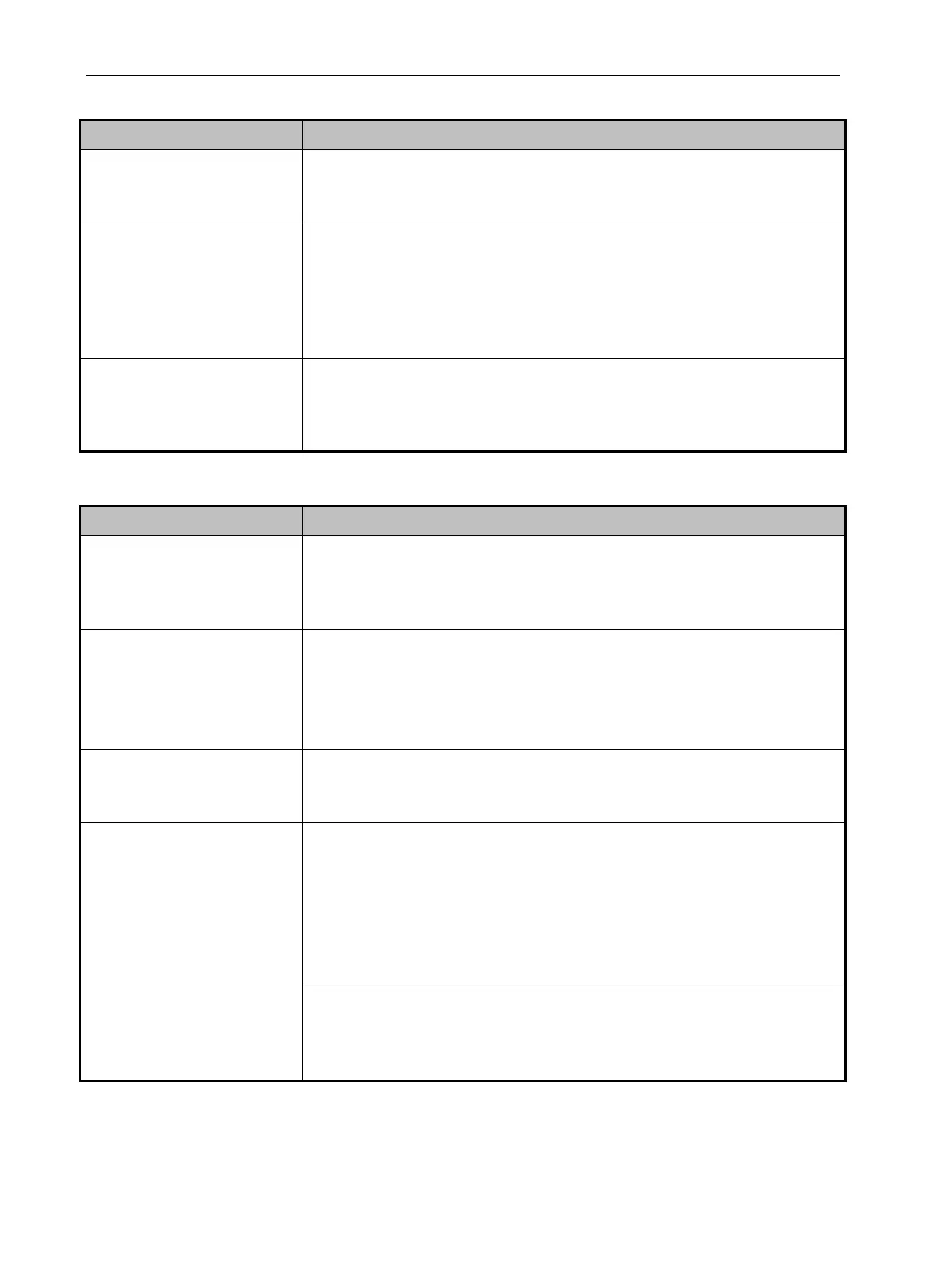

3. The motor runs in the opposite direction to the command.

Possible Causes What to Check and Suggested Measures

1. Wiring had been

connected to the motor

incorrectly

Check the wiring to the motor.

→ Connect terminals U, V, and W of the inverter to the respective U,

V, and W terminals of the motor.

2. Incorrect connection

and settings for run

commands and

rotation direction

command (FWD) and

(REV)

Check the data of function codes E98 and E99 and the connection to

terminals (FWD) and (REV).

→ Correct the data of the function codes and the connection.

3. The setting for the

rotation direction via

keypad operation is

incorrect.

Check the data of function code F02.

→ Change the data of function code F02 to 2 (forward rotation) or 3

(reverse rotation).

