A

DANGER -

A

ALWAYS STOP ENGINE AND DISCONNECT SPARK

PLUG WIRE AND MOVE ITAWAY FROM

SPARK PLUG

BEFORE PERFORMING ANY ADJUSTMENTS OR RE-

PAIRS.

WHENCLEANING, REPAIRINGORINSPECTfNGYOUR

CHIPPEWSHREDDER MAKE CERTAIN ALL MOVING

PARTS HAVE STOPPED.

TO REDUCE THE RISK OF INJURY, ALWAYS WEAR

HEAVY GLOVES WHEN HANDUNG THE CLflllNG

BLADES.- THE CUITiNG EDGES ARE

SHARP AND

CAN

CAUSE SEVERE INJURY.

SHARPENING OR REPLACING

CHIPPER BLADES:

Over a period of time, the cutting blade will dull. Sharpen or

replace the blade when the chipper no Iongw cuts as efficiently

as when new.

● Discard a cracked or severely nicked blade because it

could break apart and cause personal injury.

● Sharpen a blade that isdullorthat has only minor nicks; The

blade is made from tempered steel and is extremely hard -

do not attempt to sharpen with a hand file. We recommend

that you take the blade to a professional sharpening service

for proper sharpening.

Allgrinding must be done flat and

uniform along the beveled edge only, being sure to maintain

the orginal 45° cutting angle.

TO REMOVE AND INSTALL THE

CHIPPER BLADE:

Disconncd spark plug wire and move it away from spark

plug.

Ftemove the Chipper chute by removing three (3) hex nuts

and washers (iorns B). A 1/2” sockot with ~xtension is

required (Soo FIG.-3 ASSY).

Rota! e the Hopper assembly to the ground as shown in FIG.

3-OP.

Removo tho three (3) hex locknuts (item A) and flatwashers

(iem B) from the housing studserts and carefully separate

the Hopper assembly from the remainder of the unit (See

FIG. 2-SERV. & ADJ.)

Remove the three

(3) bushings (item C) and stationary

plate

(item D). (See FIG. 2-SERV. & ADJ) NOTE: When

reassembling, make certain the opcximg of the stationary

plate is toward the bottom of the unit and the offset, is facing

toward the impeller assembly.

Rotate the impeller assembly by hand until you locate the

Chipper blade in the Chipper chute opening.

