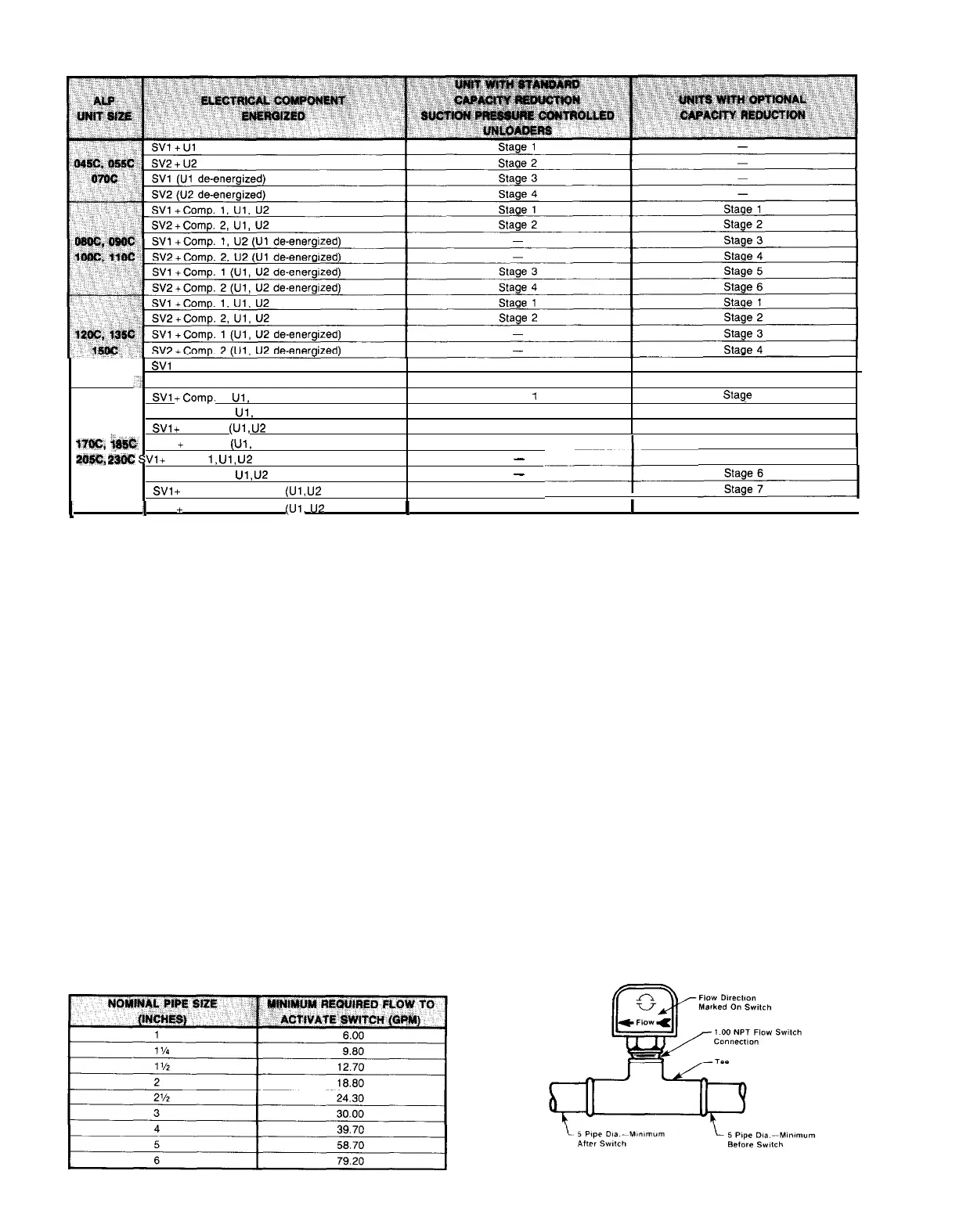

Table 18. Capacity reduction

SVl + Comp. 1 + Comp. 3 (R3 energized)

,‘:

SV2 + Comp. 2 + Comp. 4 (R4 energized)

SW

+Comp. 1,

Ul.

U2

SV2 + Comp. 2,

Ul,

U2

SVI

+

Comp. 1

(Ul,

U2

de-energized)

t7lac,

i

SV2

+

Comp. 2

(Ul,

U2 de-energized)

a?$#!&

m

SVl

+

Comp.

1,

Ul,

U2

+ Comp. 3 (R3 energized)

SV2 + Comp. 2,

Ul,

U2

+ Comp. 4 (R4 energized)

SVl

+

Comp. 1 + Comp. 3

(Ul,

U2

de-energized)

Stage 3

Stage 5

Stage 4

Stage 6

Stage

1

Stag-e

1

Stage 2

Stage 2

Stage 3

Stage 3

Stage 4

_I

Stage 4

-

..-_I

Stage 5

-

Stage 5

--

1

1

SV2

+

Comp.

2

+

Comp.4

(Ul,

UZ

Stage

6

Stage

6

de-energized)

1

I

I

NOTES:

1.

Compressor staging for units with suction pressure controlled unloaders and unloaders controlled from a remote source

(discharge

air, return water, etc.) is the same.

