LOCATION

Care should be taken in the location of the unit to provide

Minimum clearances as shown in Figure 3 will prevent most

proper airflow to the condenser, minimizing effects on

con-

discharge air recirculation to the condenser which will have

densing pressure.

a significant effect on unit performance.

SERVICE ACCESS

Each end of the unit must be accessible after installation for

periodic service work. Compressors, filter-driers, and manual

liquid line shutoff valves are accessible on each side of the

unit adjacent to the control box. High pressure, low pressure,

and motor protector controls are on the compressor. Most

other operational, safety and starting controls are located in

the unit control box.

On all ALP units the condenser fans and motors can be

removed from the top of the unit. A complete fan/motor

assembly should be removed for service.

CAUTION: Disconnect all power to unit while servicing

con-

denser fan motors.

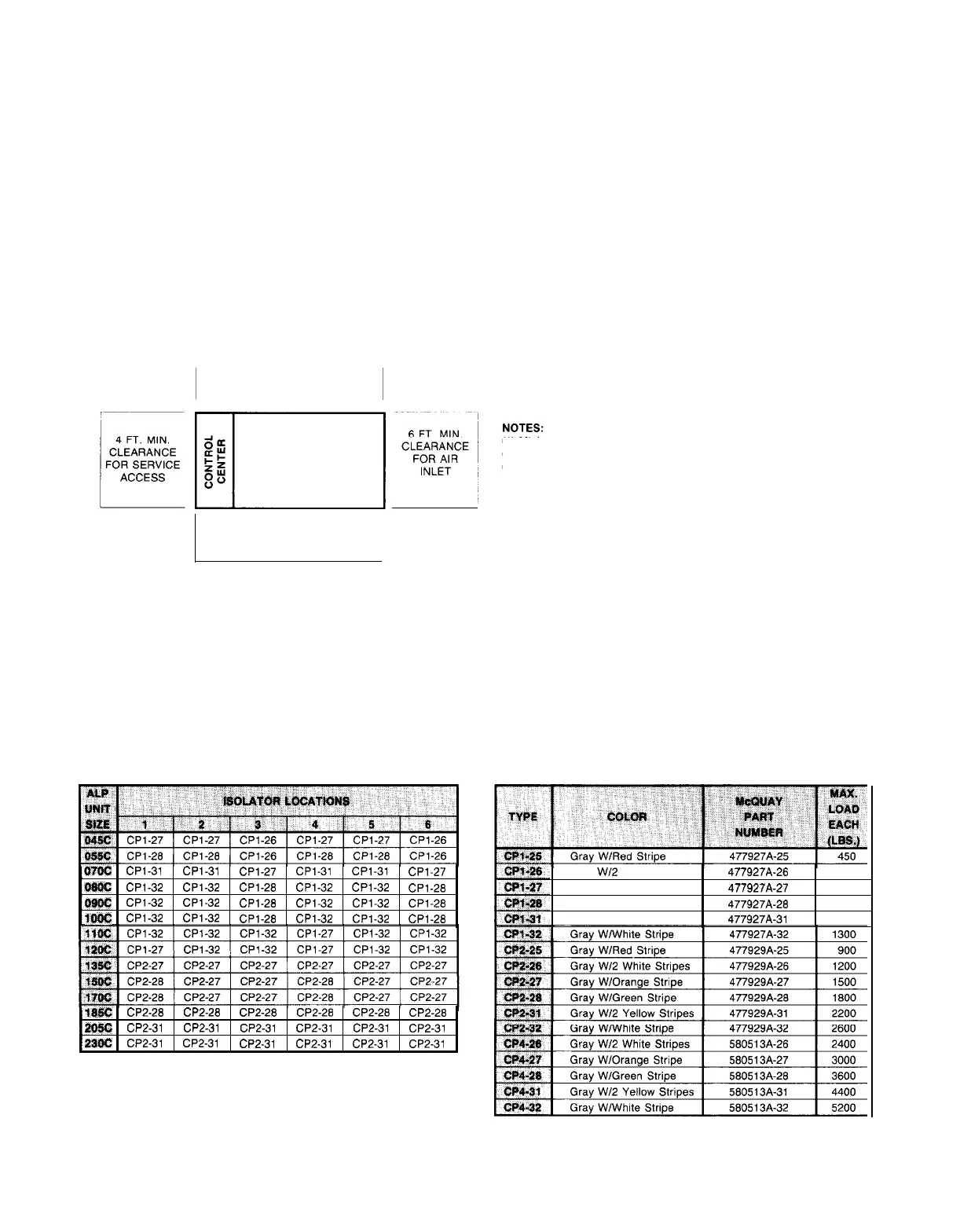

Figure 3. Clearance Requirements

ALP-045C

thru 230C

6 FT. MIN. CLEARANCE

FOR AIR INLET

(1) Minimum clearance between units is 12 feet.

(2) Units must not be Installed in a pit that is deeper than the height of the unit.

(3) Minimum clearance on each side is 12 feet when installed in a pit.