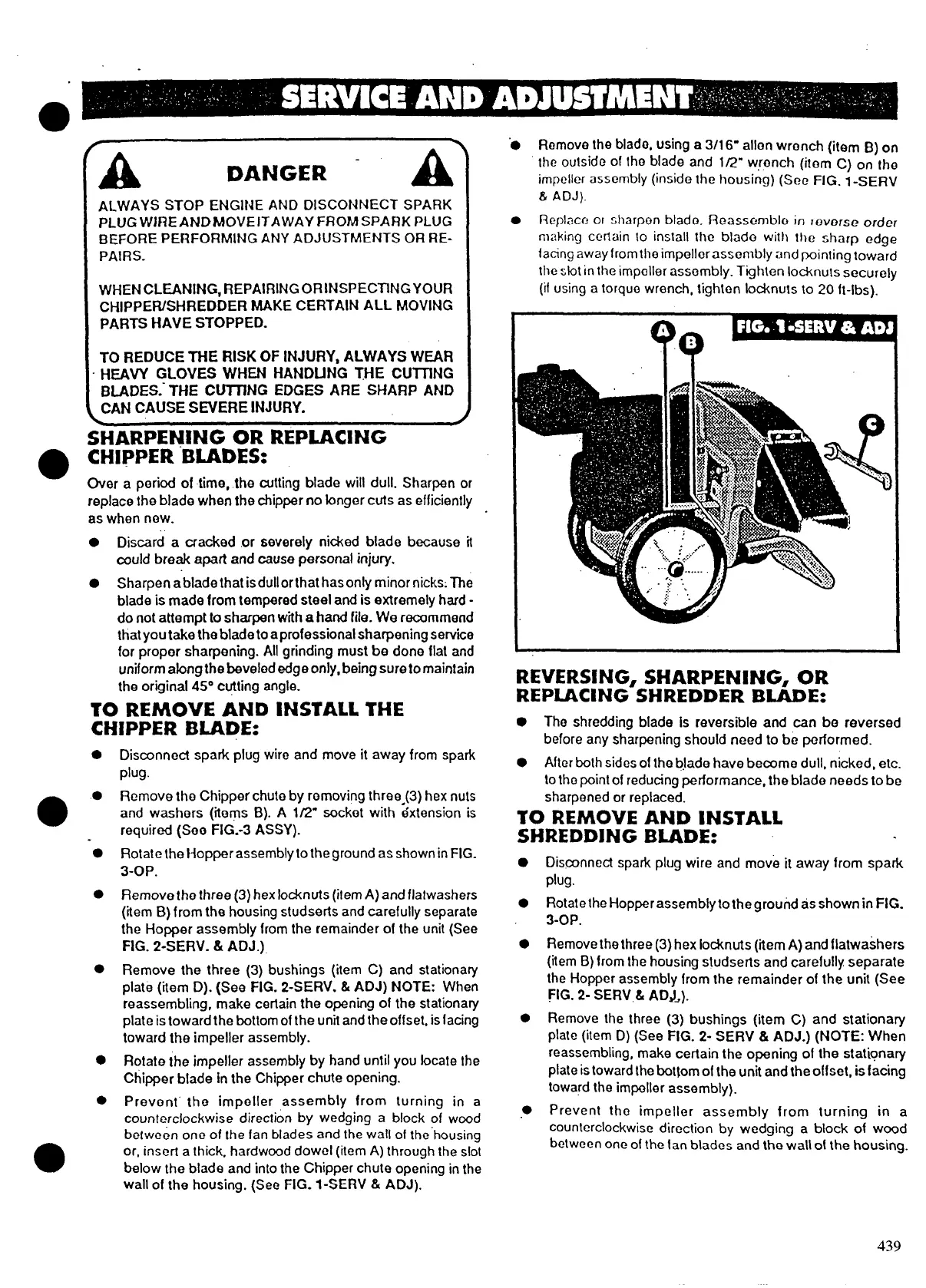

Prevent” the impeller ,assembly from turning in a

counterclockwise direction by wedging a block of wcod

be[wecn one of the fan blades and the wall of the’housing

or, insert a thick, hardwood dowel (item A) through the slot

below the blade and into the Chipper chute opening in the

wall of the housing. (See FIG. 1-SERV & ADJ).

● Remove the blade, using a

3/16- anon wrench (item B) on

the outside of tho bfade and 1/2” wrench (item C) on [he

impeller assembly (inside the housing) (See FIG. 1-SERV

&

AD.f).

. Replace 01 sharpen blade. f30assomblo in rowrse order

m;+king certain 10 inslall the blade with the sharp edge

facing away from the impellorassomtiy and pointing toward

the sfot in the impeller

assembly. Tghten locknuts securely

(if using a torquo wrench, tighten lo~nuts to 20 ft-lbs). -

● The shredding bfade is reversible and can be reversed

before any sharpening should need to be performed.

● After both sides of the blade have become dull, nicked, etc.

to the point of reducing performance, the blade needs to be

sharpened or replaced.

TO REMOVE AND INSTALL

SHREDDJNG BLADE:

●

●

●

●

●

Disconnect spark plug wire and move it away from spark

plug.

Rotate [he Hopper assembly totheground as shown in FIG.

3-OP.

Remove the three (3) hex locknuts (iem A) and flatwashers

(item B) from the housing studserts and carefully separate

the Hopper assembly from the remainder of the unit (See

FIG. 2- SERV,& ADJ.).

Remove the three (3) bushings (i[em C) and stationary

plate (item D) (See FIG. 2-

SERV & ADJ.) (NOTE: When

reassembling, make certain the opening of the stationary

plate is toward the bo[~om of the uni[ and the offset, is facing

toward the impeller assembly).

prevent the impeller assembly from turning in a

counterclockwise direction by wedging a block of wood

between one of the tan blades and the wall of the housing.

439

Loading...

Loading...