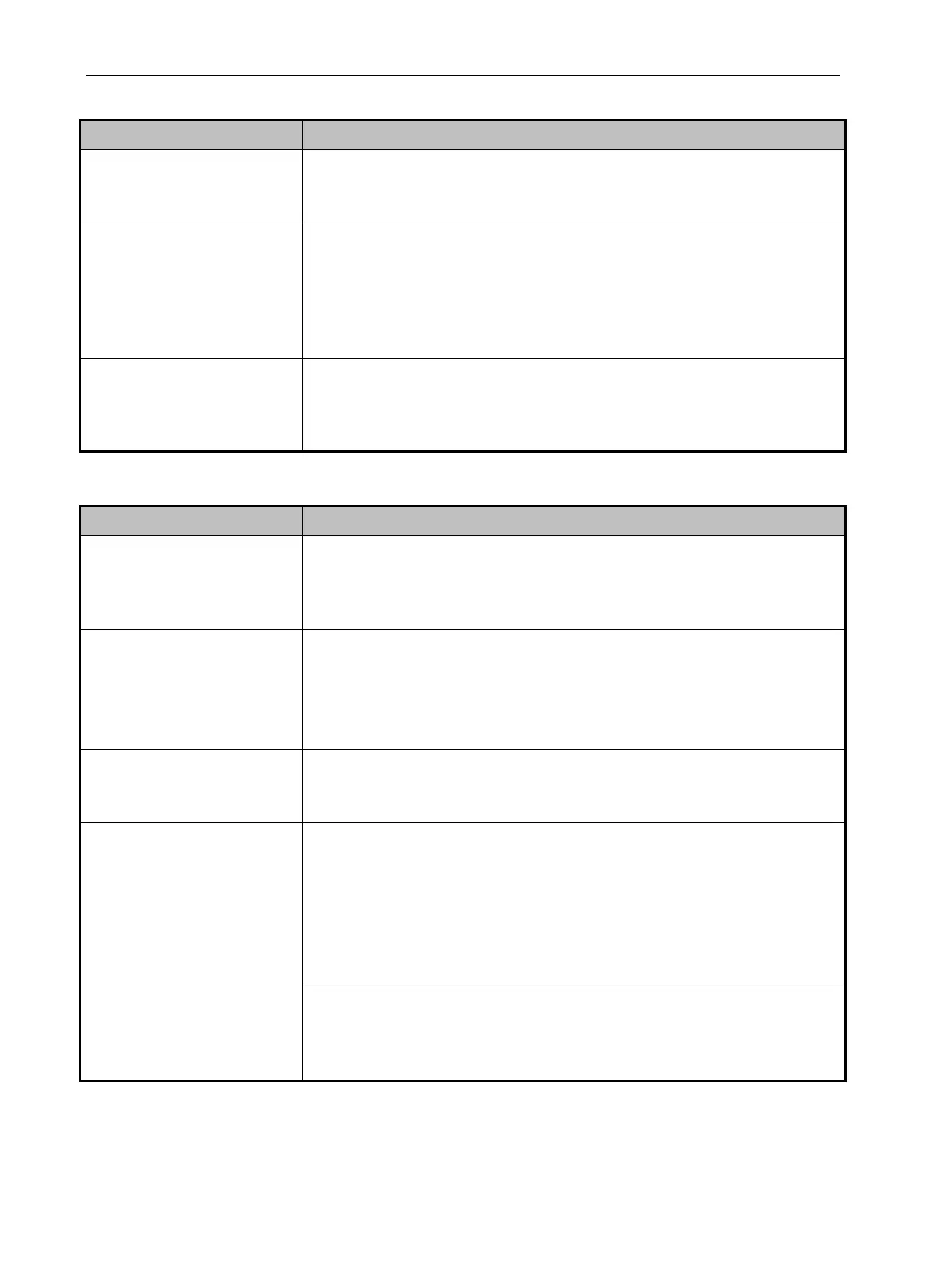

4. If the speed variation and current vibration (such as hunting) occur at the regular speed.

Possible Causes What to Check and Suggested Measures

1. The frequency

command fluctuated.

Check the signals for the frequency command with Menu#4 “I/O

checking” using the keypad.

→ Increase the filter constants

(C33 and C38) for the frequency

command.

2. The external

frequency command

device was used.

Check that there is no noise in the control signal wires from external

sources.

→

Isolate the control signal wires from the main circuit wires as far

as possible.

→ Use shielded or twisted wires for the control signal.

3. The slip compensation

gain was too large.

Check that the motor vibration is absorbed if the slip compensation

(P09) is cancelled.

→ Correct or cancel the slip compensation (P09) data.

4. The vibration system

having low stiffness in

a load caused hunting

or the current is

irregular due to special

motor constants.

Cancel the automatic control system (automatic torque boost, slip

compensation, energy saving operation, overload prevention control,

current limiting) and check that the motor vibration is suppressed

(F37, P09, H70, and F43).

→ Cancel the functions causing the vibration.

→

Readjust the data of the oscillation suppression gain (H80)

currently set.

Check that the motor vibration is Suppressed if you decrease the

carrier frequency (F26) or set the sound tune to level 0 (F27=0).

→ Decrease the carrier frequency (F26) or set the sound tune level 0

(F27=0).

Loading...

Loading...