2. See page 54 for more information on unloaders controlled from suction pressure.

WATER PIPING FOR CHILLED WATER APPLICATIONS

Due to the variety of piping practices, it is advisable to follow the recommendations of local

authorities. They can supply the installer with the proper building and safety codes required

for a safe and proper installation.

FLOW SWITCH FOR CHILLED WATER APPLICATIONS

A WATER FLOW SWITCH MUST BE MOUNTED in either

the entering or leaving water line to insure that there will be

adequate water flow and cooling load to the evaporator before

the unit can start. This will safeguard against slugging the

compressors on startup. It also serves to shut down the unit

in the event that water flow is interrupted to guard against

evaporator freeze-up.

A flow switch is available from McQuay under ordering

number

860-175033B-00.

It is a “paddle” type switch and

adaptable to any pipe size from 1” to 6” nominal. Certain

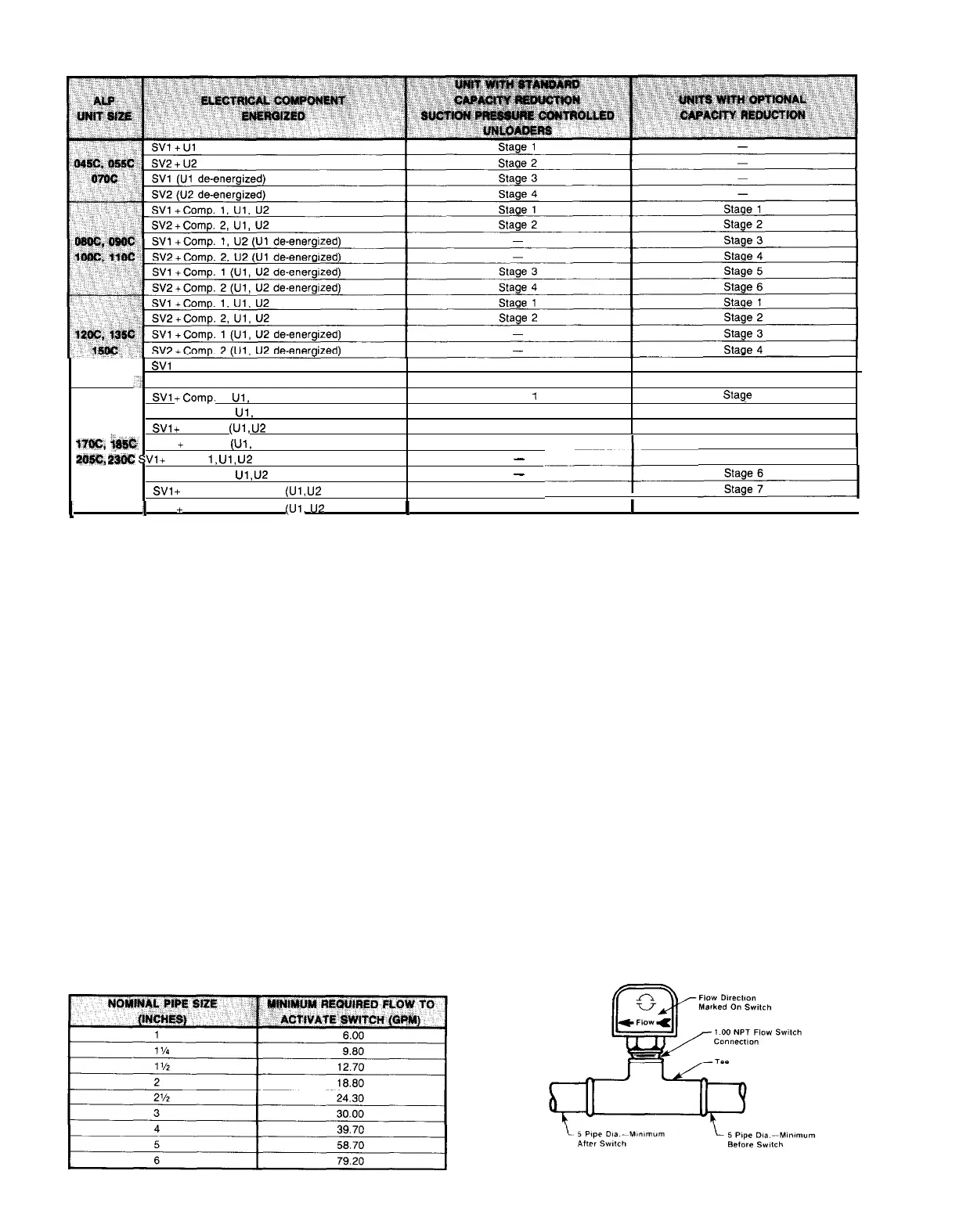

Table 19. Flow switch minimum flow rates

Figure 13.

Page 18 /

IM

269

minimum flow rates are required to close the switch and are

listed in Table 18. Installation should be as shown in Figure

13.

Electrical connections in the unit control center should be

made at terminals 5 and 6. The normally open contacts of

the flow switch should be wired between these two terminals.

There is also a set of normally closed contacts on the switch

that could be used

for an indicator light or an alarm to in-

dicate when a “no

flow” condition exists.

Loading...

Loading...