PAGE 17

FOR SERVICE TECHNICIAN’S USE ONLY

DO NOT REMOVE OR DESTROY

4. Check P14-1 and P14-2 to dryer cabinet

ground. If either pin indicates continuity

to ground (short), replace wiring harness;

otherwise, proceed to step 5.

5. If the preceding steps did not correct the

problem, replace the CCU.

TEST #4b: Thermal Fuse

ELECTRIC DRYER: The thermal fuse is wired

in series with the dryer drive motor.

GAS DRYER: The thermal fuse is wired

in series with the dryer gas valve.

ALL DRYERS:

1. Unplug dryer or disconnect power.

2. Access the thermal fuse by removing

the front panel. See Dryer Disassembly

Instructions, page 24.

3. Using an ohmmeter, check the continuity

across the thermal fuse.

If the ohmmeter indicates an open circuit,

replace the thermal fuse.

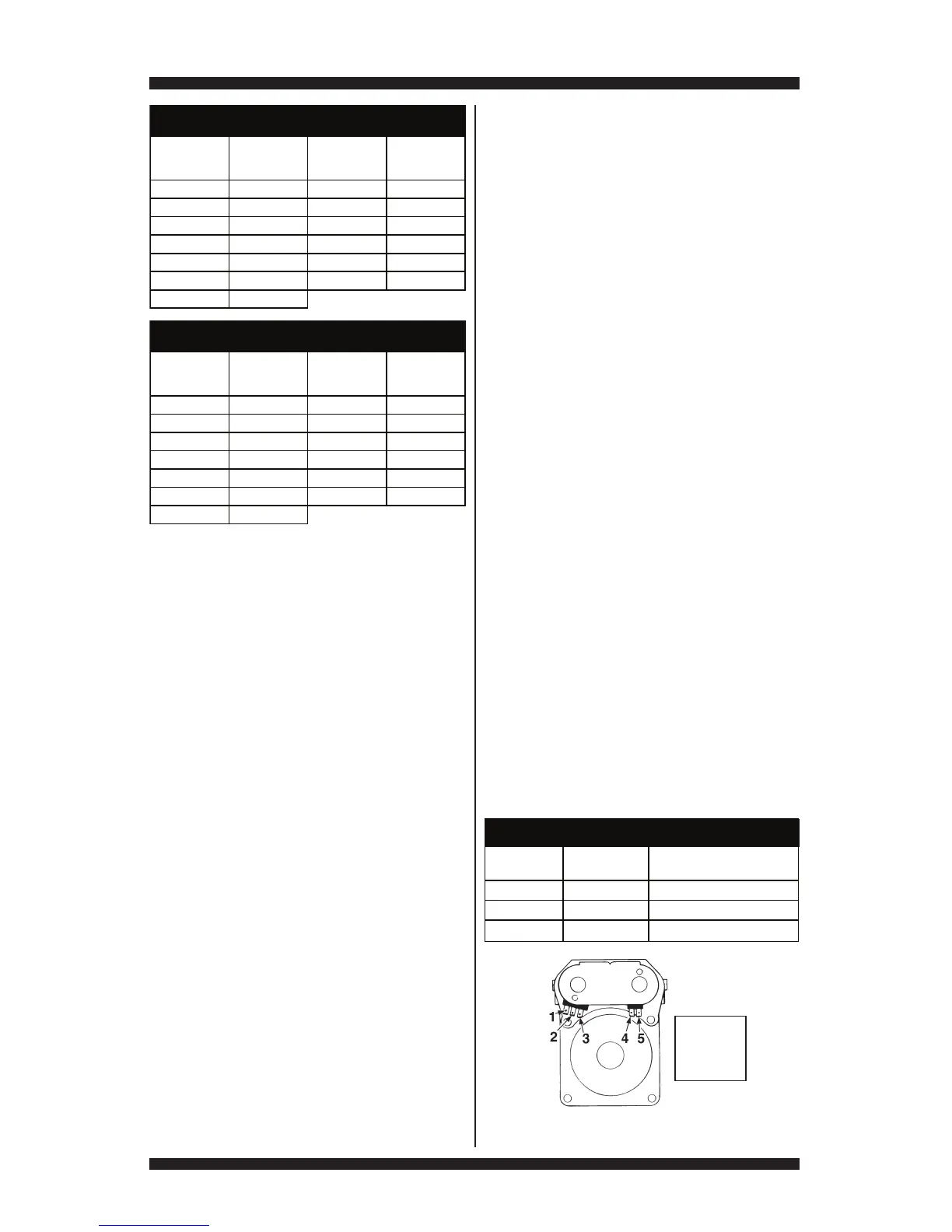

TEMP.

°F (°C)

RES.

RANGE

k ohms

TEMP.

°F (°C)

RES.

RANGE

k ohms

68° (20°) 61.2–63.7 131° (55°) 14.5–15.3

77° (25°) 49.0–51.0 140° (60°) 12.1–12.8

86° (30°) 39.5–41.1 149° (65°) 10.2–10.7

95° (35°) 32.0–33.3 158° (70°)8.5–9.0

104° (40°) 26.1–27.2 167° (75°)7.2–7.6

113° (45°) 21.4–22.3 176° (80°)6.1–6.5

122° (50°) 17.6–18.5

ELECT - INLET THERMISTOR RESISTANCE

TEMP.

°F (°C)

RES.

RANGE

k ohms

TEMP.

°F (°C)

RES.