6 FT. MIN. CLEARANCE

FOR AIR INLET

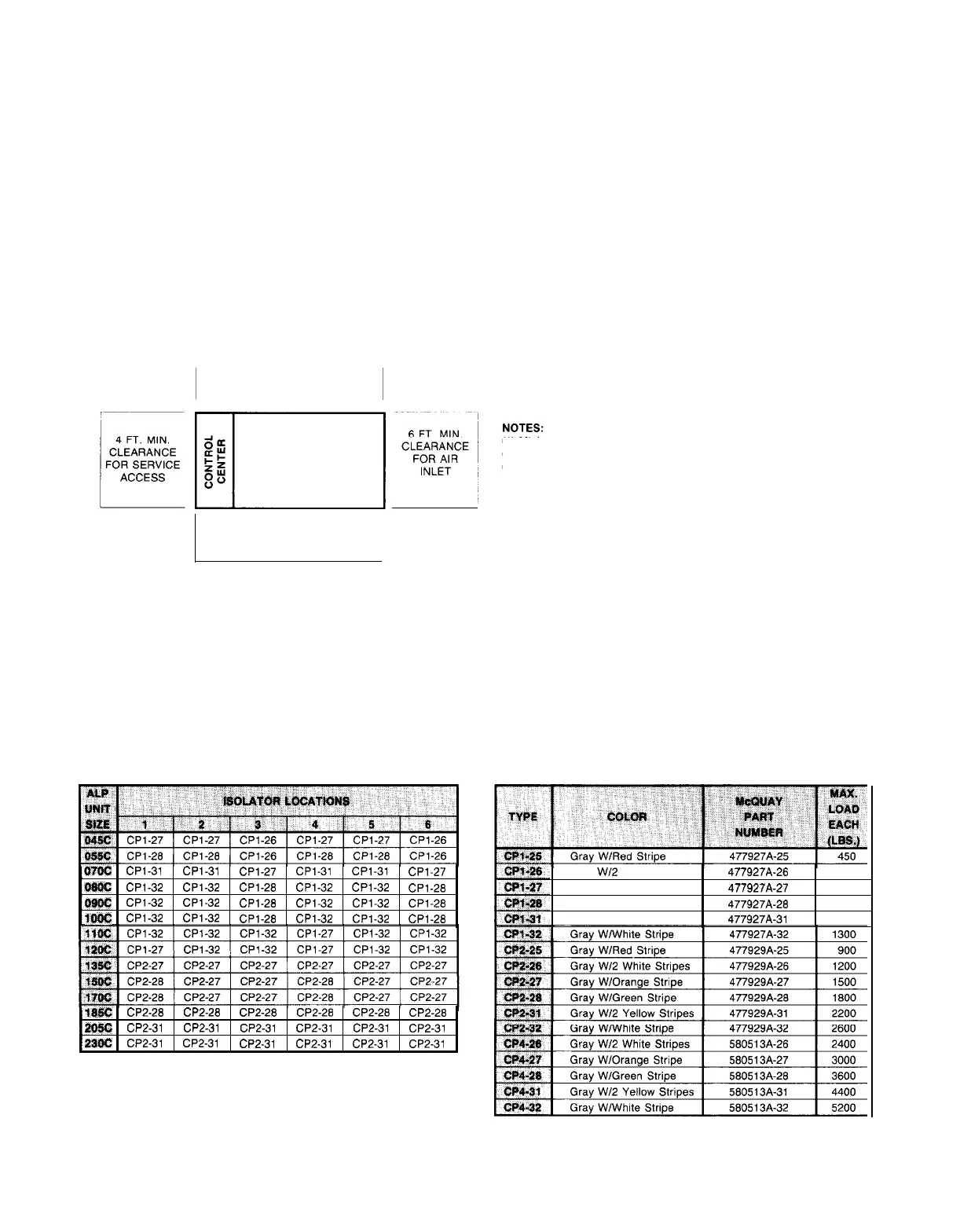

VIBRATION ISOLATORS

Vibration isolators are recommended for all roof mounted in-

stallations or wherever vibration transmission is a considera-

tion. Table 1 lists spring isolators for all ALP unit sizes. Figure

4 shows isolator locations in relation to the unit control center.

Figure 5 gives dimensions that are required to secure each

Table 1. Vibration Isolators (Spring)

Q?txJ

CPl-31 CPl-31

CPl-27 CPl-31 CPl-31

CPl-27

ioU@

CPl-32

CPl-32

CPl-28 CPl-32

CPl-32

CPl-28

OS@

CPl-32 CPl-32

CPl-28 CPl-32 CPl-32

CPl-28

low

CPl-32 CPl-32

CPl-28 CPl-32 CPl-32

CPl-28

?8W:

CP2-28

CP2-26

CP2-28 CP2-26 CP2-28

CP2-28

Z96Q

CP2-31

CP2-31

CP2-31

CP2-31

CP2-31

CP2-31

OgoC

CP2-31 CP2-31

CP2-31 CP2-31 CP2-31 CP2-31

McQuay isolator selection to the mounting surface. Table 3

shows the isolator loads at each location shown in Figure 4,

and the maximum loads for each McQuay selection are

shown in Table 2.

Table 2. Spring-flex Isolators

Gray

W/2

White Stripes

Gray W/Orange Stripe

Gray W/Green Stripe

Gray W/2 Yellow Stripes

477927A-26

600

477927A-27

750

477927A-26

900

477927A-31

1100

Page 4

/

IM 269

Loading...

Loading...