RANGE

k ohms

68° (20°) 57.5–67.6 131° (55°) 14.1–15.6

77° (25°) 46.1–53.8 140° (60°)11.8–12.9

86° (30°) 37.4–43.1 149° (65°)9.9–10.8

95° (35°) 30.4–34.7 158° (70°)8.4–9.0

104° (40°) 24.9–28.2 167° (75°)7.1–7.6

113° (45°) 20.5–23.0 176° (80°)6.0–6.4

122° (50°) 16.9–18.9

GAS - INLET THERMISTOR RESISTANCE

TEST #4c: Thermal Cut-Off

If the dryer does not produce heat, check the

status of the thermal cut-off.

1. Unplug dryer or disconnect power.

2. Access the thermal cut-off by removing

the front panel. See Dryer Disassembly

Instructions, page 24.

3. Using an ohmmeter, check the continuity

across the thermal cut-off. See figures 20a

and 20b, page 14, for location.

4. If the ohmmeter indicates an open circuit,

perform the following:

ALL DRYERS: Replace both the thermal

cut-off and high limit thermostat. Also, check

for blocked or improperly installed exhaust

system, and, on electric dryers, for heat

element malfunction.

TEST #4d: Gas Valve, Gas Dryer

3Quick Check: Heater activation and

related component attributes are provided

in “Service Diagnostics ➔ Component

Activation ➔ Heat On.”

1. Unplug dryer or disconnect power.

2. Access the gas valve by removing

the back panel. See Dryer Disassembly

Instructions, page 24.

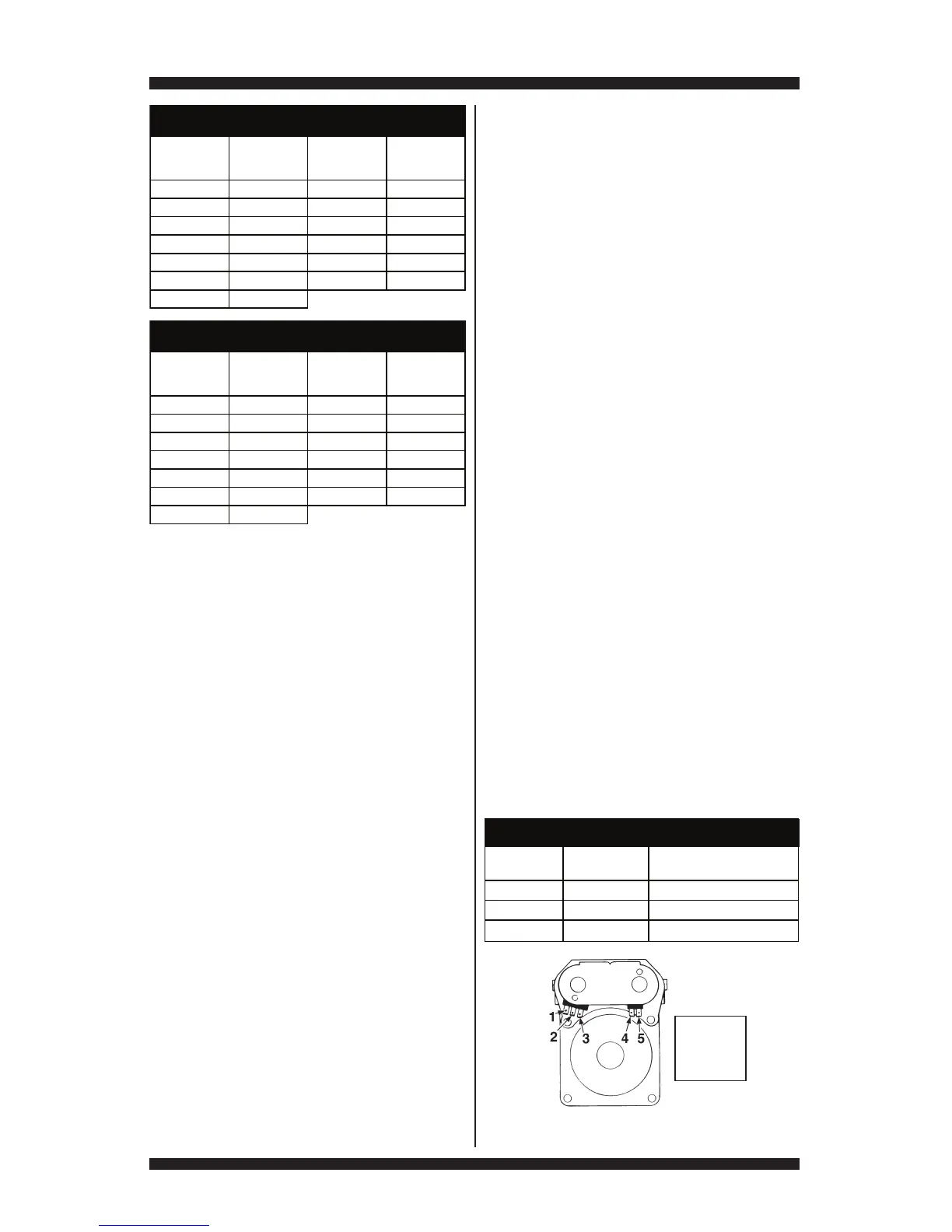

3. Use an ohmmeter to determine if a gas valve

coil has malfunctioned. Remove harness plugs.

Measure resistance across the terminals (see

figure 21). Readings should match those shown

in the following chart; if not, replace coils.

Pin 1 – Black

Pin 2 – Blue

Pin 3 – White

Pin 4 – Blue

Pin 5 – White

Figure 21 - Gas valve pinouts.

Coils Terminals

Resistance

in ohms

Hold 1 to 2 1400 ± 70

Assist 1 to 3 570 ± 28.5

Main 4 to 5 1300 ± 65

GAS VALVE RESISTANCE

Loading...

Loading...